API Cast Steel Check Valve 900 Class in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

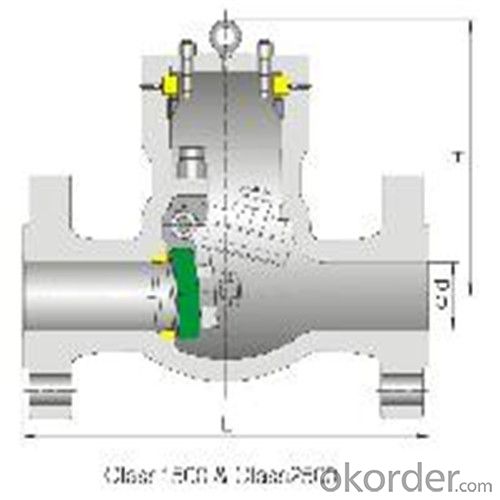

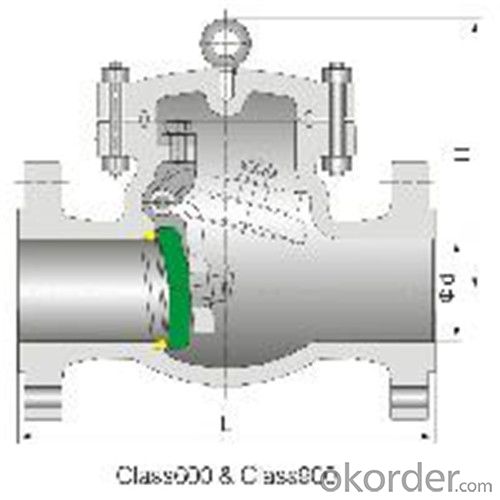

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Surly Pilots don't just switch the fuel selector valve of mid flight

- Most likely it was found in the off position because of impact forces. That's not uncommon. The NTSB report mentions that not only was it in the off position it was torn from the fuselage and the fuel lines to it were ripped off and the whole bottom of the valve body was torn away. The airplane hit the water in a steep angle and at high speed, roughly 1 hour after takeoff. NTSB figured it was in a 45 degree bank and beyond 10 degrees nose down...in excess of 4700 fpm rate of descent. Marks on the propeller plus all the engine controls as well as indications on the gauges indicate that the engine was operating at full power. Last recorded fuel flow an instant before impact was 22 gph. It wouldn't have been able to do that if the valve was off. In the roller coaster ride that the plane went through and the confusion he must have had before hitting the water I'm sure he didn't turn it off...he had all could handle trying to fly the plane. He became disoriented in reduced visibility and who knows what he thought was going on. The destruction was total.

- Q: I just got a new set of tired 2 months ago. The last 3 weeks I've had a separate tire go flat (3 in total). The last 3 the repair company said they were caused by cracked valve stems. So after the 3rd time it happened they replaced all valve stems on each tire. Now today I just got a 4th flat. That's 1 each week for the past 4 weeks. I'm taking into the shop this afternoon for them to inspect the tire. I suspect they will say it's again the valve stem. Any help on what I can do or what to say or ask to get them to fix the problem instead of just putting another bandaid on it? I'm very concerned about my safety and it really sucks that everytime i get into my car, I have to wonder, am i going to get a flat tire today...

- There are only a couple of spots that the tire / wheel assembly is going to leak. Through the valve stem or along the lip where the side of the tire meets the rim. My guess would be that they did not do a good enough job removing debris (corrosion, dirt, etc.) from the rim before they mounted the new tires. With that many flats, you should have them remove the tires and clean the sealing surface. They would prefer not to do this because it means they have to mount and balance the tire again, but it is probably the only way repair the problem. Unless they have a bad batch of valve stems, there is no way that many should fail.

- Q: in engines otto cycle

- All else being equal, larger valves equal less pumping loss and more top end horsepower. The problem with large valves is that at lower engine speeds, the gas velocity is too low to fill the chamber quickly and efficiently thereby compromising low-end torque. The answer to this dilemma is to have multiple small valves. This is the primary reason for current high performance engines being equipped with multiple valves per cylinder.

- Q: school starts tomorrow that means having band and i havent played it in 2 months (summer vacation) and i oiled the valves and the 1 and 2 valves are stuck the 1st valve comes up slowly when i push it down but on the 2nd valve it stays down how do i undo this???? thank you

- You could just get a screwdriver and drill it into the bottom of the valve till it comes out. Its not damaging anything because there are no air pipes going through the bottom .

- Q: I went to the cardiologist yesterday and I was diagnosed with leaky aortic valve. I really want to know more information on it, but i cant find anything. I have two questions:- is aortic valve leakage and aortic valve regurgitation the same thing?- can somebody give me some background information or some articles for me to read so i know how to keep it minor?also heres some family history:My Dad- Arrhythmia, Heart Murmurs, something with Coronary ArtaryMy Mom- Mitral ValveMy (twin) brother- Bicupsive Valve My sister - she has heart papitations, but we dont know what it isim 15 year old girl (if it helps)and right now its not too serious

- 1. okorder /.. that will tell you what to do to keep yourself healthy and help keep te regurgitation mild. Thankfully its just a mild heart problem, so you should be fine for many years. Im 16 and i was born with Aortic Stenosis, and a Bicuspid aortic valve, which led me to develop Aortic Regurgitation(leaky) and an Enlarged aorta. I havent had surgery yet, but my conditions are getting slowly worse and in a few years i will need surgery. I go to a camp for kids with heart disease, and some of my friends have very severe heart problems that cause them to get heart transplants, or tons and tons of surgery and some have even died. :( So if you have any questions or anything feel free to email me(go through my profile)

- Q: instead of just buying a replacement, is there an easy way off the valve to check if it's still good?

- dio, yes, if your sprinkler control valve is not opening a zone valve in the automatic mode, then manually turn the solenoid on the zone valve counterclockwise, it sprinklers come on , then you have confirmed a bad solenoid. these can be purchased seperately or another oprtion is a complete zone valve dio, well, if water is flowing thru then the solenoid is not sealing on the zone valve body itslef. unless there is debris between the solenoid washer and zone valve body, then sounds like a bad solenoid...

- Q: How come my boiler supply valve isnt letting water into my boiler, i have a cold water supply hooked up to it with the valve on i have tested the copper pipe goin into it and water flows into it, but when It reaches the valve it stops. I understand that it my have a backflow preventer in it and I am wondering if that could be malfunctioning. The hole you see on the front is where my expansion tank screws in. Also where could I get a new Valve. Thanks.http://img149.imageshack.us/i/boilerfillvalve.jpg/

- I work on antique steam boilers and engines for a hobby and if your supply valve isn't letting feedwater into the boiler, I'm going to tell you right now that you potentially have a VERY dangerous situation on your hands. Until you get this issue resolved, I would recommend that you not steam this boiler up under any circumstances, unless you have a backup feedwater delivery system that is working correctly. Many people don't know this, but a low water condition in a boiler under steam is essentially a ticking time bomb and can result in a fatal explosion. As to what may be causing it, I would say it's possibly one of two things: 1.) The check valve has been installed backwards and the flow of water is basically pushing it shut. 2.) The check valve is installed correctly, but is frozen shut due to corrosion and scale. Either way, I would have a certified boiler inspector come out and take a look at it; he can probably tell you more than I can.

- Q: i hav no clue wat it is or what it does, but i was goin to buy an 08 mitsubishi lancer but then i read that the valve guides in mitsubishi engines wear out really fast and it causes some problems.what kinds of problems?how will this effect the car?Should i go ahead and buy the car?

- you will burn oil, if you think it may be a bad deal look for something else. plenty of cars out their to choose from. good luck! it will give you poor gas milage, and burn up o2 sensors also.

- Q: How hard would it be to fix an EGR valve on a 1990 Geo Storm that is stuck open? if not fixable, how much would it cost to replace it, or have it replaced by a professional?

- the okorder /.. call the number on this site.. get what you need and have them ship it.. and put it on yourself... save about thirty dollars shop charge.. ok

- Q: my Hunter SVC VALVE will not work with my Lawn Genie Valve. Is this becaous the voltage is not matched? Hunter says it operates solenoids at 6-9 v DC // Lawn Genie says it is an 18 v DC solenoid. :-( my original Hunter Valve broke and I replaced it with the Lawn Genie. Should I get a Hunter Valve , or a Lawn Genie Controller at this point/ or is there something I have overlooked?.

- Your Hunter transformer only provides about half the voltage needed to operate the Lawn Genie solenoid. You might find a weaker spring for the LG solenoid, but the long term fix is to stay consistent. Either use all Lawn Genie, all Hunter, all Rain Bird, etc.

Send your message to us

API Cast Steel Check Valve 900 Class in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords