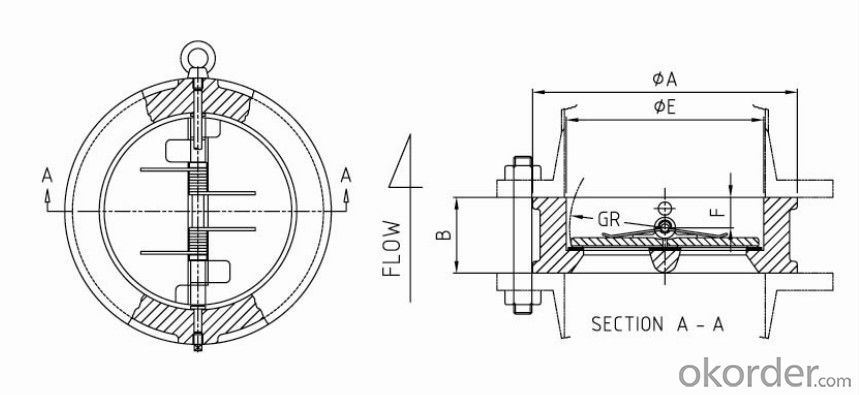

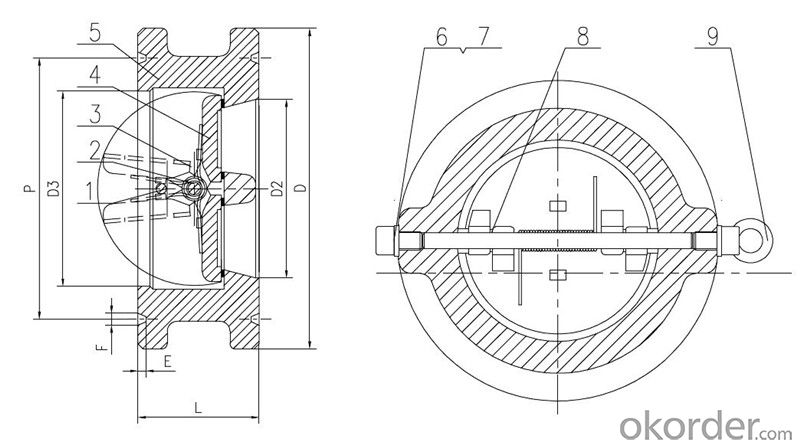

Swing Check Valve Wafer Type Double Disc DN 350 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Need some info. Ok, four valves per cylinder is better than two valves per cylinder. Fine, why did Ford REVERT to only 3 valves (my guess is to save cost SOHC)? Audi and VW are using five valves per cylinder on some cars, does this offer any advantage over a four valve engine? Maserati even experimented with a six valve per cylinder!!!! (see link) http://www.maserati-alfieri .uk/alfieri26.htm but abandoned it (my guess is cost again?) Why are we stuck at four valves or would more valves actually render more horsepower? Pop some ideas best answer to reasonable answer...

- There are multitudes of problems to resolve and strike a balance... ...In a zero valve, 2 cycle operation , clearing the cylinder of exhaust and recharge it is as basic as it comes..... ...In valved, 4 cycle operation, one valve each for exh and intake, has the least add-on linkages/cams , but limits the speed and completeness of clearing the exhaust and fully recharging the intake. By adding additional valving, the rapid removal of exhaust and recharging is accomplished, at great expense for add-on linkages/cams etc, and great loss of power...since you have many more items to accelerate and decelerate. The ideal valving, is to effectively remove the cylinder head for exhausting, and replace it for charging, but it would be a mechanical nightmare......therefore, compromises are made...2, 3, 4,6,....total head ???cost.. st...vs performance.

- Q: hi i have mitral valve prolapse/dysautonomia. when i get chest pains, its when i try to breathe. like i can take a little breath but if i take more my chest hurts. used to be pretty scary. i understand dysautonomia, but know know why it hurts to breathe in my heart sometimes. please help!

- Mitral valve prolapse is known to lead to chest pain, but the exact cause for the chest pain is not understood. The chest pain related to mitral valve prolapse is described as atypical, because it does not have the typical characteristics of other heart related pain. It is possible that your chest pain may or may not be related to your mitral valve prolapse. Chest pain that occurs or worsens with breathing is suggestive of a problem with the lining around the lungs (pleurisy.) A musculoskeletal cause like a pulled muscle is also possible. Anxiety would also be a possible cause. None of these conditions are serious. Chest pain resulting from MVP is not known to lead to any negative health consequences. Discuss it with your Cardiologist if you remain concerned.

- Q: HowdyWas taking apart a screw down NR valve and screw lift valve and noticed the spindles were made out of different materials. Brass and Steel.I am aware that brass is non corrosive but why use steel in the other valve? Is it due to their operation, do they come or not come in contact with fluids? Is one cheaper than the other?The screw lift globe valve had a steel spindle and the screw down nr glove valve had a brass spindle.Also, if anyone knows what materials are used in the valve lid and seat are made of.Any ideas?Cheers

- *In steam service , steam flashing is one of the factor which erode the spindle ( say valve stem) *The stem serves as a connector from the actuator to the inside of the valve and transmits this actuation force. Stems are either smooth for actuator controlled valves or threaded for manual valves. The smooth stems are surrounded by packing material to prevent leaking material from the valve. This packing is a wearable material and will have to be replaced during maintenance. With a smooth stem the ends are threaded to allow connection to the plug and the actuator. The stem must not only withstand a large amount of compression force during valve closure, but also have high tensile strength during valve opening. In addition, the stem must be very straight, or have low run out, in order to ensure good valve closure. This minimum run out also minimizes wear of the packing contained in the bonnet, which provides the seal against leakage. The stem may be provided with a shroud over the packing nut to prevent foreign bodies entering the packing material, which would accelerate wear. Disc material: Cast Iron or Ductile Iron Disc Aluminum-bronze Disc Stainless Steel Disc Nickel-plated Ductile Iron Lid material: engineering plastics, Cast Iron. Seat material[hard/soft]: Seats can be integral to the valve body, that is hard metal or plastic. *Hard seat: Hardened steel,Cast Iron,EN-52 forging steel Valve Seats are made from Chrome Alloy Steel which has a high wear resistance at high temperature. Nearly all metal seated valves leak, even though some leaks are extremely small. *Soft seats can be fitted to the valve body and made of materials such as PTFE or various elastomers such as NBR, EPDM, FKM. Each of these soft materials is limited by temperature (rough maximum temperatures are listed below) NBR 80 °C EPDM 120 °C FKM 170 °C PTFE 200 °C

- Q: I know i have to buy a recirculating valve but should i drop 250 on the perrin or will any brand do? how important is a high quality BOV?

- To correct alot of false answers here: DO NOT GET A BLOW OFF VALVE. A Recirculating valve is called a Bypass Valve. All Blow Off Valves go to the atmosphere. The only reason to get a new Bypass Valve is if you are running a bigger turbo and the stock one starts to leak. Im running 20psi on my stock turbo and the stock bypass valve holds fine.

- Q: I want to put a blow off valve in my car to make it sound cool lol but i dont have a turbo yet ... do i even need one?

- Without a turbocharger there is nothing to blow off. Like asking if you need a lamp to use a light bulb.

- Q: We had a sprinkler zone that did not send much water to sprinkler heads. Checked the spring on the solenoid. We took off the top of the valve and rinsed gasket and parts below – put back together. The zone then worked. However I then noticed that the valve that does not shut off completely – water meter shows usage. I turn off water as it comes from the house.We then replaced the solenoid, the zone would not turn on. When back to the old solenoid. I switched wires at the timer and valve, it started, but when the cycle was through there still was water going through the system. Put wires back to their original locations.Space is crowded and looks tricky to replace valve. Would like advice on that for next year. However my main concern is when we shut down for the winter. We manually run each of the 8 stations and blow out the water. Will the bad valve cause a problem?

- If there's water going through the valve when it's in the off state, the valve seat or seal must be worn or damaged. If it's the valve seat, you'll likely have to replace the valve. When you say manually run each [station] and blow out the water, are you using compressed air? Otherwise, it's not clear how running water would blow out the water. In any case, if the valve in question opens, it should allow for your blowing out process, and if the water is shut off completely at the valve, no water should get in to refill the pipes.

- Q: like they say on 4 strokes you gotta go get valve jobs, and they cost bout 300 they say? well what does the mechanic do? can it be done at home and your just adjusting them?

- A okorder /

- Q: Where do I get a electric valve with a 120 VAC coil

- Cheapest okorder /... Grainger being a major supplier of parts - note the high cost of many of these because of being high temp steam and hot water under pressure and look for other choices.

- Q: This trumpet has been in storage in its casing untouched for about 5 years. I took it out and tried to play it but only air comes out and no sound. The 2nd and 3rd valves are hard to push down. What do I do to fix it? Thanks!

- its your lips...lol you/I can make a trumpet sound off with just the mouthpiece alone.... try again

- Q: why do new motorcycles need to get their valves shimed alot? can someone explain how the whole valve adjusting thing works? why do some engine types require more attention? i have owned thumpers my whole life and never really thought about it. i was looking at this like cheap beater bike (hyosung gt250 v twin) and i read the valves need to be checked like 3 times in a short span, wtf??

- Valves have to have some clearance when the engine is cold so that as the stems expand the valves will still close all the way. Most of the wear in the valve train occurs at the valve and seat, as the seat tends to recede and the valve pulls further into the head.(SOHC and OHV designs may also wear in the rocker arms and bushings, which tends to open the valve clearances, usually not as quickly as valve seat wear, however.) As an inevitable result of this wear at the seat/valve juncture, the gap between the valve stem (or bucket or shim) and the cam lobe (or rocker arm) tends to close down. If the gap is too small, the valve may not close all the way when the engine is warm. If the valve does not have enough contact with the seat, it cannot transfer heat away, and may erode. There can also be a loss of compression if the valve cannot close. This wear happens most rapidly with a new engine and the valve clearances tend to close up relatively quickly. As the parts bed in, clearances tend to stabilize. That is why the first one or two valve adjustments are most important.

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 350 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords