Concrete Fiberglass Chopped Strand

Concrete Fiberglass Chopped Strand Related Searches

Chopped Strand Fibreglass Fiberglass Chopped Strand Mat Chopped Strand Fiberglass Mat Zccy Fiberglass Chopped Strand Mat Chopped Strand Chopped Fiberglass Chopped Glass Fiber 300G/M2 E-Glass Chopped Strand Mat B Grade Chopped Strand Mat Fiberglass Strands In Skin Surfboard Fiberglass Repair Concrete Shotcrete Car Fiberglass Concrete Resurfacing Fiberglass Drywall Fiberglass Roving Flexible Plastic Concrete Forms Fiberglass Patio Roof Fiberglass Woven Bondstrand Fiberglass Pipe Waterproof Concrete Blocks Fiberglass Yarn Woven Fibreglass Fiberglass Fabric Form Work Concrete Forming Concrete Fiberglass Cloth Roll Fiberglass Woven Fabric Fiberglass Pipe Shaver Fiberglass Thermal InsulationConcrete Fiberglass Chopped Strand Supplier & Manufacturer from China

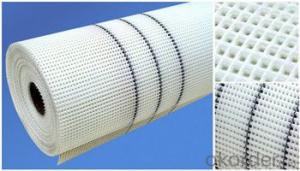

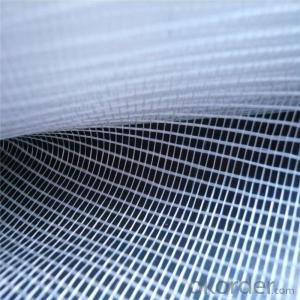

Concrete Fiberglass Chopped Strand is a type of reinforcing material that is widely used in various construction applications due to its high strength and durability. This product is made from a blend of fiberglass fibers that are chopped into short strands, which are then mixed with concrete to enhance its structural integrity and resistance to cracking. The incorporation of Concrete Fiberglass Chopped Strand into concrete mixtures significantly improves the overall performance of the material, making it ideal for applications such as bridge decks, parking structures, and industrial flooring.The usage scenarios for Concrete Fiberglass Chopped Strand are vast, as it can be utilized in both residential and commercial construction projects. It is particularly beneficial in areas where there is a high level of foot traffic or heavy machinery, as it helps to distribute the load evenly and prevent damage to the concrete surface. Additionally, Concrete Fiberglass Chopped Strand is resistant to many of the environmental factors that can degrade concrete over time, such as moisture, chemicals, and temperature fluctuations. This makes it a popular choice for use in harsh climates and industrial settings.

Okorder.com is a leading wholesale supplier of Concrete Fiberglass Chopped Strand, offering a large inventory of this high-quality product to customers around the world. With a commitment to providing exceptional customer service and competitive pricing, Okorder.com has become a trusted source for contractors and construction companies looking to purchase Concrete Fiberglass Chopped Strand in bulk. Their extensive selection and reliable supply chain ensure that customers can always find the specific type and quantity of Concrete Fiberglass Chopped Strand they need to complete their projects successfully.

Hot Products