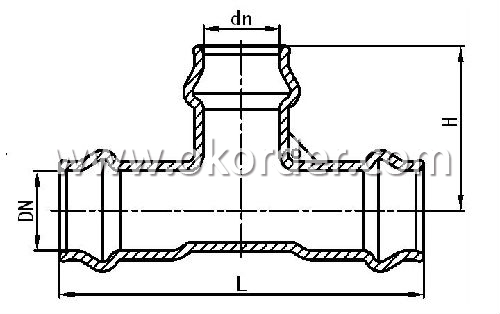

ISO2531 All Socket Tee Of Manufacturer From China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000Pcs/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of ISO2531 All Socket Tee Of Manufacturer From China

1. Sureface treatment: epoxy painting or according to the customer's request

2. Standard: ISO2531 EN545,EN598,BS4772

3. Size: 80-2000

4. Inspection: SGS inspection

5. Pressure: PN10,PN16,PN25

6. Material: ductile iron GGG507,ductile iron 450-10,450-12

7. Delivery Time: 20-30days or as per clients' request

8. Sureface treatment: Zinc plus Bitumen external+Cement Mortar internal

9. Accesories: Gaskets,bolts and nuts.

10. Rubber Gasket Material: EPDM, NBR, NBR

11. Mechanical Properties: Tensile Strengh: ≥420 MPA; Elongation: ≥5%; Hardness: ≤250HB; Yield strength: ≥300 MPA

12. Hydrostatic Test Pressure: DN 80mm-DN 300 mm: 25 bar; DN 350-DN 600 mm:16 bar

Applications of ISO2531 All Socket Tee Of Manufacturer From China

1. For industry fields use,such as petroleum, power, papermaking, chemical, aviation, boiler heat, exchanger fields.

2. For electric, shipbuilding, construction fileds

3. For the foodstuff,medical equipment, and other fields

Packaging & Delivery of ISO2531 All Socket Tee Of Manufacturer From China

Packaging Detail: wooden cases with plastic layer, wooden pallets with plastic layer, steel crates. Or as per customer's requirements.

Delivery Detail: according to your order.

Quality Control of ISO2531 All Socket Tee Of Manufacturer From China

Our team concentrates on quality management, technique improvement and innovation, by regarding quality as the first and foremost factor in our organization development. Quality control is arranged through all stages of manufacture. We have good quality control system, great production capacity and perfect quality stability.

- Q: im from scotland and the speed limits are 30 in towns and citys and 70 on the motorway and sometimes a 20 if theres speed bumpsso whats the limits in the usa?

- No. I live 3rd class in Philadelphia. I am barely able to afford food at the moment. Do you really expect me to help you pay something for Tiger Woods that he can already afford?

- Q: I just moved to a new house (less than 2 years old). The contractor who lived in it put in a central smoke alarm system. Each room has its own smoke alarm and when one goes off, they all go off. Problem is, one always chirps (in the upstairs bedroom). It started to be once a month. We would hit the reset button, ALL of them would squeal for 30 seconds, and all would be fine. Then the same one would start chirping every week. NOW it's every 3 days!Does this matter? We live in a two story home. We live on the first floor and don't purposefully heat the upstairs. (Extra bedrooms that we don't need at this time.) The smoke alarm that goes off is in the upstairs bedroom (unused).At first I thought it was carbon monoxide and I put a detector in there but it still reads zero. It seems like they are plugged in and not battery operated. Well, we can't figure how to get the covers off of them. Who should I call? An electrician? I don't know the brand of alarm system.

- He and his father planned to build a boat during the summer, but it never happened. Boo's good deeds include wrapping Scout with a blanket the night when Mrs. Maudie's house caught on fire. Boo also helps save the lives of Jen and Scout by preventing Bob Ewell from killing them.

- Q: I'm looking for a good bait casting rod. I was thinking about either the Berkley Amp or the Berkley Lighting rod shock. If you want to introduce me into new rods they have to be in a price range of $20-$50. Also if you find one it has to be at Cabela's or Bass Pro Shops. Thanks.

- Pipe fittings screw 3/4 pipe into the exhaust port about 7 then pit a pipe fitting that makes 3 /4 1.5 and add about 12 of 1.5 on that motor that will lower the exhaust note. You might have to put on a 90 degree before that heavy mess to make the pipe come out in the right place.

- Q: What do you mean by pipe joint 3/4-150?

- The pipe joint diameter is 3/4 and the length is 150MM

- Q: An accidential fire alarm was triggered at work and when I got out of the building I placed a call to 911. (Like the sign on the outside of the building says) 911 says its a false alarm bt they have to send the fd anyways. I tell my boss and when get back from lunch he says I'm being officially repromanded bcuse the fire department had to do an inspection that closed the building down for about 45 minutes. He stated that the floor marshal decides if the fire department or 911 needs to know.Can they actually legally repromand me?Can

- u need a 1 1/2 to 1 1/4 '' reducer

- Q: I drive a '91 Nissan Stanza, manual transmission, and we've never really driven it in the winter since it's been sort of a back up car, but since I turned 17, I finally am granted the privilege of having my own! The problem is, winter is coming up in Colorado, and I'm afraid it won't be able to make itthere's a steep hill right at my school in the mornings, and sometimes it may ice upand driving a manual in that situation sucks..am I going to be okay?Also, my second question is, every summer, I go up to the mountains, and there is a dirt road that's considerably steep and bumpy for about 3-4 miles, and I was wondering if this car could make it? I haven't souped it up at all..it's pretty much just in good conditionthx all

- if its not on your property then no, you will have to get permission first. at my old house we had the hydrant ON our lawn and still got a warning when we painted it because its not technically our property

- Q: SuRvEy:: - ::> How many Aardvarks does it take to make a really good speed bump?

- Your fairly must begin through ruling out this being a UTI. Has he simply began this or has he in no way been in a position to maintain for the complete night time? Does he pee plenty in the course of the daylight hours? And for that topic, is he ingesting excessively? Collect a pattern of his urine and take it, with him, on your vet. Once you have got been in a position to rule out this being a clinical concern, or received it handled, then I'd endorse you have to stand up in the course of the night time to allow him out to drain. Bit of a bind, however no less than that are meant to quit his have to pee interior. Getting rid of him should not be an alternative. Most condominium-coaching can also be taken care of out, with slightly 'adjustment'. And might you be pleased approximately sending him off for anyone else to style out after all? Also wherein does he sleep. Sometimes puppy will do that style of factor as a protest! It could support, if he sleeps in a different field at night time, when you take a look at bringing him in with you in a single day, in a crate. I nonetheless suppose you have to take him out once or more in the course of the night time, to start with, but when he is happier, confidently he's going to sleep proper via with out all this happening.

- Q: Hi!Before I begin, please don't answer if you are going to lecture me about spurs. I do respect your opinions, but that is not what I need right now. Alright, I was wondering what your favorite spurs are. Right now, I have regular metal ones, they look like this:

- You should probably either A. Go straight to the police and tell them everything or B. tell your parents and see what they can do. I know it seems like u shouldn't but maybe this time you should. I think he can get in REALLY BIG TROUBLE for doing it with a girl younger then him and recording it. Hope this helps ^-^

- Q: I personally think all 3 previous shield members brings something differentRoman is the look. He's a big guy with tattoos, long hair and he automatically resembles the ultimate wrestler. But I think he's a bit overrated. Not that I don't like him but still, There are others way better in the Powerhouse area, Like CesaroSeth has athletic capability and very impressive Ring work. I don't like his character though but it's just a story.As for Dean. He's my Favorite. He reminds me of the Attitude era. He's not afraid to put his body on the line and he's very unpredictable. His mic skills are great and the fans love him but I feel like he's not completely there yet??What do you think. And who do you think will hold the WWE World heavyweight belt first. I think Seth since he won the Money in the bank contact

- straightners are best,, i bought a curling wand last year and it took so long to do and it only came out sort of wavy and lasted only a few hours,, so i tried using my straightners and it was quicker and the look lasted longer and had bigger curls,, if you dont know how to use straightners for curling there are loads of tutorials on youtube.

- Q: how long do you think it would take a mechanic to tighten the wheel studs on my 93 integra. the guy i bought it from said that i had to tighten the wheel studs on it as he had just put a new tire on and the wheel was making noise because of the loose studs. i have an extra set of studs in case i need new ones, and also how much do you think it would cost for him to do it?

- if this is a water line u must shut the water off to the home. take a torch and heat the damaged area. take some flux( its a solder paste) and brush it over the area. then take some solder and add to the area. do this while u have the torch heating the pipe. it will not work without the heat if u never did this before u may be better off contacting a plumber. good luck

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 13 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications | ISO 9001:2008; ISO2531:1998 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Dalian, Tianjin |

| Export Percentage | 52% |

| No.of Employees in Trade Department | 500 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 6500 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

ISO2531 All Socket Tee Of Manufacturer From China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000Pcs/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords