API Cast Steel Check Valve Butt Welding in Accordance with ISO17292、API 608、BS 5351

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

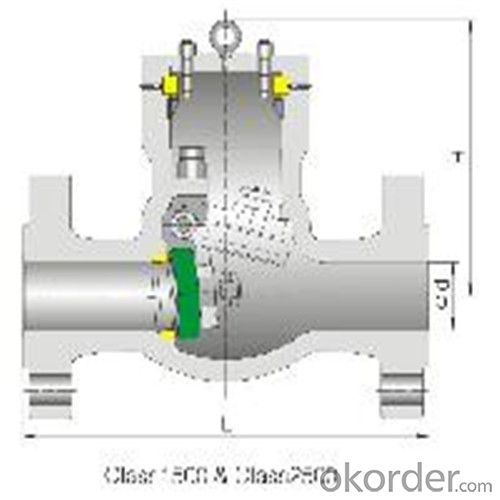

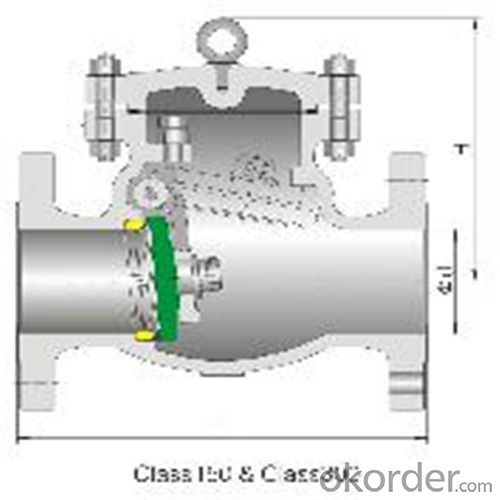

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: my check engine light just came on and i have some oil on the block of my engine, a friend told me that the valve cover gasket needs resealed. could that be why my check engine light is on?

- I assume you checked the oil level. You can go to Auto Zone and have engine codes checked for free to see if you have a problem. I can't see how a leaky valve cover would cause the check engine light to come on unless it fouled some sensor but then again I'm no mechanic.

- Q: Need some info. Ok, four valves per cylinder is better than two valves per cylinder. Fine, why did Ford REVERT to only 3 valves (my guess is to save cost SOHC)? Audi and VW are using five valves per cylinder on some cars, does this offer any advantage over a four valve engine? Maserati even experimented with a six valve per cylinder!!!! (see link) http://www.maserati-alfieri .uk/alfier... but abandoned it (my guess is cost again?) Why are we stuck at four valves or would more valves actually render more horsepower? Pop some ideas best answer to reasonable answer...

- Think of an engine as an air pump - obviously, we want the least amount of restriction for the incoming air and also the least amount for exhausting the compressed air. The ideal situation would be to remove the head during the intake stroke and put it back on during the compression stroke, but, obviously, this isn't possible. On a naturally aspirated engine, the intake is the most critical because the air is moved only by a relatively small difference in pressures. The exhaust stroke, on the other hand, is aided greatly by the super heated temperature and rapid expansion of the gasses. Two intake and one exhaust valve seems to be the most practical and efficient solution - adding more vales means smaller valves and an increase in the overall complexity. I seriously doubt that Maserati ever abandoned ANY automotive idea due to cost restraints. It's far more likely that adding more valves than three or four simply resulted in diminishing returns. Sometimes the allure of a new buzz phrase is nothing more than a marketing ploy - a 16 valve, DOHC, four cylinder engine, for example, is a pretty impressive resume for an engine, regardless of whether it actually is the optimum performance set up or not.

- Q: I was just informed that my 4 year old daughter has been diagnosed with mild mitral valve regurgitation. I have been researching, but only find the information to apply to adults, not children.What general course is taken when dealing with children with this condition and what should I expect? Her pediatrician was treating her symtoms as asthma with breathing treatments, but, I was not comfortable and took her to my family physician, who sent her for the echo, which discovered this.I'm more or less just looking at our options...

- my nephew had it and needed surgery.

- Q: Is there any application usuage of ball valve in comparison,most engineers opinion is as Valve size get reduces in reduced port.Other than this what paramteres decides in selection of either of one

- W.W. Grainger out of Chicago ships all over the world, also McMaster-Carr Supply.

- Q: I have a 4 diameter column of water 10' tall (filled with water). I need to find a flush valve unit to fit into the bottom of it so that it will flush all of the water out of the column in 1 flush. Essentially this will act as a large toilet but it is for a design project at school. My concerns are that the flapper will close before the water is completely flushed out of the column. Is there any way I can make the flapper stay open thus flushing all the water in column out without holding the chain connecting the float to the flapper valve?

- Flapper valves are all about weight and pivot points and center of gravity. The air bubble inside the plug acts like a ping pong ball initially, holding the flapper open. When the water gets down to the level of the flapper, it tends to close too soon as you point out. But you can attach a smal plastic cup to the back of the flapper that fills with water and holds the flapper open when the water level is very low. You put a small hole in the bottom of the cup so that the water in the cup slowly drains out and finally the cg shifts and the flapper closes.

- Q: 1990 Pontiac Sunbird, I took a piece of hose going to the egr valve to try and see if it is working properly, but with car off, I can suck through, and blow out into hose going to egr valve, and it doesn't seem like there's any seal stopping air flow either way...is it supposed to, or what is this supposed to do?

- It would be best if you could test the valve with a vacuum tester but from what you describe it is probably bad. The EGR has a diagram (basically a rubber disc) in it which can go bad when this happens the vacuum from the motor can no longer activate it. The biggest problem you may notice from this is you now have a Vacuum leak causing your motor to run lean. Many people would just plug the vacuum line to the valve to prevent the Vacuum leak and not worry about the valve. If you want or need to keep the emissions working on the car buy a new valve.

- Q: I've been working on cars since around march of 2012. I new. I have a set of 305 heads that were really dirty. It came from a 79 camaro that never had an Oil change. I took the valves out and the valves are pretty burnt. I was wondering If I cleaned them up would they still be good to use? The edges aren't rough or anything. Just let me know what is need to know please. The heads I know are still good.

- Not really. If you got the head off, you should replace them.

- Q: where is the fuel tank selector valve located on the truck?

- Fuel Tank Selector Valve

- Q: Where is the mixer valve on a '94 Dodge Caravan with a 3.0 V6 engine?

- if it is a fuel injected vehicle and i'm pretty sure it is. It is a computer controled system you have to take it in to get adjusted.

- Q: On a Chevrolet truck with a V8...One valve cover has a PVC valve and the other a push-in breather. Would it hurt to put a second PVC valve in so I have one on each side and run 3/8 hose to a T fitting then to the carburator? Good/Bad/Wouldn't hurt?

- I own a shop, and understand the system. You must have a filter on one side that allows air to flow into the crankcase, while a metered (PVC) amount is pulled through the engine for a complete evacuation of the crankcase. If you tie both ends together, you would have no air flow through the engine. What it would do is; build up pressure inside the engine, and force the oil out every seal, and crack in the engine. In othe words, it would use oil in a bad kind of way. Air must enter the engine, travel through the engine, and go back through the combustion side of the engine, and exit out the exhaust system. The vacuum inside the crankcase is a different system than the combustion side. If an engine does not create the correct amount of vacuum inside the crankcase, the piston rings will not seal as they should, and allow combustion to enter the crankcase building pressure. The PVC valve is a metering check ball that allows air to flow one way, but not the other, thus hooking a hose between the two sides will not allow the engine to ingest fresh air from any where. The vent cap for one side is a filter, and allows the fresh air to enter the engines crankcase. The air travels through the engine and evacuates the blow by gases from the piston rings. Equal amounts of pressure on both sides of the rings is what keeps the gases from just blowing past the rings. A pressure is actually built up between the top, and the bottom rings that make the rings expand and seal off even better. Upset this pressure on either side of the rings, and you have an engine that uses oil. It will either burn the oil, and/or throw the oil out of the engine. Its not really complicated how the system works, but disrupt the flow, or not have an equal amount of pressure on both sides of the piston rings, and you will have an unhappy engine. This applies to stock engines that come from the factory with a PVC system. Glad to help out, Good Luck!!!

Send your message to us

API Cast Steel Check Valve Butt Welding in Accordance with ISO17292、API 608、BS 5351

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords