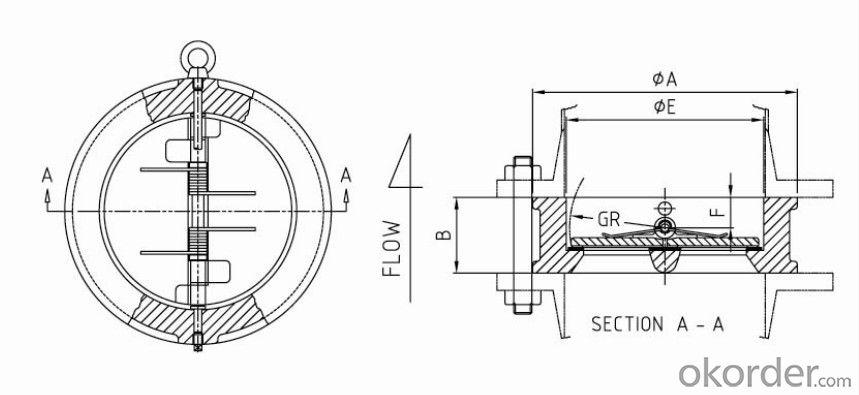

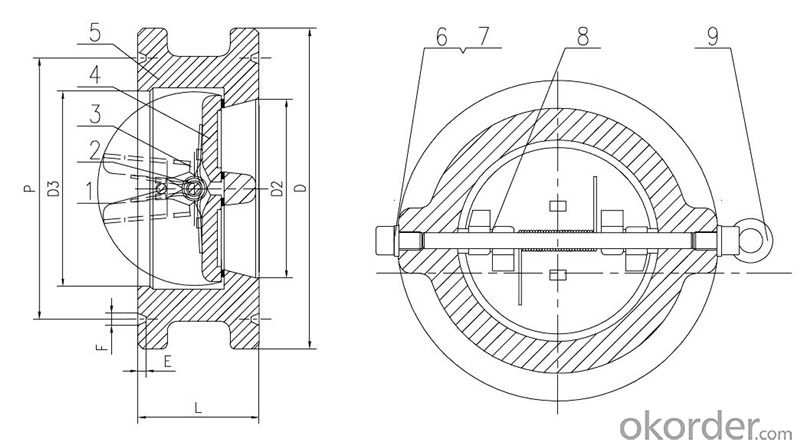

Swing Check Valve Wafer Type Double Disc Body Material WCB

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: what are the best aorta heart valves. mech. or animal.

- Depending on the valve, the original valve may be able to be repaired. This procedure has only been widely used 8-10 years probably. Originally it was believed that these like animal (pig or cow) would probably only last around 10 years but it is constantly being adapted so longer may be possible. Animal valves do not require blood thinners, although many people I know have ended up on thinners because of other problems. The other advantage is that they are quiet. Mechanical valves, often called metal aren't always truly metal. Older valves were thus a scan using an MRI was not possible. Mine was put in during 1995 and is called metal but does not cause any problem with an MRI and I know others from that time frame also with no problem. I expect it to last my whole lifetime and I never needed any anti-reject meds and few people I know have. I do tick like an old watch especially when I get winded or tired, but over the 13 years I've had it only one person outside of medical professionals examining me have ever noticed. It doesn't keep me awake but I do know some people who notice theirs, but the newer the quieter. I do have to take blood thinners, but for me and most of those I know don't have major problems maintaining a therapeutic level. You have to have a blood test routinely to know but they now have a finger prick machine so it is quick and easy. I only know of one person whose body rejected valves and had to have it removed and animal placed in. From those I know usually children they will do tissue just because a child won't be as careful and watchful of bleeding. Otherwise it is choice based on years wanted from the valve and lifestyle if meds fit and eating habits.

- Q: Looking at a few marshall amps and i came across this whole valve amp thing. I've heard about it before, but never really understood it. What types of valves are there?! (i think i've heard of power amp valve) and what type of marshall amps have valves?! Can some of them be part valve and then have that valvestate thing?! :s all pretty damn confussing Cheers

- Marshall were big name in Amps when pretty well everything electronic used valves. Some valves were quite small, some larger, and some are still used today in powerful transmitters. There are those who swear that the sound produced by a valve amplifier is far better than a solid state one. Valve technology takes up much more space than solid state, so miniaturisation is a problem, and also uses much more power and produces a lot of heat. Now solid state is capable of producing high power audio amplifiers which use less power and take up less space, so have become the preferred method. Nevertheless, there is a strong following even today for a good high powered valve amplifier. And yes, it is quite possible to have a valve and solid state mix. The solid state works at the input stage, and the valves take over at high power output levels, but I am not sure what the purists would think about this hybrid usage .

- Q: My electric water heater relief valve keeps opening 30 min after turning it on.I turned it down to 90F and 30 min later overflow again.when power is off no leak with the water on uld the valve be opening because of over heating?I know it does'nt leak with cold running through it.

- the city could have put in a verify valve on the meter to maintain water out of your equipment from backing up for some unknown reason and contaminating the municipal water furnish. whilst the chilly water interior the heater receives heated from fifty 9 to one hundred twenty five levels it expands somewhat. perhaps a cupfull. without place to pass, it opens the relief valve. you would be able to ought to deploy a style tank close to your water heater. that's a metallic tank a pair of gallon in length with a bladder interior packed with air. i don't have one, yet I word a brilliant variety of properties have them now. additionally decrease the drain so which you comprehend it relatively is not plugged or leaking.

- Q: How would your car run if u did not have one on it? Do u really need to have a pcv valve? I have a 1994 Ford Econoline

- PCV valves don't really affect the way a car runs. Unless you leave the hose to it open, creating a massive vacuum leak. They're to keep acidic gases from building up in your crankcase. Without it, you would need to change your oil a lot more often. Before about 1965 or so, cars had what's called a road draft tube, which through a venturi effect, drew out these vapors. Some sort of crankcase ventilation has been used pretty much as long as there have been cars. Many newer vehicles don't actually use a valve, but a calibrated orifice instead.

- Q: ok im buying an aftermarket blow off valve for my car. the car itself is taken apart completely and i have no idea wht vacuum lines go where. i know tht the top nipple of the bov has to be connected to the throttle body but it has 5 lines. does it matter what line is connected to it?

- Don't do it. First of all, if you knew enough about turbo charging or supercharging, blow off valves, bypass values, hooters, etc., then you would have known we need to know the size of engine, model of turbo, piping diameter, etc. The actual control lines are not that complex. By using your tongue you can tell what each line is ported to, and then you just need to know if you blow off valve is operated by vacuum or lack of vacuum. They make both types. And your throttle body will have ports on both sides of the plate. And yes, it does very much matter. Turbo charging is not for the novice to fool around with.

- Q: I have a 3406b motor. It has blow by. This happened when I hired a mechenic to do a top end. I belive that he did not ajust the valves correctly or something happen to the motor. I want to gap the valves to see if this helps out. How would I go on doing this.

- NO, valves does not contribute to blow by in this way.Blow-by is the compression of the cylinder getting past the piston rings during compression. Adjusting the valves is a procedure of the induction and exhaust systems. All engines experience a little blow-by which is supposed to pass through the PCV valve ventilating the crankcase. GOOD-LUCK!! BRILLIANT!!!!

- Q: I have a 4 diameter column of water 10' tall (filled with water). I need to find a flush valve unit to fit into the bottom of it so that it will flush all of the water out of the column in 1 flush. Essentially this will act as a large toilet but it is for a design project at school. My concerns are that the flapper will close before the water is completely flushed out of the column. Is there any way I can make the flapper stay open thus flushing all the water in column out without holding the chain connecting the float to the flapper valve?

- This is an interesting problem. I suggest you study the action of a toilet flush mechanism. Don't have the flapper on the outside, have it on the inside at the bottom of the column, in a small chamber. Use a flapper of very light material, such as a ping-pong ball, which will float on almost no water. (You don't say how fast the column has to drain.) A thought just occured - if the flapper were actually a floating ball, you could pull it up from above, and it would rise to the surface, then follow the water level down, and close it when empty with only a trace of water remaining. I can think of no simpler way to accomplish this challange. Good luck with the project.

- Q: I just fixed a clog in my bathroom sink by taking off the p-trap. I had turned off the water valve beforehand, and when I was done I turned it back on. After this, all that came out of the faucet was a trickle. Turning the valve in the off position does not stop the trickle. When I first turned the valve off before taking off the pipe, the valve was not turned all the way left or right. It was in the middle, but the water flowed fine. When I turned the valve all the way to the right, the water shut off at the faucet. My apartment is pretty old. Is this valve most likely broken?

- Could be a 3-way valve. Try putting it back in the middle. If that doesn't work, it probably broke.

- Q: Is it hereditary? My dad had a bicuspid valve and we got told it was hereditary but some doctors say it's not, my parents wanted to get me tested in case i had it so we would know in advance but the doctors here refuse to do it (I live in England if that makes a difference) my dad said he would pay to go private if it's hereditary. I know someone who had a bicuspid valve and 3 out of her 4 children inherited it, i know it's pretty harmless until i reach an older age but my parents and i would like to know now, i'm 13 by the way.=]

- I am not sure you and your father want to know if this is hereditary. If you have say have a bicuspid valve now it is not going change any thing. You will still have norma life There are many like living normally

- Q: I have several stations in my automatic lawn sprinkler system. Each station has a valve that contains: 1. Manual Shutoff, 2. Flow Control Knob, 3. Solonid, 4. Anti-Siphon valve. Any way my question is this, Why does water continue to flow even when the manual shutoff is turned off and the flow control is also turned off?

- Any manual shutoff should shut the zone down completely, a flow control will limit the volume of water that leaves the valve by resticting the valve diaphram movement. If neither is working they may not be operational. A zone that continually runs either has a plunger stuck in the solenoid, a ruptured diaphram in the valve, or debris between the diaphram and valve body. If all these are contained in the valve, the most likely cause would be a bad diaphram or debris keeping the valve from closing completely

Send your message to us

Swing Check Valve Wafer Type Double Disc Body Material WCB

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords