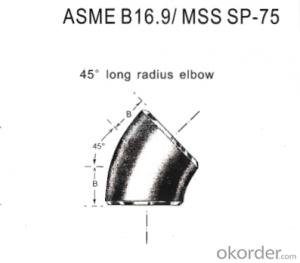

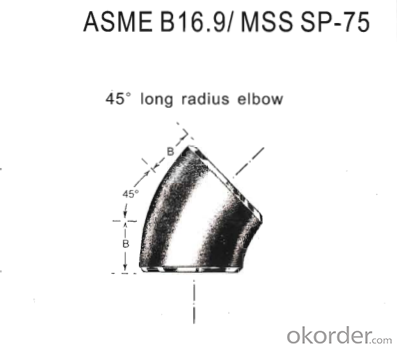

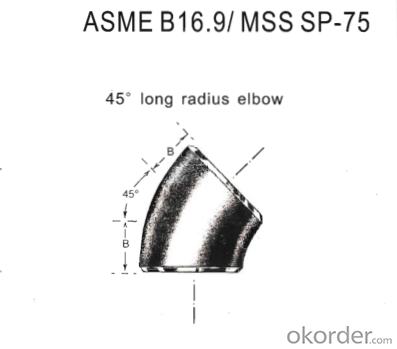

Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

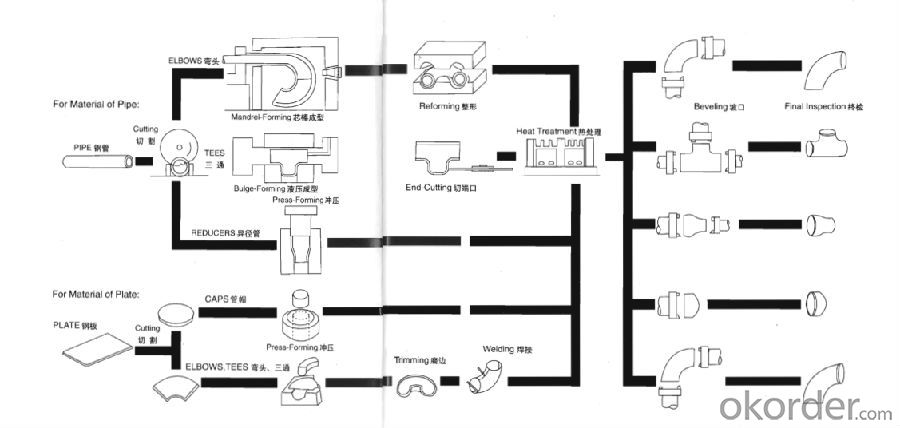

Manufacturing method and process:

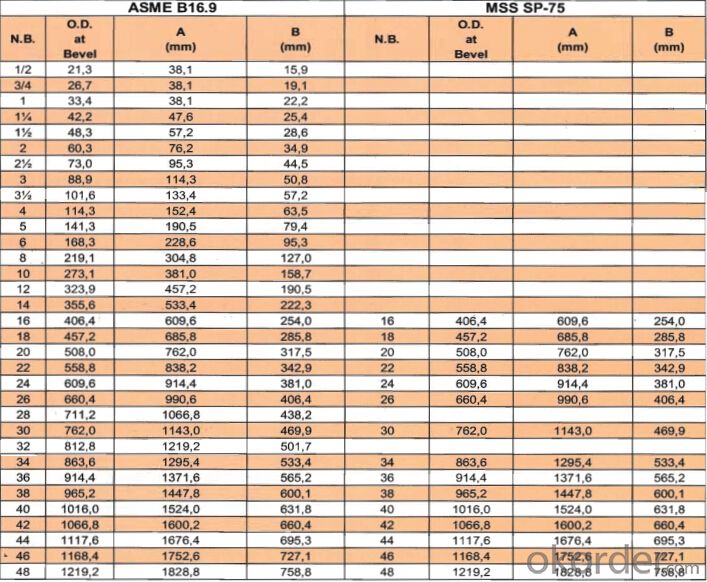

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

45° Long radius elbows:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: I'm in a chemistry lab and trying not to have a noticeable pair of goggles on. I'm looking for a pair (to buy online etc.) that is very subtle, maybe even has clear parts that rest on your ears etc.

- Suppose you have a membrane stretched as a plane sheet over a long area. if you leave a small ball on it it will remain as it is . But if you now put 1 kg at some point on the membrane and then put a small ball anywhere, you will find that the ball will run towards the heavyweight. Now you may interpret it as if the weight is attracting it or you may say that the space around the heavy weight is curved so that everything else around it tries to move towards it. Classical Newtonian gravitation makes the first kind of postulate that masses attract each other. Whereas Einstein makes the assumption that the space itself bends around massive objects. Now how do u decide the bending of space. We know that light travels in straight line. So if light travels in straight line in certain region the space is not curved but if it bends then the space is curved. This hs been verified by experiments done during Solar eclipse.

- Q: Ok, here is the deal. I had worked at this lawn care place for 2 weeks and I fell off the back of a truck and injured my knee. I was out of work for just over 3 weeks. The day i came back with my Doctor's release, my supervisor told me that he didn't want me working there anymore, that he had already hired 2 people to replace me, and that he wasn't going to re-hire me.In addition to this, he told me that he believed I was lying about having been injured and he didn't want me to work there because I got injured and it would only just happen again sometime soon. He believes this because 4 years ago, in the middle if Iraq, I got thrown off of a vehicle and minorly hurt my knee, and my Doctor told him this, so he said that it wasn't like it was a real injury because i had hur it a couple years ago too. So, basicly, I got people saying that I have no standing to ask for workers comp and I got people telling me I should Sue them for accusing me of lying about my injuries and firing me.

- You havn't a clue. Stay away. Hire someone.

- Q: I recently got my heater repaired after it was making some unusual noises. That same day, the fire alarm went off 2 times during the day and once during early hours. The next day, the fire alarm went off twice again. My alarm company claimed they had called me each time the alarm went off, but this was not the case. They alerted the fire department the fifth time without my consent, and the fire truck arrived at my house. Luckily, I was not charged but I most definitely do not want this to happen again!It's not smoke, though there is this smell that comes from the heater. What is making the fire alarm go off? There really is no problem with the heater at this point.. is my fire alarm too sensitive? Thanks for your help!

- Without knwing how old the pump is, I would guess the bearings in the pump or pump motor are starting to wear. As they wear, they will vibrate. If there are grease fittings, add a pump of grease from a grease gun. DO NOT OVER GREASE, this is onl a temporary fix. Once the bearings start to wear, they are finished and will get worse. Sorry I have no good news.

- Q: Joint type of pipe joint

- NPT is the abbreviation of National (American) Pipe Thread, an American Standard 60 degree taper pipe thread, used in North America. National standards refer to GB/T12716-1991PT is the abbreviation of Thread Pipe, is a 55 degree taper pipe thread sealing, belonging to the Whitworth family, for the European and Commonwealth countries. Commonly used in water and gas pipe industry, taper regulations of 1:16. national standard is available on the GB/T7306-2000G is a 55 degree non thread sealing pipe thread, belonging to the family of Wyeth thread, marked G for cylinder threads. National standards refer to GB/T7307-2001In addition, the 1/4, 1/2 and 1/8 marks in the thread refer to the diameter of the thread size, in inchesYes, my wife usually refers to the size of the thread by one point, one inch equals 8, and 1/4 inches is 2, so by analogy

- Q: I do I know if I need Shock/Strut? When My SUV hit a speed bump on the left side you hear a noise loud, Then when I hit the 2 speed bump the noise is not that loud as the first one. Any Suggest?

- It's not. The ports are all marked on filters these days. Inlet means in to filter from pump. Waste is backwash (if a sand filter). Outlet goes to heater, chlorinator and then pool return stub out. The front of the pump is where your suction (from pool stub out) goes. Top of pump goes to filter. Just make sure you have all the plumbing fittings and pipe handy. A roll of teflon tape as well. If this is all poly plumbing you'll need a propane torch to heat the pipe at the fittings and gear clamps.

- Q: Best Answer will get 10 points !!Ok I have a Whirlpool LEC8858EQ0 DryerIt Starts and Runs for about 10 mins then shuts off, It was making a bit of a louder noise recently, it will stay off and then all of a sudden as long as the knob is still on the dryer selection it will come back on, (Maybe after it cools)Do /Should I replace the Thermal Fuse ?Id like to replace the whole damn thing but I cant I dont have the money, and the room is built around the machine so that creates another HUGE problem.Does anyone have any suggestions ? I opened it up cleaned out any dust and lint and Im thinking maybe the thermal fuse ?PLEASE HELP BEST ANSWER GETS 10 !!

- Won't stop beeping until new batteries are replaced or you unplug the whole unit from the wall and throw it in the trash.

- Q: What do you mean by "s" in the standard of pipe joint?

- Did the landlord say "S" and "L"? S is a high voltage application, for example, at the P port. L is low voltage applications, generally used only in the oil return.

- Q: Why do dogs pee on anything upright? Tree, fire hydrant etc?

- I am a little confused about your questions Please open the door with the company and see if he was fired for just attendance or a combination of things, If he can prove that his attendance was not the problem you have a case for a suit against the company. I don't think that face-book or other social networks can be used in this fashion. My best advice is to contact a lawyer and see what they have to said on this matter. Good Luck

- Q: If you had a lightning rod that was six meteres thick at the top and it tapered down to thousands of powerlines at the other end ,thousands of kilometers away,could you harness and use the power of energy.The first section that is six meteres thick runs for 300 kilometers where in then tapers down to five metres thick.After another 700 kilometers the five feet thickness tapers down to four metres thick.After another 1000 kilometers the four feet thickness tapers down to three metres.After another 500 kilometers the three meteres tapers down to 100 ,one metre thickness.After another 500 kilometres the 100,one metre thickness tapers down to one foot thickness.This process continues until it finaly reaches 10,000 normal power lines.Would metal this thick hold enough electricty and conduct it long enough to use at the other end.Thousands of kilometres away.Would most of the energy be lost on the way.If 50,000,000 volts hit the rod at the start.How much energy would be left at the end.

- you can use teflon tape or 5 rector seal around the threads. (5 works better and will make it easier to thread as it will lube the threads also). Be carefull using a metal wrench as you can crush the fittings. Plastic pipe fittings don't require alot of tighting. Best way to tighten, is to tighten the fitting, snug. then back off a little bit and snug it up some more.

- Q: I know about the tent and sleeping bags. But for fire and food and going to the bathroom etc

- yes it is cause it keeps your hands safe i am a nursing assiant and i have to gloves all the time

Send your message to us

Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords