API Cast Steel Check Valve 150 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

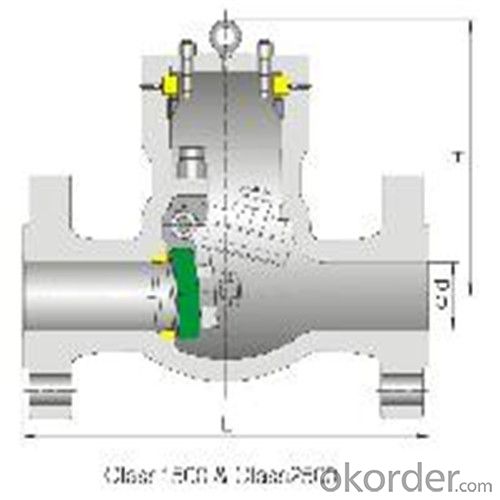

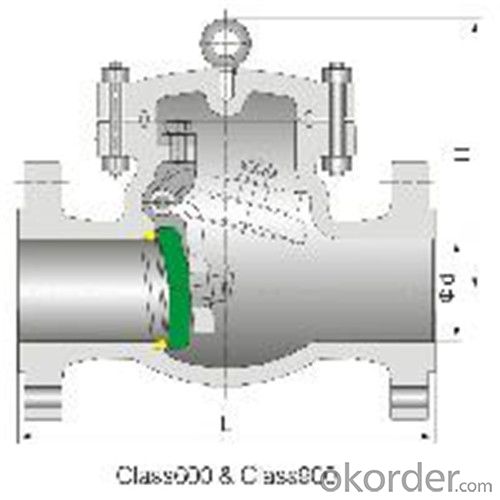

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Hi i have a 00 bmw 320d and am trying to find out information on puting a dump valve in, is it possible?, what type of dump valve? and how hard it would be to put in?? any help would be much appreciated.....Thanks!!

- Most diesels do not have throttle valves (including yours), therefore a blow off valve would never work. They work by relieving the pressure build up caused when the throttle valve is closed (foot lifted off gas pedal in a petrol engine), which happens when you shift (usually only for manuals) so the built up pressure does not bring the turbo speed down. A side effect of this pressure being dumped is the whoosh sound, which some people desire more than the performance gains it offers. That sound is the air rushing out of the intake system, which usually has been metered already, and now is wasted. The ECU measures that air and adds fuel for it. When it gets blown to atmosphere, the fuel is added, but not the air. Now the engine is running rich. There are some systems that recirc that air back to the turbo, but then there is no whoosh sound. Anyway, since most diesels do not even have a throttle valve, it won't do any good.

- Q: Anyone know how to stop this from happening? I have gone through 4 since March.

- are you sure its the egr valves going bad or not the egr solenoids causing you to get the code,that will make it appear that an egr has gone bad when it really hasn't,good luck.

- Q: Is there a more technically correct name for a valve that slowly opens, allowing increased pressure in a water line without blowing the end off?

- I've always known them to be simply called motorized valves, but they aren't specifically made to prevent instantaneous pressure build up. They are usually installed as a convenience type of thing and in lieu of solenoid valve which WOULD be an almost immediate full pressure situation, but any valve other than a solenoid activated one will allow for slow build up of pressure. A motorized valve just lets you do it automatically and you don't have to be right at the valve location to open it. Al

- Q: Hey I'm high rite now and i have a checkup for mitro-valve prolapse tomrow, i was wondering if they will take my blood and see THC in me....

- Mitral okorder

- Q: Im trying to make an apparatus that would allow you to breathe in from one tube and exhale through another is their a valve that does this. I originally thought that a one way valve might work however I cannot find one that works with suction.

- If I get your idea right, you would have two separate one way valves, one in each tube, facing in opposite directions. When you inhale the valve that opens provides air from that tube and the other one remains shut because the suction is pulling it closed. When you exhale, the inhale valve is pushed closed by the air pressure from your lungs and the exhale tube valve opens from the pressure provided by your lungs. Consider spring loaded valves if there are problems with the pause inbetween enough positive and negative air pressure in the tubes.

- Q: Or is our money stinky? is the $59 we paid not equivalent to that paid by xbox360 ps3? Please help!! I am sick of getting killed every 5 minutes. Is VAC false advertising?

- VAC takes time, it's not instant. That, or you suck.

- Q: wife died at 40 still awaiting results of exsaminers report. Can CPR be given to some one with two artificial heart valves mitral and arotic? She the person administering CPR be aware that they are in the heart...

- Yes, and it doesn't matter if there are artificial valves or not. The thing about CPR is that it's only done for someone who is actively trying to die. The alternative to doing CPR is to let someone pass away, which is not usually the best course of action (unless they have a terminal disease and have asked not to be resuscitated.) If you are asking whether the presence of heart valves excuses someone from NOT doing CPR... then no. If you are asking whether heart valves + CPR and a bad outcome is because CPR should not have been done, then no to that too. The right thing to do for someone who is pulseless is to start CPR, call 911 and get more definitive treatment on the way. CPR is not going to revive someone - it is only a bridge until a defibrillator and/or cardiac drugs are available. I'm sorry that you lost your wife at such a young age, and I hope you find the answers you are looking for.

- Q: I have a D16Z6 SOHC VTEC engine in my 93 Honda Del Sol.Ive been told that the D16Z6 came with 2 different valve covers. One style cover says Honda on the top and another also says VTEC.I have the one that just says honda but I want the other put on.What would I need to swap them, and where would I get them?and a roundabout price

- I don't think they sell any aftermarket valve covers that say Honda VTEC since companies would have to pay honda to use the name and i did a quick search but I could not find 1 cover for you vehicle which means you'd have to call the junk yards around your area or just call Honda and see if they can order one in for you, i doubt they have one lying around on a shelf it will take anywhere from 2 days to a week to order in and since its factory honda part its probably around 200$ without the gasket(maybe abit more) but if you swap it for a new one I suggest you do the gaskets and grommets with it so it won't leak oil. It's pretty fairly easy to change yourself, they are all top nuts or long bolts that run through the cover if i remember either 10 or 12mm, or both sockets required, when you get all the nuts off you simply just pull off the cover, it might be abit stuck so you can pry gently with a small screw driver or small prybar and it will come off, cover the top with a clean cloth or newspaper so no dust and rocks fall in, clean the metal area off of all the oil and youll see small corners that have abit of silicone on it, thats for extra protection so it won't leak out of the corners so just a small amount of black silicone dab in the same corners then put the new cover with gasket it on and tighten down, and just snug the bolts, theres no need to tighten the crap out of it or you might snap a bolt. 3/8 drive wratchet is okay to use. ( if you get some junkyard valve cover DO NOT paint it unless you have special heat ressistant paint or it will peel off and look really ugly ) Good luck....

- Q: I have a Ford Explorer 4x4 2004 model.The check engine light soon has been on for two to three weeks, I finally got it checked and they said i need my ERG valve cleaned. They quoted it for around 50 bucks, which is fine. However, i dont get paid until a week from now. Will it be alright until then?What are the effects of a dirty/faulty ERG valve if not taken care of??There are not sputtering or anything abnormal that i can tell..Thanks.

- If your truck runs, you can probably continue running it for a while (likely a long while), though you might pollute. If the EGR valve gets stuck open, it will drop your vacuum pressure radically. That will cause your engine to run roughly and inefficiently. If the EGR valve gets stuck closed, your smog system won't work right (you won't be recirculating the exhaust gas to re-burn pollutants. It is possible that the shop had no reason to tell you to clean the EGR valve. You might ask the mechanic if it is stuck open or closed. He might have suggested cleaning the EGR as preventive maintenance.

- Q: right after it come through the foundation. Should it be a gate valve?

- A ball valve for water use. Gate valves fail after a period of time and also leak.

Send your message to us

API Cast Steel Check Valve 150 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords