API Cast Steel Check Valve A216 WCB Body Material in Accordance with ISO17292、API 608、BS 5351

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

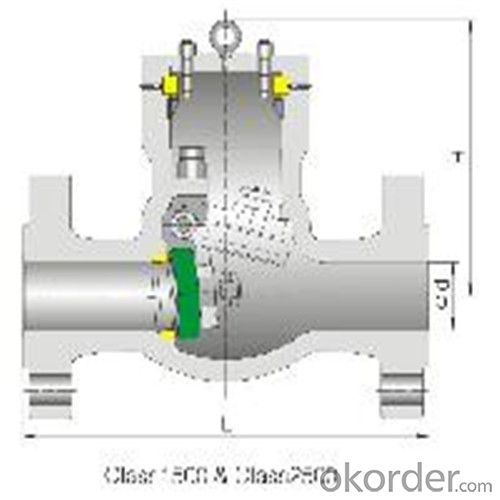

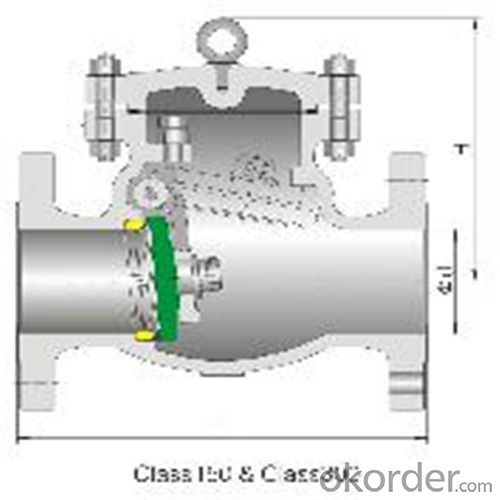

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: The automotive machine shop who is working on my Corolla head and block said that one of the valves was severely burnt. What causes burnt valves???

- This Site Might Help You. RE: What causes burnt valves? The automotive machine shop who is working on my Corolla head and block said that one of the valves was severely burnt. What causes burnt valves??

- Q: Among butterfly,ball,needle and gate valves which is used mostly in pneumatic system?

- It depends on what sort of system you are operating. Most butterfly valves leak, a few don't. Ball valves are instant operation, and don't normally leak. Needle valves are used for fine control of the flow rate. Gate valves are quick to operate, and don't normally leak. On aircraft pneumatic systems, butterfly valves are common, where a leak is permissable. Where no leak is permissable, slide valves are used, which have rubber seals.

- Q: A reading from my 2002 ford explorer said insufficient flow from the EGR valve. Would it be possible to clean the valve or fix it or would I need to buy a whole new valve?

- It probably has nothing to do with the actual EGR valve itself, there is a sensor called the PDFE, it monitors the flow of the egr valve, the flow is probably fine and the sensor that monitors it has gone bad, It is a VERY common issue on fords. I would start there. Good luck PS ford has an updated part number for the sensor so get it from the dealer

- Q: Ford Capri 2.8 injection. I need to adjust the valves, so need to know how to tell if the valves are tipping and at what exact time I need to adjust them.

- valve tapping what is valve tipping search yahoo answers for valve tapping i saw a resolved question about how to fix this problem

- Q: My 10 year old boy was diagnosed with a leaking heart valve yesterday.The Doctor is trying to get him in to see a specialist asap.She didn't seem that concerned with it,but I don't know if she was just trying to keep us calm about it.How serious is this,and is surgery the only way to fix it,or do they have meds for this condition.

- People with leaking heart valves usually see a cardiologist, who is a heart specialist. What they usually do is what is called an ECHO, which is a type of ultrasound of the heart. This can tell how bad the leak is.You have valves in each side of your heart, they function to help your blood flow correctly through your heart when it beats. If the heart valve is not leaking a lot, they usually monitor it with repeat ECHO's. If the leaking is such that you get short of breath, tire easily or other such things, they may recommend surgery. This is usually the only option, there is not medication that can fix the problem. If surgery is needed they will replace the valve. If surgery is needed the cardiologist will refer you to a cardiac surgeon. Ask questions. You need to see a specialist and then they can better explain all of this for you. Be heart healthy.

- Q: any flash files explaining valve operation maintenance will be very much helpful

- Pressure okorder /

- Q: I just fixed a clog in my bathroom sink by taking off the p-trap. I had turned off the water valve beforehand, and when I was done I turned it back on. After this, all that came out of the faucet was a trickle. Turning the valve in the off position does not stop the trickle. When I first turned the valve off before taking off the pipe, the valve was not turned all the way left or right. It was in the middle, but the water flowed fine. When I turned the valve all the way to the right, the water shut off at the faucet. My apartment is pretty old. Is this valve most likely broken?

- Like the first person said, put it back in the original middle position. It could be a ball type valve, meaning it has a ball with a hole in it. To the far left or far right the hole to allow water to go through would be against the pipe wall, not allowing water through. In the middle, the hole would be aligned with the pipe wall and let water through. If that doesn't work, it is likely broken, especially if the valve was wanting to stick hard beforehand or you felt a quick breaking feeling as you were turning it. Valves rarely totally break like that. But it can happen. My guess is you most likely have it in the wrong position. If it is broke, you'll have to turn the water off further up the line if you can or turn all of the water off if there isn't another shut-off valve to cut water pressure to the line. I would think there should be another shut-off valve some up the water line.

- Q: What is a valve adjustment? I wanted to do one on my 1994 Honda civic ex cuz my friends told me I should do one but I wanted to know howmuch will it cost? And what will it do to my car in performance and gas consumption? My car right now has 155k miles.

- Don't bother if you really don't need it (or don't know what it does). As cars get old, parts wear out and need to be adjusted. The valves open and close to let fuel in and exhaust gas out. unless you are suffering from some problem you don't need it. ==== I have 1994 Civic EX also. The good news is that the valves are very easy to access so the labor is cheap (no new parts unless the valves are really worn. good Luck P.S. My 94 Civic still runs like new and get great MPG. So if you get good MPG and have decent power, you don't need valve adjustment.

- Q: i know its going to drop some oil, im just wondering to what extent? how much oil is going to spill out?

- Oil will not run everywhere. If you do happen to see a drip, simply wipe off what you see.

- Q: I need to make a ball valve that will open with no manual force but by a motor of some sort to spin it and release water. how do i make a ball valve controlled by preferably a motor or other CHEAP device. I need to do this for less that 20$

- It's a lot easier and cheaper to buy the valve at a hardware store than make it. You can probably get a motor and gear train from a hobby store. If it doesn't absolutely have to be a ball valve, you can get electric sprinkler valves from just about any home and garden supply. They're specifically designed to control water flow. Just hook it up to a power source and you're good to go. Addition: Just remembered, you can also get battery operated water control valves that connect between a faucet and a hose. I'm pretty sure they're ball valves internally. Prices vary, so shop around. Depending on how fancy you want it to be, they go for about $5.00 and up.

Send your message to us

API Cast Steel Check Valve A216 WCB Body Material in Accordance with ISO17292、API 608、BS 5351

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords