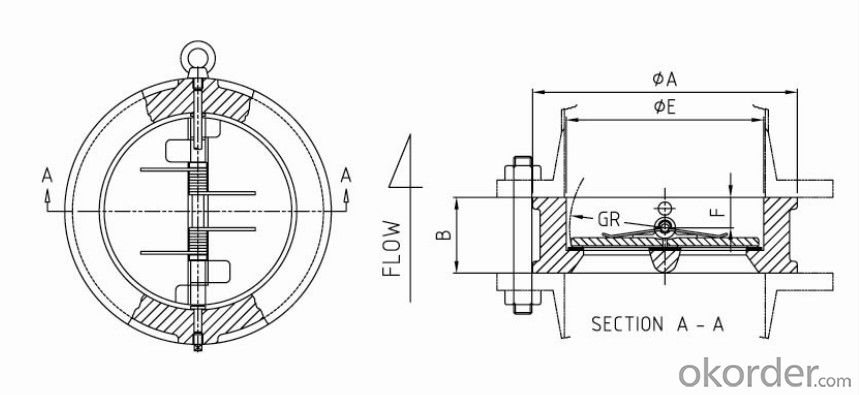

Swing Check Valve Wafer Type Double Disc PN 1.6 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

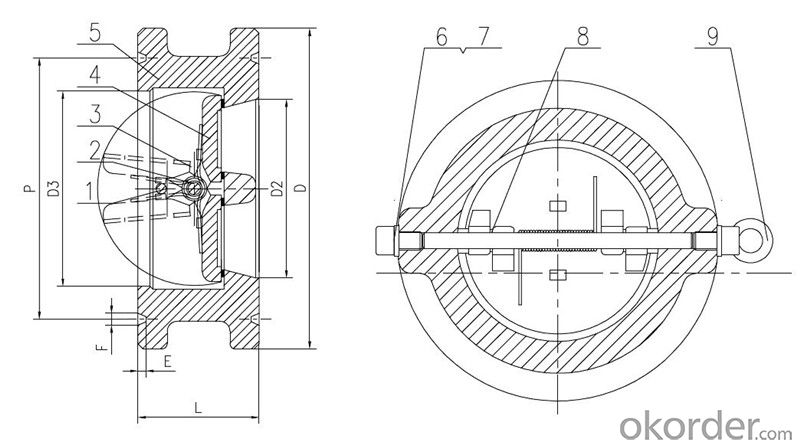

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: after my hot water tank shuts off about 1/4 cup of water comes out therelief valve. i changed the relief valve. the tank is 6 months old

- My okorder /

- Q: I am buying a 2004 Ford Taurus tomorrow and want to know the difference between a 24 valve V-6, and 12 valve V-6...Now besides the obvious difference in the # of valves...Is one better then the other???

- The 24 Valves were marked with DOHC on the Engine and on the outside of the car.

- Q: Mostly suction apparatus with dual head motor, consist a non-return valve, what is its function to have it on the apparatus and not to have it?

- Non return helps to prevent flow back of the material needed for trasportation,also helps to prevent material to be lost when the motor is turned off,ensures maximam flow. Not to have reason all liquid intedend for transportation will flow back when motor is turned off,difficult to ressit materiall in vertical direction.

- Q: I want to install a hks blow off valve on my car but is it true that i need a turbo installed first in my car or not.and are they legal in the state of californiapermitted,i want my car to make that air release sound when i shift gears,but it needs a turbo installed or can i still get what i want from a blow off valve without a turbo!!!!!

- teh valve is designed for use with a turbo to prevent over boost destroying things! hence we do need a turbo. vary rare to be worth fitting to a car eg installing a turbo. much better to exchange for a car with a turbo as standard ( also insurance etc is easier to sort) the gas pressure relief valve only sounds nice to boy racers. everybody else thinks it very geeky.

- Q: Where is the illusive heater control valve?

- The only valve i could think you are referring too would be the vacuum control on the back of the dash mounted heater controls. They do not have a valve in the coolant lines. The heat turned on or off by a vacuum operated door inside the heater box that merely closes and blocks the heat from escaping into the car. If you are having heater problems first make sure both lines running to the firewall feel hot/warm when engine is at temperature. Secondly you will have to find the actuators under dash on the heater box and make sure they are moving if not ck for vacuum.......

- Q: i was told my egr valve needs to be replaced, so im wondering if the system cleaner will help at all. thanx

- With an egr valve it's the diaphragm leaking,additives will not help that

- Q: my valves are making a taping sound and i lost a lot of power and need to know will lose valves make me lose power so can someone tell me what they are seat on thanks

- 04 Suzuki Ltz 400

- Q: Hi.. I was looking forward to install an electric supercharger for my 2 litre non turbo engine.This unit is driven by an electric motor instead of being mechanically driven.My question is if I can install a blow off valve in between the supercharger and the inlet manifold? Will it work?

- You don't need a blow off valve. They create only 2lbs of boost which will not get your intake out of vacume, let alone produce pressure. The main efect they have is they mix the air and fuel better for better combustion. Weisco did make a prototype that produced 8 psi though!!! Can't wait for that one.

- Q: Are they referring to the nozzle orifice or are they talking about the diameter of the nozzle? Does it mean the inner diameter of the valve like in a globe valve?

- A 12 inch valve means it is designed to fit with nominal 12 inch pipe. Most 12 valves are flanged so these valves would also be flanged to match as 12 piping flange. They would also be sized to match the appropriate flange rating as in 125#, 250#, 150#, 300# 600# and so on. As to the opening of the valve that will vary depending on the type of valve. For a gate valve it will be very close to 12 inch in diameter. For a globe valve it may be a bit smaller. In some cases you will see what it called a reduced port valve where in internal opening is smaller. This is more common with large ball valve where the smaller ball and opening makes the opening/closing torque less. These valves also tend to have a venturi shape on the inlet and out leading to be ball so the pressure drop is closer to a full opening valve.

- Q: I don't know the principle of operation of the butterfly valve. Can I control the percentage of opening by an analog output from the PLC?

- A butterfly valve does not have an overall linear characteristic and is a poor modulation controller through its full range of operation. It will need a stout shaft and a tough actuator. It will be most linear in about the 30% to 60% open range. To make a full linear controller, you will need to have the actuator-controller- valve , single source supplier know what control feature you wish to accomplish in the fluid system and what the controlling signal will be. Any cotrol valve is a variable resistance added in the whole dynamic system which itself will have an inherent second order friction loss flow characteristic.

Send your message to us

Swing Check Valve Wafer Type Double Disc PN 1.6 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords