CE Approved Steel Tracks For Installing The Steel Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a manufacturer of steel keel with well-equipped testing equipment and strong technical force.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in decoration and other industries.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs.

Product Applications:

purlin and wall beam of steel structure building

The C-shaped purlins have excellent anti-bending property and are easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6. We can supply you the products based on your specific requirements

7.We have many kinds of light steel building keel that could make different products accroding to Germany ,Japan,Autralis and USA

Main Product Features:

1). Commponents: main tee, long cross tee, short cross tee and wall angle.

2). Unique click design for easy connection.

3). Widely usage for the suspension system of hotel, school, hospital, shopping mall, etc.

4). Nice outlook with competitive price and good quality.

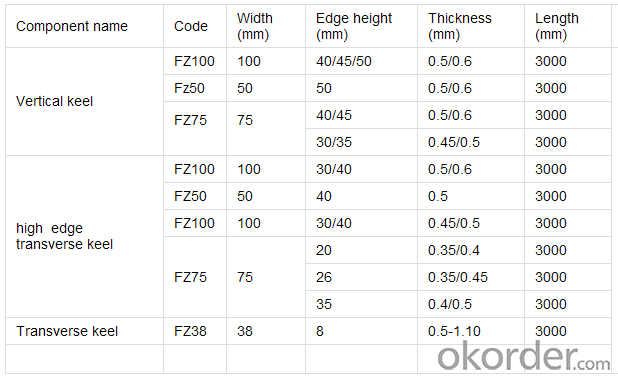

Product Specifications:

Images:

- Q:Shanghai light steel keel ceiling, wall quotes

- Depends on the use of good and bad materials. Ordinary ceiling also 30-40, partition 35-45, I was doing this is what the project. Can contact me. Offer

- Q:Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- Light steel keel (generally with gypsum board) wall lightweight, easy construction, low cost, a large number of indoor partitions,

- Q:In Shanghai 75 partition wall light steel keel 0.6 what price now

- Low-grade 3.5-4.5 yuan / m range. Light steel keel, flower head a lot. Side high, the actual thickness, galvanized surface, strip material are very affected price.

- Q:What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board partition can be said that the construction industry is now the forefront of science and technology, originated in Japan, because Japan is earthquake-prone countries, the seismic performance of the wall is very particular about, and high prices in Japan, Too high, so the house designers have invented the light steel keel inorganic composite board partition. Light steel keel inorganic composite board wall composed of light steel keel and double-sided inorganic composite panels, up and down wrapped sound insulation pad, with a solid and reliable, practical and practical features, and the thickness of only about 175px, 300px than the average wall thin. One inorganic composite board for the new inorganic composite materials, environmentally friendly materials, non-toxic and tasteless, excellent physical properties. It is composed of silicon, calcium and magnesium composite cementitious materials, and is applied by polymer composite technology. With fire-retardant, heat insulation, waterproof, waterproof, pest control, mildew, light, high strength, environmental protection and energy saving, construction fast, easy to finishes and so on. Light steel keel and inorganic composite board composed of light steel keel inorganic composite board partition wall as a partition, with strong earthquake resistance, sound insulation, easy to dismantle modification and space saving and other characteristics, a market will be favorable by the Japanese market , Has been widely used in foreign countries.

- Q:Light steel keel wall how to calculate

- Light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, Interior decoration, ceiling and other places. Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on. Process: In order to avoid the root wall vulnerable to moisture, deformation, mildew and other quality problems, the bottom of the partition to be made pillow base;

- Q:Light steel keel wall circuit how to wear pipe

- Install the crossed keel (lower threshold). Fixed with a nail, or first drilling, and with the expansion bolts connected to fixed. Installation should be installed according to the center line and edge, both ends of the top to the structural wall (column) surface, the final fixed point from the structure of the facade should not be greater than 100mm; nail or expansion bolt spacing should not be greater than 800mm. Installation should ensure that the keel level and straightness.

- Q:Light steel keel gypsum board partition should pay attention to what quality problems

- Bathroom, bath and other multi-water room and high humidity room light steel keel gypsum board wall of the root, the application of C15 concrete to do 120mm high wall base. Gypsum board seams should be used by the manufacturers supporting the supply, dedicated to the joints with the caulking paste and cap joints to ensure that the quality of gypsum board joints.

- Q:To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With a hammer to drill the ground hole can be fixed to the ground. With glue, it is certainly impossible to nail

- Q:Light steel keel gypsum board wall height is how to determine

- According to the British standard BS5234, different use of the partition wall has different stiffness requirements, the maximum height of the partition wall to determine the criteria for a certain surface load W conditions, the wall of the maximum deflection y does not exceed L / 240; The maximum deformation can not be greater than the L / 240 well system under the 200Pa uniform load. The wind load is superimposed and the uniform load will become larger

- Q:Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Home with several levels? You can use benzene board, in a good extrusion, in the good is the polyurethane and phenolic, the cost will be high. Phenolic is nonflammable. Benzene and extruded can not reach fire

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CE Approved Steel Tracks For Installing The Steel Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords