Stainless Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

Features standards and products of our butt welding fittings:

Features of Butt-Welding Reducing Outlet Tees:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Reducing Outlet Tees:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Reducing Outlet Tees:

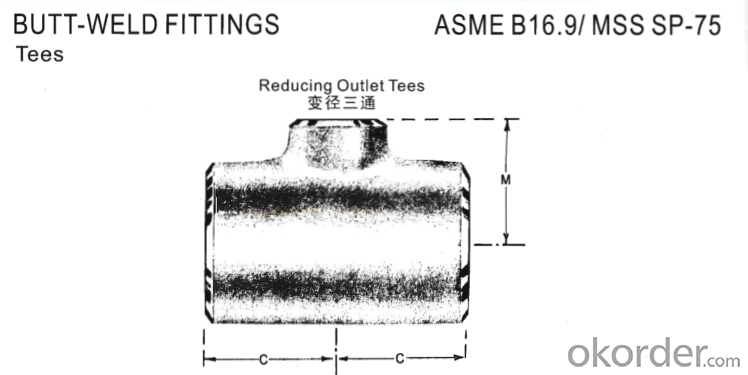

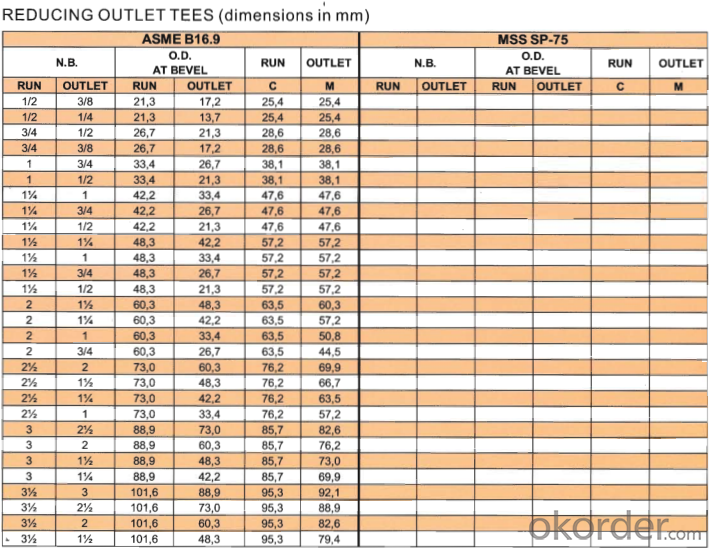

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Reducing Outlet Tees:

Packing of Butt-Welding Reducing Outlet Tees:

FAQ of Butt-Welding Reducing Outlet Tees:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:why did my mom put a smoke detector in my room!?

- Been a plumber over 40 years. What you have now is pure junk. You will surely be removing sheetrock.Type L hard copper would be a permanent and sure way to a trouble free system however being from the old school I have no faith in shark bites being buried in a wall. The only sure way is to sweat it together. It takes more time, but is well worth it. The only reason these new fangled ways of joining pipe and fittings, is because not many people can sweat copper any more. If this job is put in right you probably won't need a regulator unless your your pressure is off the map. Hope this helps.

- Q:Ok, so at night, I'm in constant fear the smoke detector will go off. No clue why. How can I get rid of it?

- and with ur chest, like mine, just what kind of race car could girls our size fit into? :)) and do they MAKE firesuits that big in the chest for us??

- Q:Does anyone have an actual safety answer or a BS answer customers would believe?

- what sharts around, sharts around, well that didnt make any bukkin sense - no shart shields if you feel bad, hand them some T.P.

- Q:Have you ever had a day where you view everyone else as dogs and you are the fire hydrant?

- Surge protectors help protect electrical equipment.

- Q:home security alarm was activated by a remote - not ours. has it ever been reported that a car alarm activated a home security alarm?

- I would say that the most dangerous aspect of not measuring groove depth would be the reduction in wall thickness. If the groove depth is not checked, it is possible that the groove could be too deep in the pipe, causing a weak point where the pipe could rupture. Even if it doesn't happen during the pressure test, the corrosion allowance of the pipe is reduced to the point that a small amount of corrosion could result in failure. If the grooves are too deep the Victaulic fittings will also not limit the angle of adjoining pipes as designed. This could potentially lead to leaks. Although I don't think this is likely given the hydraulically loaded gasket design.

- Q:A fire hose ejects a stream of water at an angle of 31.1° above the horizontal. The water leaves the nozzle with a speed of 32.0 m/s. Assuming that the water behaves like a projectile, how far from a building should the fire hose be located to hit the highest possible fire?In meters

- Speed isn't absolute. We are visiting at hundreds of km/s relative to a couple different objects in the universe. So if we get special answers for pace when measuring from one-of-a-kind features it's not ever possible to say how quick we are relocating. Thus the speed that we would journey at ( relative to the earth) is rather limitless. There are no in poor health effects of the pace itself. There can also be unwell effects of excessive acceleration. However that may be a thoroughly one-of-a-kind problem. Or ill effects triggered by a car that is not sufficient for the stipulations that it is subjected to. Eg a airplane in the surroundings have to stand up to the temperature and friction of the air. Once more this is not the velocity but effects neighborhood to being too close to the earth.

- Q:My boyfriend put a load of clothes into the dryer last night. It made a knocking noise, then the barrel slowed, and it smelled like something was burning. Now, the barrel won't turn on at all. What's going on?!

- List The Fixtures ,piping , Fittings . Etc. And Then Tools and EQ (equipment). Use A House ( In Mind ). 2) Talk To A Real Living Plumber. Get An invoice of a Real Live Renovation. P.S. Same Trick With A Roof JobOld Audel Manuel If You Can Find / Ask a Librarian For Audel Manuel Hang In There

- Q:Should I spend more on these lenses that reduce glare from headlights and fight reflections that cause eye strain and fatigue.The lenses will have less glare making them look invisible. Should I spend the extra money or will ordinary lenses do just fine

- NoIt is usually recomended you don't use a sealer on flare fittings.Can make a mess

- Q:I need to wake up early in the morning? Do laptops have an alarm option?

- Exhaust piping is commonly made up of carbon steel . You can get carbon steel exhaust piping with and aluminzied coating which tends to protect it from corroding to soon. The next level is 304 stainless which has even better corrosion resistance due to the lower carbon content. On the high end is 314 and 316 stainless. To check the property of the metal stick a magnet on it . If it is carbon steel or aluminized steel the magnet will stick to it. If it is 304 , 314, 316 the magnet won't stick. Dont use a oxy/act system if you are not experienced with it . You will end up torching your car. Use a sawzall / reciprecating saw aloneg with safety goggles for the eyes. Once you figured out your design take the pipe to a muufles shop and have them expand the ends . They will charge you around $20 . Long term savngs compared to the oxy/act system . Its old skool. Plasma cutters are the in thing now

- Q:Outside the wire (wire) of what the standard joint size

- The metal joint is made of zinc alloy. The surface is zinc plated, sanded or chrome plated. The structure is close, without porosity and high strength. Reliable connection with metal hose, beautiful appearance;The metal joint is an end connection and a linear connection for connecting the metal hose to the case;It is recommended to use an inch metal hose joint or a metric thread metal joint;Can be customized a variety of non-standard metal hose joints, special metal joints.Ferrule type metal joint

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords