J41F-16 fluorine plastic shut-off valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

J41F-16fluorine plastic shut-off valve descriptions

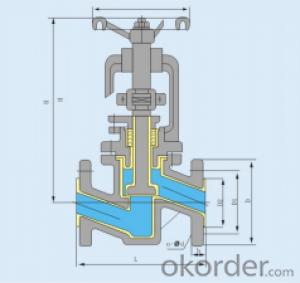

J41F-16fluorine plastic shut-off valve, valve body made of carbon steel casting, valve rod and flow components are using steel skeleton outsourcing fluorine plastic, design for control the opening and closing of all kinds of strong corrosive medium, has strong corrosion resistance, high pressure resistance, high reliability, widely used in conveying all kinds of strong corrosive medium pipeline.

Applicable temperature:-20℃~120℃

Nominal diameter:(DN)25-150mm

Nominal pressure:(PN)1.6MPa

Testing experiment medium: Acids,bases,salts,solvents

2. Model sense

EX: J41F-16-100

- J: Globe ball valve code

- 4: Connection Type is flange

- 1: Structure type is floating straight-through

- F: Flow parts are fluorine plastic

-16: Nominal pressure 1.6MPa

-100: Nominal diameter is 100mm

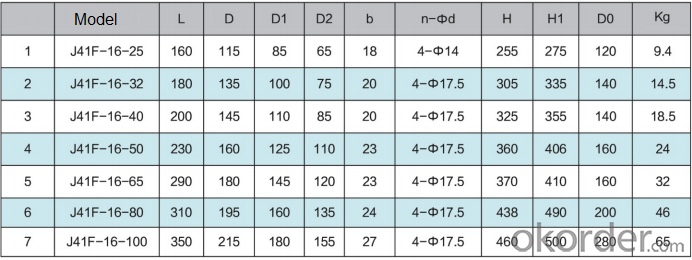

3. Model and path

4. Features

1. Compact structure, flexible opening and closing, strong corrosion resistance, short travel distance (usually 1/4 nominal diameter) and so on.

2. Disc and stem design as one structure, to prevent the pressure fluctuation of the pipeline caused by the inner parts out of the valve body may be, compact structure, safe use.

- Q: What is it for? I was given a data set which is a result of antisurge valves testing every 2 seconds or so. (more than 1000 rows, measurements by time) I have no idea how to start analysis of the data like that. Can anyone help?

- An anti-surge valve is a valve that automatically opens to produce a flow through a centrifugal compressor to prevent surging of the compressor at a low flow rate. At surge conditions, there is no forward flow in the compressor and the compressor shaft will move foreword and backwards against the thrust bearing. This is damaging to the compressor and causes a terrible noise, that once you hear a surging compressor, you will never forget it. On an air compressor, the surge control valve will discharge to the air through a muffler. For process gas, it will discharge to another part of the process. The answer to your question depends on whether the data relates to the flow through the anti-surge valve of the compressor. It could even be a record of how fast the surge control valve operates. Based on this, no one can give you an answer for certain. TexMav

- Q: I own a 2001 Chevy cavalier Z24 with a dual cam... Just got it tuned up and noticed oil in my spark plug sockets, which leaves me to assume either the valve cover gaskets or the cam carrier gasket is leaking oil... I would prefer to so this by myself considering I'm sure it's going to be costly.. Anyone have any ideas on how I go about replacing either?

- valve cover shouldn't be that much of a problem as long as you have some basic tools and some mechanical ability. Take it that its a 4 cylinder car, the size of the motor is very helpful when looking for tips. Just don't over torque your bolts when replacing. 89 in lbs is about normal on gm's valve covers

- Q: what are the factors should be know to select a control valve for specified application

- nan

- Q: It's just a small 1 cylinder 1000 watt generator but thanks to contributors here, I verified the exhaust valve is pitted after I cleaned it all up with oven cleaner a toothbrush. My question is can I just replace the valve itself or do I need an entire new head? The seats still feel smooth.

- There is no need to replace head if the seat is good. Blue smoke indicates to rich a fuel mixture,white indicates oil consumption.

- Q: I have a 3-circuit sprinkler system in my yard (built by me, last year). I discovered this week that I overtightened the connection between the valves and the downstream pipes, and 2 of the three valves are cracked, and leaking, at the connection. I replaced all 3 valves, and now I need to reconnect them to the supply. But this means I'm working backward - when I bult the system last year, I worked downstream - I built the manifold first, connected the valves, then the remainder of each branch. Now, I have to make the new manifold fit the valves, and naturally, they don't line up perfectly. Any tips/tricks on connecting valves in this situation? Is there such a thing as flexible pipe that can withstand continuous pressure? I'm using unions at both ends of each valve to help things go together/come apart more easily.

- valve manifolds are something that requires practice and experience. i used to struggle with them at work until i did a good bit of them. 3 zones is not that many valves so it shouldnt be too difficult. if they wont line up exactly right, i would recommend adding longer peices of pipe to the mainline side of the vavles and re routing the supply line futher back and you will have more room to flex the pipe and vavles into the Tees and 90s. do not use any form of flexible pipe on any mainline. you will regret it. lol the bigger the hole you dig will give you the most room and the more pipe, and room will give you more flexability to build the manifold. it is easier to connect the valves the way you did it first though, but you can do it either way. good luck and hope this helps

- Q: Ok, so I was just wondering, do you have to have a turbo to get blow-off valves? Also, do you have to have a manual? And are there any other requirements?

- I'm a girl.....you don't have to have a turbo, any type of fast car will get you blown off.

- Q: i wanna know the role of TOP ENTRY in this definition it's difference with side entry valve.

- The ball and seat components enter from the top for top entry ball valves, while the ball and seats enter from the side for side entry ball valves. The top entry features online maintenance without dismounting the valves from the pipes.

- Q: I heard there are really fine valves, does someone possesses thoughts where to buy these goods? I heard about them on TV. Anybody alive?

- Any plumbing supply shop should have them as well as most home stores, but they are generally for a specific purpose such as at the bottom of a well pick up pipe. Basically a check valve to prevent water from draining back to the well when the pump is off, thus eliminating the need to prime the pump for every on cycle. Al

- Q: Well I had a Anginogram that said I have Mitral Valve Stenosis with the LVEDP was Moderately Elevated and My Right Ventricular Moderately Elevated and My Right Atruim is Moderately Elevated what do all this mean I see my cardiologists in two weeks to go over things. Oh yes they don't say how much the Mitral Valve is narrow.

- Mitral stenosis (MS) is narrowing of the mitral orifice impeding blood flow from the left atrium to the left ventricle. The (almost) invariable cause is rheumatic fever. Common complications are pulmonary hypertension, atrial fibrillation, and thromboembolism. Symptoms are those of heart failure; signs include an opening snap and a diastolic murmur. Diagnosis is by physical examination and echocardiography. Prognosis is good. Medical treatment includes diuretics, β-blockers or rate-limiting Ca channel blockers, and anticoagulants; effective treatment for more severe disease consists of balloon valvotomy, surgical commissurotomy, or valve replacement. The normal area of the mitral valve orifice is about 4 to 6 cm2. Under normal conditions, a normal mitral valve will not impede the flow of blood from the left atrium to the left ventricle during (ventricular) diastole, and the pressures in the left atrium and the left ventricle during diastole will be equal. The result is that the left ventricle gets filled with blood during early diastole, with only a small portion of extra blood contributed by contraction of the left atrium (the atrial kick) during late ventricular diastole. Patients with mitral stenosis prompts a series of hemodynamic changes that frequently cause deterioration of the patient's clinical status. A reduction in cardiac output, associated with acceleration of heart rate and shortening of the diastolic time, frequently leads to congestive heart failure. In addition, when AF sets in, systemic embolization becomes a real danger. Please undergo echocardiography test and check whether you have other heart defects such as mitral regurgitation and aortic insufficiency.

- Q: My car (RWD) has vacuum leak and has the code PO171/PO174. I find some engine oil at the bolt well of the valve cover on the bank 2 side. Can the vacuum leak come from the valve cover? What is the main function of the valve cover? Thanks.

- there is no vacuum in the valve cover. the vacuum is in the intake the valve cover is leaking oil. the valve cover covers the rocker arms.

Send your message to us

J41F-16 fluorine plastic shut-off valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords