Swing Check Valve Wafer Type Double PN 16 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

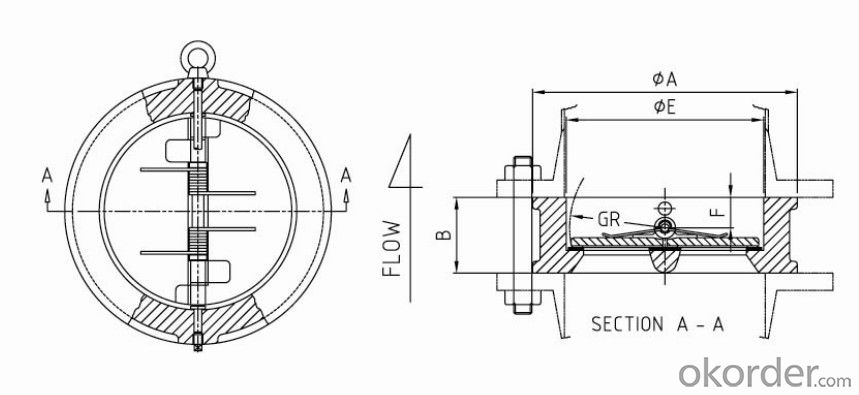

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

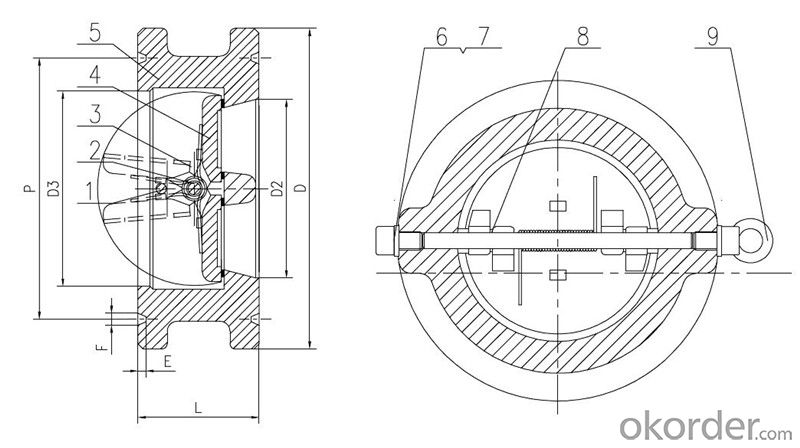

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: whats the location of the pcv valve on on a 2001 bmw 740il (e38)

- In front of the engine slightly to the left and lower area of the throttle valve. It is a round black plastic canister supported by a teardrop shaped rubber with a cable connector at the top and 2 hose connections at the opposite end of the cable connector which are perpendicular to each other. BMW calls it the tank vent valve.

- Q: Why are pig hearts valves used as replacements for damaged heart valves in humans? Are there any complications and are they still used today?

- The tissue is most like ours. Yes, they are still used. They have a low rate of rejection.

- Q: i need to know the setting of the valve and a little advice on the up and down of the valves

- Intake and exhaust valves have different clearances.Which one?To check the clearance- the cam must be in the proper position.Then you take a feeler gauge and measure the distance-you have to do this to each valve before you can remove the cam to make an adjustment.Under the cam lobe-on top of the valve there is a can that rides up against the cam lobe.Between the inside of the can and the top of the valve there is a little round pocket that has a shim that looks like a watch battery.These shims come in different sizes--replacing them with a different size is how you make the adjustment.This is not anything that I would try to do without a manual--things can go bad real quick in the adjustment stage.Not a job for a 1'st timer but you can learn if you watch someone doing it.

- Q: Can sum1 tell me how i can tell if my valves are in the right place?I notice there are holes in the valves, please explain how those holes are suppose to face to for each of the 3 valves?

- Put the correct valve in the valve case. (There is usually a notch that guides the placement, but it is not always accurate enough.) Blow gently into the trumpet, (you don't need to play, just blow as you do to clear the spit valves). If you feel a resistance, rotate the valve until the resistance is gone. When there is no resistance with the valve up, depress the valve and blow again. There should be no resistance there either. Repeat with each valve.

- Q: We have an ejector in the basement for an in-law apartment. When the check valve kicks in, it can wake us up from a sound sleep. A very loud thunking. Any ideas?

- the check valve would be installed just outside of the crock vertically. The noise I doubt is from the check valve itself. I'd guess it is the pump shutting off and the pipe isn't fastened securely, so it bangs. Check to make sure that the run of pipe leaving the crock is fastened securely. if this is the case the only other option I oculd think of would be to re-position the check valve on a horizontal run of pipe as close to the crock as possible. Most check valves I have seen for ejectors are compression type, it will be messy but not to complicated. Keep a bucket handy, when you crack open that check valve you may need it. Flush the toilet until the pump kicks on a few times, this should clear out most of the nasty stuff. You may also need a short piece of 2 pipe and some couplings to make up for the space of the check valve. If you can hear the water flowing out when the pump kicks on and don't hear it draining back into the crock when it shuts off, the check valve is probably still good.

- Q: I want to install a hks blow off valve on my car but is it true that i need a turbo installed first in my car or not.and are they legal in the state of californiapermitted,i want my car to make that air release sound when i shift gears,but it needs a turbo installed or can i still get what i want from a blow off valve without a turbo!!!!!

- If you keep asking this question you may be able to find someone that will tell you that it will work.IT WILL NOT.You have no excess pressure to blow off.No turbo= no boost=no pressure.Record the sound that you want,wire your play-back to a micro switch on the clutch with a P/A speaker under the hood.That's as close as you can get.I'll put it in simpler terms.I T W I L L N O T W O R K.

- Q: A question about a hot water radiator bleed valve. I read the advise on previous questions and bleed all my radiators except one where the bleed valve broke off when I tried to turn it with the key. My question is that on the other side of the radiator near the floor there is a black knob that turns which I assume should shut off the radiator. If my assumption is correct then I should be able to shut this off and then remove the bleeding valve and replace it without bleeding the system.. Does this sound right? Thanks,.JOE B

- You may be able to do this but there are usually two pipes going to the radiator and they may be tied in with a radiator on another floor. Be prepared for some water to come streaming out and do this when there is no hot water in the system. If you have the new valve ready to go with pipe dope or Teflon tape on it you will not get too much water coming out and it will not be under much pressure if you remember to shut off the water supply going to the automatic filler valve at the furnace. Plastic sheets and towels or rags should be in place just in case to catch the water and don't panic or it will take you longer to get the new valve started in the hole. A helper with a thumb to go over the hole to stop the water flow and give you time to do what you need to do may be required so have one of those handy as well.

- Q: Is it hereditary? My dad had a bicuspid valve and we got told it was hereditary but some doctors say it's not, my parents wanted to get me tested in case i had it so we would know in advance but the doctors here refuse to do it (I live in England if that makes a difference) my dad said he would pay to go private if it's hereditary. I know someone who had a bicuspid valve and 3 out of her 4 children inherited it, i know it's pretty harmless until i reach an older age but my parents and i would like to know now, i'm 13 by the way.=]

- it is hereditary sometimes, but sometimes its just a fluke. Im 16 and i have a bicuspid valve and there is no history of this in my family. and yes it will most likely be no problem for you till you get older, if at all most people dont have any problems and will be totally normal, but get it checked just in case because there could be other heart problems caused by it. I have a bicuspid aortic Valve, and aortic stenosis(which is because of the bicuspid valve) which then led to aortic back leak, and then all of those led to be getting an enlarged aorta. Most people do NOT get all these problems, but you never know. Good luck

- Q: here's some additional info asking of my question...I plan on buy a BLOWOFF VALVE and woundering where does the BLOWOFF VALVE goes in my car or do i have to replace with stock EGR VALVE using same hoses or help me please don't wanna screw this one up

- Ben- If your car is not turbocharged you cannot install a blow-off valve. If your car is turbo-charged, this annoying device replaces the Waste Gate. What does a blow-off valve do for your car? NOTHING! It does not add horsepower. It is simply a noise maker to attract the attention of Law Enforcement. So what can you install to improve a Turbo-Charger's boost capability? HKS Controller, Cold Air Intake, Intercooler, High Flow Catalytic Converter, and some type of high performance exhaust system. What's this going to cost? $5000.00+ easy! Lastly, the Blow-Off Valve has nothing to do with the EGR Valve. Two totally different devices, performing two completely different tasks. And... not to burst your bubble. Since you don't know the difference between a Blow-Off Valve and an EGR Valve, I suggest you start taking some basic Automotive Technology classes BEFORE you get into learning about the high performance parts. Why? The last thing you want to do is get into something that is over your head, then have a very large repair bill on your hands because your inexperience in the task at hand is the result of the damage done to your car. One last item here. Performance does not equal fuel efficiency. The more horsepower you want, the more fuel will be required to make it. The more horsepower you desire, the lower the reliability. This becomes a factor because you will be harder on the parts which are doing the jobs required of them. So think before you decide to make major changes to your daily driver. Making performance changes to your daily driver, is a great way to have your friends passing you up with you stuck on the side of the road facing a big tow bill and an even larger repair bill. Bottom line, build your muscle car for a weekend romp, and leave the 4 Cylinder job shuttle alone. Just speaking from 25+ years of turning wrenches!

- Q: im wondering if valve is working on portal 3

- What Valve has made Half Life 1 2 Portal 1 2 Team Fortress 1 2 Left 4 Dead 1 2 What Valve has not made Half Life 3 Portal 3 Team Fortress 3 Left 4 Dead 3 Seems Valve has a problem with making trilogies :'(

Send your message to us

Swing Check Valve Wafer Type Double PN 16 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords