Galvanized Steel Profile /100 Stud for Dry Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

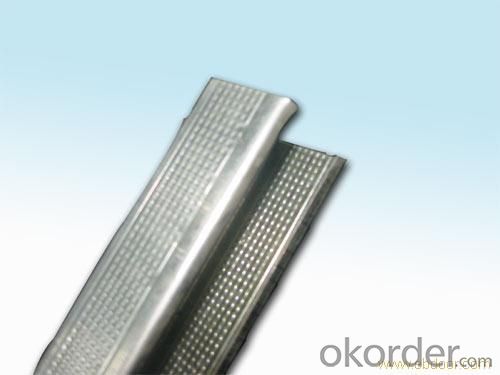

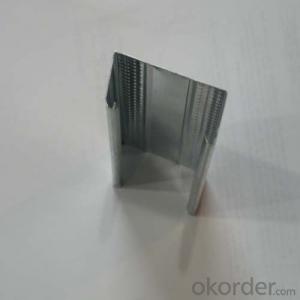

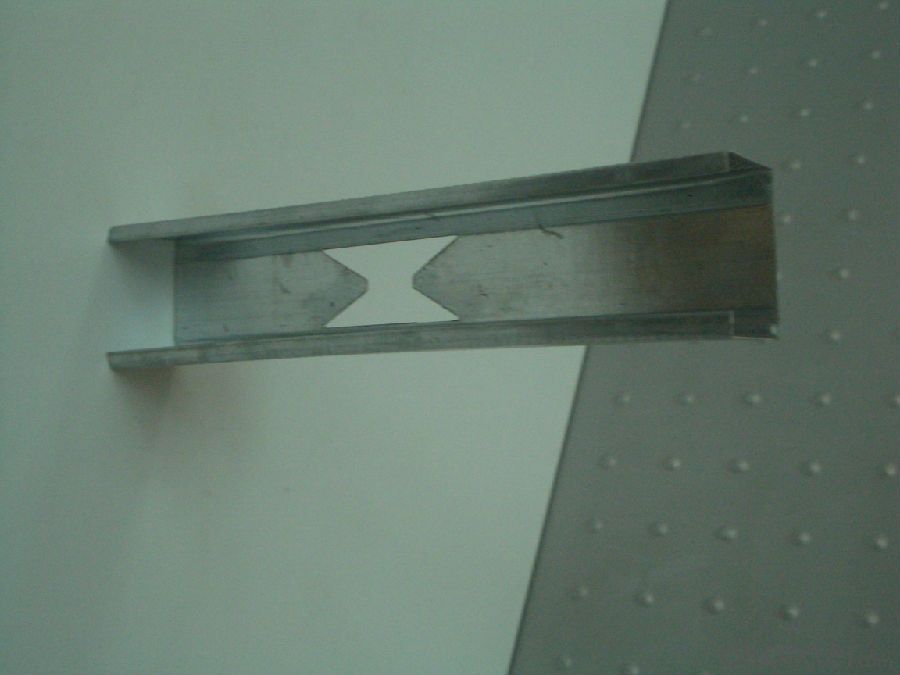

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

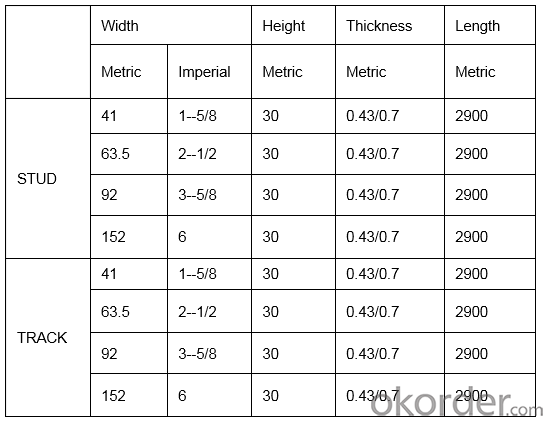

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q:Light steel keel wall Why use gypsum board to do grass-roots level?

- It is not necessary to use gypsum board but gypsum board there are many other materials can not replace the advantages of easy paint on the paint, such as latex is also its weight is more suitable for the keel does not have too much pressure on the pressure there are other advantages One by one in detail the gypsum board used in light steel keel partition is a good choice.

- Q:Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- Light steel keel wall moisture resistance is poor, even with glass magnesium board, Ette board and other moisture-proof sheet, but still not suitable for high water requirements of the bathroom, there will be hidden.

- Q:Light steel keel gypsum board partition design should pay attention to what the problem

- Each brand installation and installation methods and characteristics will be different, I will take the Nexu light steel keel brief description of the next.

- Q:100 light steel keel 9.5mm thick gypsum board double double-sided partition three times, three times latex paint.

- Light steel keel a 3 meters, just the height of the wall is 3m, vertical wall keel is not a waste of material.

- Q:Light steel keel wall cheap or cheap red brick

- Of course, is the light steel keel, probably in 70 a square, wall, then 12 of the wall art manual brick is 80, double-sided batch of 30, is 110!

- Q:Decoration decoration works Light steel keel wall, layer 4 meters high thickness What are the requirements? There is no specific specification?

- Built-in steel structure Light steel keel wall construction technology - "Ridge built-in embedded steel components (along the keel fixed screw and wall equipment, fixed support frame) + Ridge + light steel keel wall + ", That is, in the ridge before the construction, will be along the keel fixed screw and wall equipment, fixed support frame fixed fixed; the use of ridge within the fixed screw to the keel and fire insulation cotton fixed on the ridge, Between the keel and the top of the floor, between the keel keel and the wall paving a layer of fireproof sound insulation cotton, forming a damping layer, reducing the amplitude; outsourcing gypsum board as a panel to form a lightweight wall. According to the use of functional requirements and design requirements, in the panel filled with sound insulation, fire, insulation and other filling materials.

- Q:What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- The effect is certainly not the same or the cement mortar is really some wall after the installation of the socket is not vague. The

- Q:Light steel keel + gypsum board + surface brush latex paint partition wall per square meter offer is how much?

- Different local prices are different, but now artificial up, 150 may not find, there is a problem, that is, those who labor market, in general, the level is quite not how!

- Q:Light steel keel wall and wood which low cost

- Should be a wooden keel, the general family decoration with a wooden keel on it, wood keel cost is low, to meet the family use, light steel keel cost high, but high strength. It is recommended to use wood keel

- Q:Light steel keel wall how much money a square

- Steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, construction is simple Deformation and other advantages.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Profile /100 Stud for Dry Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords