API Cast Steel Check Valve Flange RTJ in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

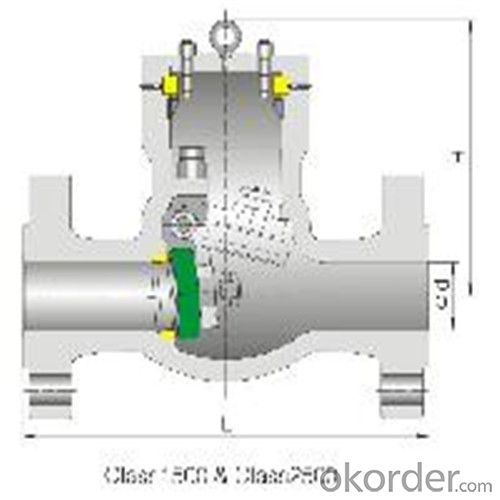

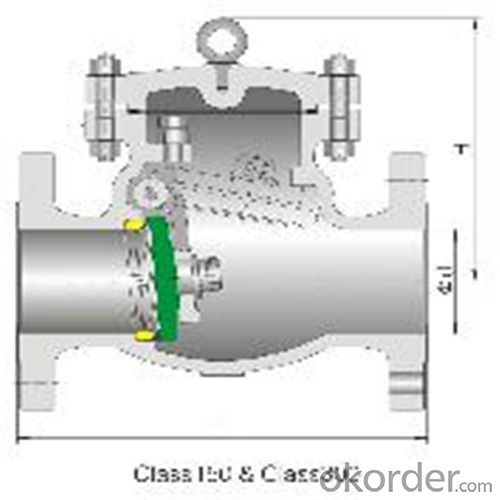

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Does anyone out there have any tech info or schematics for state of the art camless engines that run pneumatic valve train?

- the valve train is run hydralicly off a second oil pump,you cant use air as it compresses and would not allow for exact valve timimg,many new big diesels run this way

- Q: my inflatable kayak has a self bailing drain valve. it says to close the valve in lakes and streams to stay completely dry and open it in oceans or mild whitewaters.whats the point of this valve? i WANT water to come in??

- Self Bailing Kayak

- Q: I am looking at getting a baritone horn of my own, but am not sure what compensating versus non-compensating valves are?

- A compensating valve instrument has valves that send the air through two sets of tubing. For example a double French horn has slides for the F side and the Bb side. In a normal horn the air goes through the F side when you are playing the F side and the Bb side when you are playing that side. In a compensating horn when you play the F side the air goes through both sets of slides. It's a way of making the horn lighter and simpler.

- Q: My husband went to the doctor today, then called to say he won't be coming home because he has infective endocarditis. They sent him to another, larger, hospital in the region. Hours later he called and said that he needs surgery on the valve and they are moving him to another part of the country. I've been trying to read about it but I'm not sure I understand. What I've read says that they have to treat the infection with penicillin first, the he can have surgery. However, he's telling me he might have surgery when he get to the other hospital. He needs a new valve. Does this mean that his condition is worse than those I've read about or that they are simply doing things differently? Also, if you know. Does other illnesses make the risks much higher? He's got aspergillus in his lungs and have had 2/3 of the lungs removed. He has an immune deficiency (HIES) and he is physically weak from being sick. I know it's not good, but how bad is it?

- There are risks in any surgery - no matter how major or minor. Overall health condition also plays an important role in his recovery. Being he has an infection which could be life-threatening, treating him and having him go through this procedure gives him more chance of survival. The doctors have weighed the pros and cons of him having this procedure and feel this is the best way to proceed. They will do their best to help and take care of him.

- Q: My mother was dx'd with Mitral Valve Prolaspe 20 years ago....she use to take meds for it. My question is she is having very bad fatique symptoms.. uld this be caused from her MVP getting worse???

- Some okorder

- Q: I have a 40 year old Holton Bb trumpet. It plays fine except the first valve always gets stuck when I play it, in the middle of a song it won't come back up. I can pull it back up and it doesn't get stuck real bad, but how can I fix this? I always oil it properly and insert the valves right. Do I have to replace it? Thanks

- You need not replace the valve, but it does need a bit of attention. There are many possible reasons for the sticking and you can spend a long time trying to chase them down. Inconsistent sticking suggests 2 likely reasons (there are several more possible reasons). The first is piston wear that has slightly misshapen the valve casing so it sticks because it doesn't travel through the valve casing exactly the same way every time. The second is that the felts and corks are worn and need to be replaced. The best thing for you to do is to take it to a shop, describe the problem and spend a few bucks to get it fixed right.

- Q: ok so the water main that comes into the basement the valve handle snapped off so how do i shut the water off so i can replace that valve? I called the water company and they said they cant shut off the supply to the house because it is private property and we have to call a plumber if so how can they shut the water off and on if we dont pay the bill?

- The water company should do it?? But a plumber can do it to

- Q: I went to turn the water off with the shut-off valve so that I could do some work on the toilet tank (replacing old and leaky fill valve) but the water won't shut off. I'm assuming that I'll need to replace the shut-off valve itself but could anything else be causing the problem? The funny thing is, the leaky fill valve that I wanted to replace has now stopped hissing and leaking and the tank seemingly fills fine. But of course the water can't be turned off completely.Just wanted to check make sure that there aren't anything else I should do or consider before I went off to replace the shut-off valve.Thanks

- the shut off valves are soldiered on or threaded on it depends on which 1 you got. it might be easier to get a valve that looks like yours and putting the guts out of the new 1 into the old 1. as long as you can shut the water off to the valve

- Q: what to use to inflate self sealing tube with the presta valve?

- Gazoo If you do not have a pump that will accept a presta valve, then you can either buy a presta schrader pump, or a presta valve adapter. I have an adapter in each of my seat bags, they are only a buck or so, and will allow you to use service station air on your trips. Just cause you may not know, the presta valve has a rotating screw inside the valve. So to add or release air you must take your fingers and twist on that knurled circular end so that the presta valve extends away from the valve stem. Then when the tube is filled, twist it back tight to seal it off. Soccerref

- Q: I have pressure steady at 13psi --- water temp is normal range but the external emergency run valve has been dripping since i turned the boiler on this year? Expansion take was empty, so I forced water through and then drained it and reopened the valve.....I am stuck and getting concerned. Anyone have a suggestion?Would really apprecite it?Additional info:Boiler is a Gas Powered unit by MASTER from the 80's.....

- The TP valve will naturally wear out over time, if it has never popped open the washer inside of it has hardened, when you opened it it didn't seat properly when it closed back up, causing the drip. This is not an unusual or dangerous condition, the TP valve will usually wear out before the boiler does, it can be quickly and easily replaced. The valve will still function with a leak, but this reduces the efficiency of the boiler. DO NOT, under any conditions, DO NOT plug the leak by plugging the opening on the valve, this creates the potential for a very dangerous condition, let it drip until it can be replaced.

Send your message to us

API Cast Steel Check Valve Flange RTJ in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords