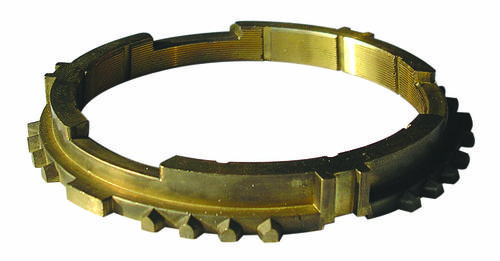

HINO GEARBOX SYNCHRONIZER RING

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Applicable models:HINO KR EH700/421

OEM:33371-1051

Outer diameter:109.25 mm

Weight :172 g

Hight:11.3mm

Actual teeth:24

Material :copper

Package:

- Q: I drive a 95 Ford Escort, the fifth gear has gone out. Right now it seems like the best option I have is rebuilding the transmission. Looking through my repair manual I am finding that there are several tools needed for the job that I do not have. These tools include an engine support bar and a transmission jack. Can I do this job without these tools and if not how much am I looking at paying for the rebuild including these tools if I do the labor myself?

- of the dozens of tools need an engine support and jack are LEAST needed,,,, 1 knowlege,,,have you ever seen a transmission appart? OMG why not let a tranny guy do the tranny 2 better yet,,junkyard,,,the whole car isnt worth the price and trouble of a tranny for price of rebuild you can get a whole running 1995 escort my sister got one for 800

- Q: Dont see a place to put in transmission oil in my car. I see the stick that tells me how much transmission oil is in the car. I LOOKED EVERYWHERE! Its a older model car. Its a 1995 Toyota Tercel.

- transmission fluid is usually added through the transmission fluid dipstick. you may need a slender funnel, or they sell transmission funnels which is basically just a funnel with a tube attached. Do not fill too fast or else you will have a mess. Be sure you are using the proper technique to check the level of your transmission fluid. It is different for different makes of cars.

- Q: i have infiniti j30, 1994. Does anyone know how many transmission mounts it has? One auto service told me there are 3 of them. Another says it has only one. i got lost

- On front wheel drive cars, the engine and transmission are one unit, making it difficult to say whether a mount is an engine mount or a transmission mount. On most cars, there is one front and center, right where the engine and transmission join. There usually one on the engine side, one on the transmission side, and there is usually a torque bar on the back (firewall side). Basically, there are three mounts total, but only one is a true transmission mount.

- Q: is the manual transmission on the Audi a4 still the cvt tranny?

- The manual model of the car is a manual, otherwise it's auto!

- Q: My transmission makes a rattling noise whenever idling in reverse or drive. It also is beginning to shake around 15-20mph. Anything over and the car is fine. I checked the trans. fluid and it is a greyish brown color. Any advice on what the problem is and how to correct it?(Note: I drive a 1996 Jeep Grand Cherokee Limited with a 4.0L inline 6 cylinder engine with about 129,000miles on it and an automatic transmission with less than 40,000 miles)

- Superconductors block magnetic fields. This is called the Meissner effect.

- Q: Is there a way i can buy an automatic transmission car and tune it up and have it be as fast as a manual transmission car?. Is there other ways i can drive a manual transmission like in crank or the transporter i forgot which one he was driving a lambo and it had the manual transmission button right under the steering wheel.

- The manual button in steering wheel are called padel shifters. The transmission is automatic but can act manual as well. this is called Triptonic. You can even shift and change gears on the shifter as well. not like a manual but either up or down, up for higher gears down lower, and as well as left and right for european cars. left lower and right higher gears. I have a Mercedes SLK with a 7 speed triptonic and uses the left and right shift sequence . when i dont need it, i shift to the highest gear and the the D(drive) symbol will appear. This will make the car shift through all 7 gears as needed on its own

- Q: The transmission is already out the car

- Its supposed to warp the intake valves when its hot and You turn it off , Its a 4cyl? Just fix it, Dont drive it like that, people will laugh at You, and it wont feel any faster,,I have done that many times but I had a 383 ci. Big-block Roadrunner w./ 400 HP. Its ok then, the flames and sound coming out was way cool, and scared people , but the Police dont really like that sort of thing any more,,

- Q: What are good tips for driving a manual transmission car?

- constaly check change oil! check clutch fluid to! when stop lights click down to nutral instead of using the clutch so much! don't just change gears fast, make sure u do it right! try to get the hihg revs before changing gears (right in the middle of the red zone, then change gears, u don't wanna over rev or short shift) changing gear right will keep ur transmission alive for so much longer so do it carfully! cause their frican expensive!

- Q: I want to put transmission fluid in my car and I was wondering where is the location of the transmission in a Honda Civic LX 2001? I cant seem to find it anywhere,

- if you don't know how to put it in, then how do you know it needs some? Just asking because thats how you put it in an auto.

- Q: Today my 1994 Chevy g10 beauville van stopped working due to transmission problems. I took it to the shop on the corner that does some of our repair work, but we have been noticing them getting higher and higher with their prices, so here is my question:What is a general estimate to repair/replace the transmission in the van? They said between $1,400.00-$1,800.00, but they aren‘t doing any of the work, they are just sending it to a transmission shop.I‘m getting the feeling it may be cheaper in other places and it‘s just so much because they want to make money off of the referral. Anyone else think I should go somewhere else and try to see what they say? I can‘t move the van with it being messed up though so will the other shops be able to get a accurate estimate to give?Just ranting. Thanks for looking.

- yeah you can, just get the model, and ask at the bike shop, if they dont have it in stock, theyll order is for ya.

Send your message to us

HINO GEARBOX SYNCHRONIZER RING

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords