API Cast Steel Check Valve Flange RF in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

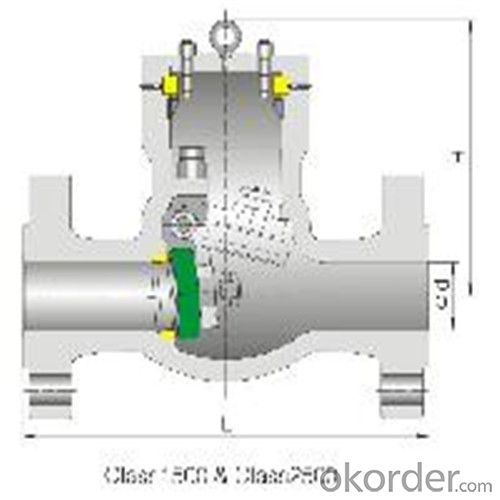

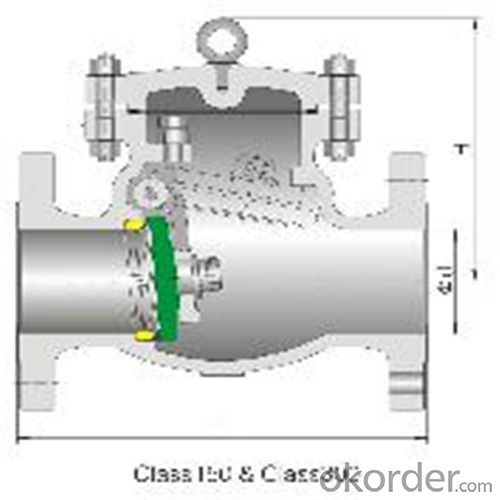

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Okay, I got this lawnmower its a craftsman with a briggss and stratton engine, and I use this mower to cut grass in the summer. My question is, I have to get this mower serviced like every 2 weeks. See, the problem is always the valves comes out of adjustment. It only has 2 valves, and a long time ago, I broke one of the studs for the valves. And some guy put another valve on it. Ever since then it hasnt ran good. Iv'e took it many times to get it worked on, and it will run great for about 2 weeks. Then the valves go out it's very hard for it to turn over, and it wont run. Whats the deal here? I hear that you should only have to adjust your valves once a year. What could be wrong?

- haha they have been given me 2 valves briggs and value trans will bypass next shrink your cost now sorry I hate craftsman now they bit me and distinctive others guess ur mower is green with the cup holder,

- Q: Looking at a few marshall amps and i came across this whole valve amp thing. I've heard about it before, but never really understood it. What types of valves are there?! (i think i've heard of power amp valve) and what type of marshall amps have valves?! Can some of them be part valve and then have that valvestate thing?! :s all pretty damn confussing Cheers

- Marshall were big name in Amps when pretty well everything electronic used valves. Some valves were quite small, some larger, and some are still used today in powerful transmitters. There are those who swear that the sound produced by a valve amplifier is far better than a solid state one. Valve technology takes up much more space than solid state, so miniaturisation is a problem, and also uses much more power and produces a lot of heat. Now solid state is capable of producing high power audio amplifiers which use less power and take up less space, so have become the preferred method. Nevertheless, there is a strong following even today for a good high powered valve amplifier. And yes, it is quite possible to have a valve and solid state mix. The solid state works at the input stage, and the valves take over at high power output levels, but I am not sure what the purists would think about this hybrid usage .

- Q: Hey I'm high rite now and i have a checkup for mitro-valve prolapse tomrow, i was wondering if they will take my blood and see THC in me....

- Mitral okorder

- Q: can a person survive with only one heart valve functioning?

- Everyone has correctly identified that there are 4 heart valves. The question of survival is producing a variance in the responses. This may be because you do not define what you mean by 'not functioning'. People may do reasonably well - at least initially - with varying degrees of stenosis and / or regurgitation of more than 1 heart valve. So Yes in a sense if I understand your question correctly a person may survive at least temporarily with only one heart valve functioning perfectly. Please bear in mind that you have not given much information for me to work with in answering your question. If I may be of further assistance please let me know. I wish you the very best of health and happiness and in all things may God bless. JR

- Q: I'm looking for a valve that can be electronically controlled to open and close with a diameter of 1.5'(inches) to 2'(inches) and this valve must be able to withstand 20psi. Any websites or listings of stores I can go to would much appreciated. Thank you

- If you are looking for just an open or shut valve, not a 0-100% control, there are many sources. Slone (spelling), or almost any industrial supply house will have an assortment of sizes and voltages. I f you want to do 0-100%, consult scientific supply houses like Fisher Chemical Company. They will have an assortment of valves with controller systems.

- Q: Do blow off valves serve any purpose besides making the hiss when you shift? how much does one cost?

- Blow-off valves only work on turbocharged or supercharged engines. It is an intake manifold pressure regulator. I've seen people put them on regular engines thinking they would hear that hiss, but there is no where near enough pressure for them to do anything.

- Q: Ok, so I was just wondering, do you have to have a turbo to get blow-off valves? Also, do you have to have a manual? And are there any other requirements?

- A blow off valve releases the excess pressure from your forced induction system when you close the throttle plate. It prevents turbo surge. If you install one on your naturally aspirated vehicle, all it will do is get you laughed at. As for the manual, READ IT! Blow off valves have nothing to do with the transmission, so automatic or manual, makes no difference. Word of advise: Don't work on or modify your car. You'll make it slower at the very least.

- Q: In place of actual valve oil, can I use WD40? How about baby oil? Are there any household products which work?

- Trumpet Valve Oil

- Q: Defects in which valves would produce the following?1) SEVERE DEPENDENT EDEMA?2) PAROXYSMAL NOCTURNAL DYSPEA3) CONGESTED LIVER?4) DISTENDED JUGULAR VEINS?5) PRODUCTIVE COUGH WITH FROTHY SPUTUMfor 1. i believe it's tricupsid valve, 2. mitra valve please correct me if I'm wrong. Thaanks!

- 1. Would require dysfunction on a valve in the right heart generally speaking, so the options would be the likes of tricuspid regurgitation or stenosis, or even pulmonary stenosis. 2. PND is a result of heart failure, particularly regarding the left side of the heart (although of course both sides could be failing). Many valve problems could cause this as an end result... a bit of an odd question, but I'd go with mitral stenosis or regurgitation primarily. 3. Congested liver is the systemic blood system overload (like the oedema), so it is the right heart. Triscuspid regurgitation can cause a congested liver and if you felt this liver, it would be pulsating too. 4. Distended jugular veins are a sign of heart failure. Primarily right heart failure as it is causing blood to be backed up instead of passing through the right heart to the lungs. Tricuspid stenosis or plain old right heart failure (with or without left heart failure at the same time). 5. This is typical of left heart failure as blood backs up into the pulmonary system as the left heart is failing to pump into the systemic circulation. Similar things to PND can cause this. These questions though, are honestly a little on the vague side and half those cases would result from heart failure even without any valvular abnormalities...

- Q: I am a 55-year-old female going in for mitral valve replacement surgery, and I need to decide on which valve to get: bovine or mechanical. If you have any experiences or know anyone who's had either of these types of valves placed in their bodies, please elaborate on the experience. I want to know the pros and cons of each.Thank you.

- Mechanical valves require lifelong anti coagulation. This can cause problems of compliance (Forgetting to take the medicine), longer time to heal for cuts, and potential internal bleeding problems especially for women. They have a very long life. Current bio prosthetic valves have improved considerably in durability. They do not require continuous anti coagulation. They do tend to calcify. This may not be a problem 55 years and above. These valves also have better blood flow characteristics. These are the general considerations. Individual bio chemistries vary widely. Your surgeon and cardiologist are the best fit to suggest what is best for you.

Send your message to us

API Cast Steel Check Valve Flange RF in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords