API Cast Steel Check Valve 700 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

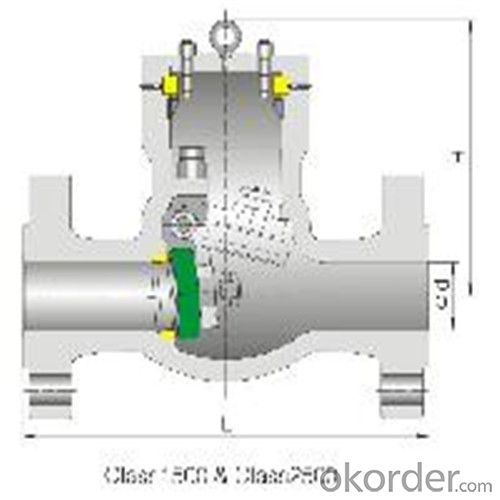

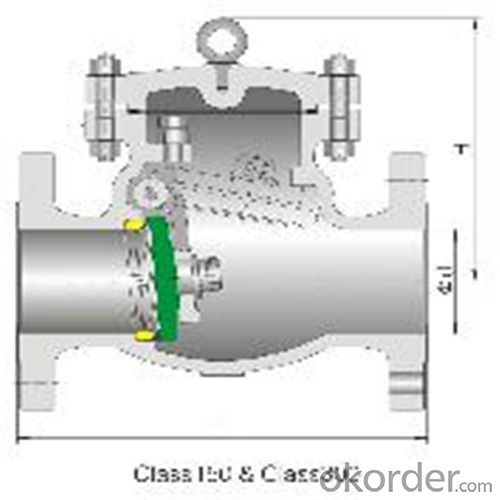

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check="" valves="" and="" welded="" on="" seat="" can="" be="" also="" optional="" if="" being="" requested="" by="" the="" customer.welded="" is="" used="" for="" nps="">12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Does a faulty pcv valve (Positive Crankcase Ventilation valve) cause excessive exhaust smoke ?

- most likely it will knock as well

- Q: I got a 2012 peterbilt 386 ...it just came back from the shop a few day ago to get injectors 4 and 5 looked at and repaired ....I'm getting a fault code for injector spill valve and a engine light ....I tried resetting the computer to get rid of the code but that's not it ... uld timeing of this cause the problem ...but other than that it runs like a champ so what could I do to fix this is it time cause I did probably get re timed when they repaired it

- The fault for the spill valve is not something you can correct with timing. When they repaired or replace injectors they need to be programed into the computer so they match the other injectors. The spill valve is in the injector and is there to return unneeded fuel back to tank. If this valve does not work you could be over fueling or run the risk of fuel cooking in the injector making a mess of the spray pattern. It should be telling you which injector is throwing the code and if it is one of the two that were worked on take it back.

- Q: I live in Houston (where it hardly EVER freezes during the winter..) This winter it froze and the valve on the sprinkler system flew off and water started shooting straight up. Now that it's getting warmer and I'm going to need the sprinkler.. I have to repair it. Is this an easy fix that I can do myself? Or should I call someone.

- If okorder /... If the brass body of the backflow cracked, then you will need to replace the whole thing. That link above has the best prices for these things. Good luck!

- Q: A question about a hot water radiator bleed valve. I read the advise on previous questions and bleed all my radiators except one where the bleed valve broke off when I tried to turn it with the key. My question is that on the other side of the radiator near the floor there is a black knob that turns which I assume should shut off the radiator. If my assumption is correct then I should be able to shut this off and then remove the bleeding valve and replace it without bleeding the system.. Does this sound right? Thanks,.JOE B

- Very easy but quite slow. Open the bleed points on the upstairs radiators and the system will fill evenly. Shut the bleeds when the water reaches them of course. If the pump is accessible loosen the big screw head on the top of it and the will bleed air from the pump. When you think the system is full and the noise of entering water stops then go around to all of the upstairs radiators and check that there is no further trapped air.

- Q: I mean dropping the valve seat. And some mechanic told me that it dropped when the catalytic converter got clogged and it hurt the engine. But the most I've heard is that if I want to avoid this from happening I should be running the engine a bit colder because the valves weren't made with the right specs and after a 100,000 miles they become a bit loose and when the engine gets to the normal temperature or just a bit above, the valve seats would drop. Does ANYONE KNOW ANYTHING ABOUT THIS?

- If the valve has dropped you will hear a ticking nose when the engine is running. It the valve hitting the piston. This need to be fixed ASAP, With a stuck valve you will experance back firing or lots of smoke could out of the tall pipe especially on acceleration. Either way if you are trying to keep your car I would have the problem correctly diagnosed and this will likely means you will need a top end rebuild. These little 1.9L ford engines were pretty tough but after XX amount of miles and so many years it time for some internal engine work.

- Q: I got a cold air intake installed on my vehicle and don't have any AEM bypass valve installed, for preventing hydrolock. If I drill a small hole(e.g 1cm) on the intake(short ram section) can that prevent hydrolock or do I still have to get one of those bypass valves?I'm looking for any alternatives, instead of those AEM bypass valves and was wondering if drilling a small hole in the cold air intake could help in preventing hydrolock, just as good as the AEM bypass valve.

- I okorder (i think thats it) for them, Im pretty sure thats where I saw them. Whatever you do though, dont drill a hole in it.

- Q: I want to change a stuck pcv valve on my 86 toyota pickup 22RE. I've used tons of lube and picked away at the grommet but i still can't get it out. Any advice?

- the grommet is being replaced so do what you have to to get the valve out. id grab a hold with a pair of pliers and go that route.

- Q: this valve used in the refinery.

- This is a 'Trip and Throttle' (T T) valve that is maintained in a 'Fully Open' postion during normal turbine operation. It is maintained open by a Hydraulic Control system that, should any of many shutdown conditions occur, the hydraulic oil will be dumped to its reservoir by the operation of a Solenoid valve, actuated by the shutdown signal, and the T T valve will immediately close, stopping the steam flow to the turbine speed control steam chest in a safe manner. The valve handwheel is then operated to ensure that the valve remains fully closed until the system is ready for re-start. The valve cannot be opened again until the shutdown condition has been rectified and the hydraulic system reset to restore the oil pressure to the valve. The valve however, can then only be re-opened manually and slowly until the turbine is brought to the 'Minimum Speed Control' Governor setting. When settled down at this condition and the steam chest valves are under the control of the Governor, the T T valve is swung wide open. This latches the valve in the fully open position until another shut down occurs,

- Q: what's the function of a car valve???????????

- valve A way to turn on or a off of anything Liquid or gas or air works same as a switch does for power it controls flow of

- Q: This trumpet has been in storage in its casing untouched for about 5 years. I took it out and tried to play it but only air comes out and no sound. The 2nd and 3rd valves are hard to push down. What do I do to fix it? Thanks!

- Dis is a pretty common problem. The valves are in the wrong valve case or they are turned aound in the case. Take each valve out and check the number...... most have a number stamped near the top, or on the part around the spring. Get them in the right place with the notch in the case matching the little peg on the side of the valve and all should be well. By the way, if you can't get a buzz on the mouthpiece the whole problem is you alone.

Send your message to us

API Cast Steel Check Valve 700 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords