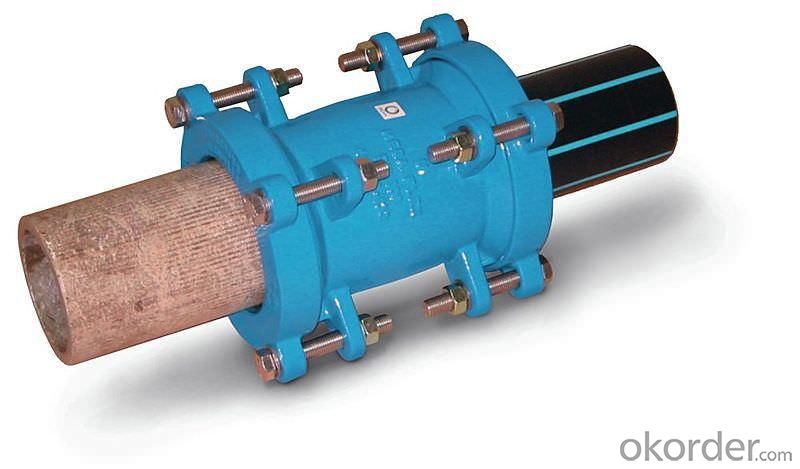

Flexible Coupling

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 PCS pc

- Supply Capability:

- 1000 Ton Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Specifications of Wide Range Flexible Coupling

Material body: Ductile Iron grade 500-7/450-10 in accordance with ISO1083 or 70-50-05/65-45-12 with ASTM A536.

Gland: Ductile Iron grade 500-7/450-10 in accordance with ISO1083 or 70-50-05/65-45-12 with ASTM A536.

Gasket: Rubber EPDM/SBR/NR in accordance with EN681.1

Bolts and Nuts: Carbon Steel grade 8.8/6.8/4.8 with dacromet coating/galvanization.

Features: Wide joint range, suitable for the joint of DI/PE/PVC/STEEL pipe; Vibration absorption, end movements and angular deflection +/-8 degree.

Pressure Rating: PN10/PN16

SIZES | RANGE | U.WGT | BOLT SIZE | BOLT |

DN40 | 48-60 | 2.86 | M12 X 175 | 2 |

DN50 | 59-72 | 3.11 | M12 X 175 | 2 |

DN65 | 72-85 | 3.60 | M12 X 175 | 3 |

DN80 | 88-103 | 4.22 | M12 X 175 | 4 |

DN100 | 105-122 | 4.80 | M12 X 175 | 4 |

DN100 | 109-128 | 5.05 | M12 X 175 | 4 |

DN125 | 125-140 | 5.50 | M12 X 175 | 4 |

DN125 | 132-146 | 5.91 | M12 X 175 | 4 |

DN125 | 138-153 | 5.76 | M12 X 175 | 4 |

DN150 | 155-175 | 7.50 | M12 X 175 | 4 |

DN150 | 159-182 | 7.70 | M12 X 200 | 4 |

DN175 | 192-210 | 9.20 | M12 X 200 | 4 |

DN200 | 218-235 | 9.95 | M12 X 220 | 4 |

DN225 | 230-247 | 14.35 | M12 X 220 | 5 |

DN225 | 250-267 | 14.50 | M12 X 220 | 5 |

DN250 | 265-280 | 15.00 | M12 X 220 | 6 |

DN250 | 272-289 | 16.50 | M12 X 220 | 6 |

DN300 | 315-332 | 23.50 | M12 X 220 | 8 |

DN300 | 322-339 | 23.80 | M12 X 220 | 8 |

DN300 | 332-349 | 24.00 | M12 X 220 | 8 |

DN350 | 340-360 | 35.00 | M14 X 240 | 8 |

DN350 | 351-368 | 35.00 | M14 X 240 | 8 |

DN350 | 374-391 | 35.00 | M14 X 240 | 8 |

DN400 | 394-412 | 40.00 | M14 X 240 | 8 |

DN400 | 400-429 | 40.00 | M14 X 240 | 8 |

DN400 | 410-436 | 40.00 | M14 X 240 | 8 |

DN400 | 425-442 | 40.00 | M14 X 240 | 8 |

DN450 | 455-472 | 43.00 | M14 X 240 | 8 |

DN450 | 476-493 | 43.00 | M14 X 240 | 8 |

DN450 | 480-500 | 45.00 | M14 X 240 | 10 |

DN500 | 500-535 | 53.00 | M14 X 240 | 10 |

DN500 | 526-546 | 53.00 | M14 X 240 | 10 |

DN500 | 555-572 | 53.00 | M14 X 240 | 8 |

DN600 | 566-583 | 53.00 | M14 X 240 | 8 |

DN600 | 582-599 | 53.00 | M14 X 240 | 8 |

DN600 | 600-635 | 66.00 | M14 X 240 | 10 |

DN600 | 630-650 | 66.00 | M14 X 240 | 10 |

DN600 | 645-662 | 70.00 | M14 X 240 | 10 |

DN600 | 662-679 | 70.00 | M14 X 240 | 10 |

DN700 | 692-712 | 75.00 | M14 X 240 | 10 |

Application Introduction of Wide Range Flexible Coupling

The Universal Couplings are designed for pipelines as a wide tolerance system. it will fit most standard pipe materials and therefore dramatically reduces the number of dedicated Couplings,which need to be stocked for maintenance purposes. It is suitable for steel, GRP, PVC, PE, Ductile Iron, Cast Iron and Asbestors Cement. When connecting PE pipes, It is important that pipe inserts are fitted to the PE pipes.

Packing & Delivery of Wide Range Flexible Coupling

Packing: Wood crates/Wood pallets/As per customers' requirements

Delivery: By Container or bulk.

Production Flow & Inspection of Wide Range Flexible Coupling

*Automatics machine lines*

*Resin Sand*

*Molding Boards*

*Green Sand with hand molding*

*Foundry in-house*

Ps: Third Party Inspection is also available upon request. More information is available upon receipt of your enquiry.

Process & Installation Instructions of Wide Range Flexible Coupling

1. Examine the pipe ends and ensure they are round, smooth, free from buldges, dents and score marks and within the outside diameter range given on the adaptor label. Weld beads must be ground flush maintaining correct surface profile. Ensure that pipe ends are free from scale rust or any loose debris or other surface defect that may affect coupling performance.

2. Check grade of gasket is suitable for the conveyed medium.

3. Align pipe to be laid with pipe already in position, taking care that pipe ends are concentric, adjusting support or trench bed as necessary.

4. To aid installation, mark both pipe ends at a distance equal to or greater than half the overall coupling assembled width of the coupling. Place wholly on one pipe end.

5. Adjust setting gap between pipe ends as necessary.

6. Using marks made at step 4, slide the coupling to a central position over the pipe ends and commence bolt-up.

7. Tighten diametrically opposed bolts giving the nuts one or two turns at a time to draw up the end rings evenly. The bolts must be thoroughly tightened to the figures given below, working around the coupling as many times as necessary. On completion, the radial gap between pipe end coupling should be even all the way round rubber may be seen to extrude into the gap.

- Q: Quick plug and card sleeve joint sealing which good?

- 1, small;2, standard type;3, metal type;4, stainless steel type;5, flame retardant;6, compound type;7 drum type joint body combination;

- Q: Right, me and my bf went for a walk and i text my friend and then left my phone on a wall. right next to the wall were gardens, 4 kids were on a trampoline staring at us. when i got home i realised i had forgotten my phone. i ran back to the spot and it was gone, but the children weren't in the garden. we rang it over and over, once someone answered made a screaching sound and hung up the phone. we then went to knock on their door and ask if they had seen it, they said no. now i still dont have my phone, is there anyway i can track it? where i last had it wasnt far away. it has now died, so when we ring it, it goes straight to voicemail. HELP?!?!

- judging from the name of the hand shake i am guessing its a very rough handshake that breaks your bones? lol

- Q: I don't believe in ghosts. Wierd things have always happened at my house but ignore it. But for months my bedroom door locks itself when I am in my room. Or when my husband is alone aleep. Its epecially happenda when we sleep.Today my husband went in and the door locked on its own i knocked n before he opened it. It unlocked on its own. If this is a ghost is it a bad one?

- You have an older home if it is a 2 wire outlet. The only way to fix the problem is to replace the outlet with a GFI Outlet. DO NOT!!! REPEAT DO NOT run a ground to the cold water pipe, because this will give you a dual grounding path. Which in turn, during surges could very possibly blow up your new TV, because of the type of load that a television is. Good luck

- Q: Surely there is a lot of infrared light (black body and other) around at all times, how does the sensor differentiate this ambient light from the remote signal? Also, how is it that I don't need to point my remote directly at the sensor, I can have the remote in a bookshelf pointed away from the sensor and the remote still works. Are most materials highly reflective at these wavelengths?

- i have had several root canals and not a bit of pain it is not any worse than getting a filling. They give you Novocain and drill a small hole to the root. Once they drill through the root, all pain (previous to the dentist visit) and discomfort will be gone.

- Q: How to distinguish between flared pipe joint and welded pipe joint

- Welded pipe joints: welded pipe joint applicable medium: oil, water, gas and other non corrosive or corrosive medium. The welding type sealing pipe joint with steel pipe specifications and flexible pipe welding, has the characteristics of reliable connection, good sealing performance, so it is widely used in oil refining and chemical engineering light industry, textile, metallurgy, aviation, defense, and ship system; also suitable for hydraulic transmission of various mechanical engineering, machine tools and other equipment pipeline. When the sleeve type pipe joint production can not meet the needs, and in the case of strong corrosion, priority can be adopted.

- Q: Now that NBC fired that liar Brian Williams, should FOX follow suit and fire its entire lying broadcast staff?

- I have a suggestion but first let me shoot down some of the other idea's with the fact that in cold weather you ALWAYS need access to pipes and fittings. Heat tape-no, the electrical in heat tape goes bad and you will have no easy way to repair. Crawlspace- even if heated, you said there will be no access Ceiling running down- no, there is no heat in the ceiling and the lines would need to be exposed in the bathroom. Cold air return-maybe but again, no access I'm assuming this schoolhouse has a basement, most do, and your best option would be to build a secondary partition wall on the same wall as the addition to hide the plumbing and run it into from the basement. Essentially just poking through the now exterior wall and the new addition wall from inside the new fake exterior wall . It sounds like you need a H C for the washer, a H C for a vanity sink and a C for the toilet? Obviously the best thing would be to make as few penetrations as possible so use 3/4 copper for the sink, run flex hose or tubing for toilet and run two exposed lines from the vanity THROUGH(vanity) the side onto the wall(exposed) for the washer. I'm kind of guessing here as I'm not able to see the layout. If you're willing to make 4 penetrationsgo for it. The toilet only needs to be hose or tubing, make sure you put a separate valve in for it. The drains shouldn't matter, they are drains. As long as the traps are in a warm area and the lines are pitched well. Old houses suck. ADDITION existing exterior wall Plumbing ( H 0 C 0 H 0 C 0 ) from basement __newwall_____________________________

- Q: can one use palstic rollers on chairs on hardwood floors or rubber rollers?

- Well, you should stop reading fake diseases articles

- Q: seriously, at what point do you just go ahead and wear a tinted face-shield?

- I think the best thing for you to do is to bring it to sony service centre.

- Q: i have very rough hair..what should i do?

- No. You can make a mold out of sugru (an air drying silicone substance), or make a substance called oogoo, which is 100% silicone caulk mixed with cornstarch, and some add spirit minerals.

- Q: what are the best fire extinguishers for the home?

- take some of his clothes that he doesn't wear that much anymore and go to your local hardware store or wal-mart and buy some silver shiny spray paint and spray his clothes with it. Or you could also tie-dye some of his clothes as well with some bright colors.

1. Manufacturer Overview

| Location | Dalian, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | Mid East,Africa, South Aisa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Dalian, Port |

| Export Percentage | 20% |

| No.of Employees in Trade Department | 150 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 3,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Flexible Coupling

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 PCS pc

- Supply Capability:

- 1000 Ton Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords