Fiberglass chopped strand mat high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

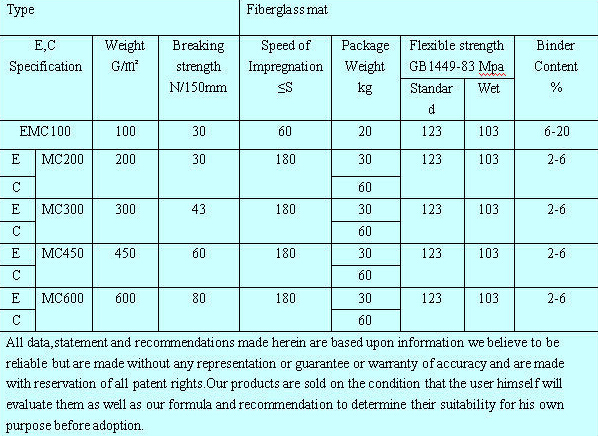

.The Style including the EMC100,EMC200,EMC600.EMCL600.EMCL450,CMC300.CMC450....

2.General width 1040mm/1270mm

3.chopped strand mat is made of randomly dispersed with power or emulsion bonded.

4.Applicable for hand lay -up ,continuous lamination process,compatible with UP VE

5.Suitable for transparent panels,ship ,bodies,automobile parts and interior decorations....

Style :

Packing :

each roll is packed by polyester bag .

2.Every roll in a cardbord box or thhr plastic woven bag

3.30kg with a rollof woven roving

4.Bordbox size : 22*24*114cm

5.The details as per customes requriments

- Q: What is the dimensional stability of fiberglass chopped strand?

- The dimensional stability of fiberglass chopped strand refers to its ability to maintain its shape and size under various conditions. Fiberglass chopped strand is known for its excellent dimensional stability, meaning it retains its shape and size even when exposed to extreme temperatures, moisture, or mechanical stress. This stability is attributed to the inherent properties of fiberglass, such as its high strength-to-weight ratio and low coefficient of thermal expansion. Additionally, the random orientation of the chopped strands enhances the stability by distributing any potential stress or strain throughout the material. Overall, the dimensional stability of fiberglass chopped strand makes it a reliable and durable material for various applications, including reinforcement in composites, insulation, and construction.

- Q: How does the moldability of the chopped strand affect its performance?

- The moldability of the chopped strand has a significant impact on its performance. The moldability refers to the ability of the chopped strand to conform and adapt to the shape of the mold during the manufacturing process. When the chopped strand has good moldability, it can be easily molded into complex shapes with intricate details. This allows it to be used in a wide range of applications where precise molding is required, such as automotive parts, aerospace components, and consumer goods. On the other hand, if the chopped strand has poor moldability, it can result in various performance issues. It may not fully conform to the mold, leading to gaps, voids, or uneven distribution of fibers. This can compromise the structural integrity and strength of the final product. Additionally, poor moldability can make it difficult to achieve consistent and uniform thickness, resulting in dimensional inaccuracies and variations in the finished product. Therefore, the moldability of the chopped strand is crucial in ensuring the overall performance and quality of the final product. By selecting a chopped strand with good moldability, manufacturers can achieve better structural integrity, dimensional accuracy, and overall performance in their molded products.

- Q: What are the typical thermal expansion properties of chopped strand composites?

- The typical thermal expansion properties of chopped strand composites can vary depending on the specific materials used and the manufacturing process. However, in general, chopped strand composites tend to have lower thermal expansion coefficients compared to traditional materials such as metals. Chopped strand composites are made by combining reinforcing fibers, such as fiberglass or carbon fibers, with a polymer matrix, such as epoxy or polyester. The fibers provide strength and stiffness to the composite, while the matrix holds them together and protects them from external factors. The thermal expansion properties of chopped strand composites are primarily influenced by the thermal expansion coefficients of the fibers and the matrix material. Fiberglass, for example, has a relatively low thermal expansion coefficient, which means it expands and contracts less with changes in temperature. This can make chopped strand composites more dimensionally stable compared to materials like metals, which have higher thermal expansion coefficients. Additionally, the polymer matrix used in chopped strand composites can also affect their thermal expansion properties. Different types of polymers have varying thermal expansion coefficients, and the specific matrix material chosen can be tailored to optimize the composite's overall performance and thermal expansion characteristics. Overall, chopped strand composites tend to exhibit lower thermal expansion properties compared to metals, making them suitable for applications where dimensional stability is important. However, it is important to note that the exact thermal expansion properties can vary depending on the specific materials and manufacturing processes used, so it is necessary to consult the manufacturer or technical specifications for precise information.

- Q: Can fiberglass chopped strand be used in the production of sporting goods?

- Yes, fiberglass chopped strand can be used in the production of sporting goods. Fiberglass chopped strand is a versatile material that offers several benefits for the manufacturing of sporting goods. It is lightweight, strong, and has excellent tensile strength, making it ideal for applications that require durability and high performance. In sporting goods production, fiberglass chopped strand is commonly used in the construction of various components such as hockey sticks, tennis rackets, golf clubs, and bicycle frames. Its high strength-to-weight ratio allows for the creation of lightweight yet robust products, enhancing the performance of athletes. Fiberglass chopped strand is also resistant to corrosion, which is beneficial for sporting goods that are exposed to moisture or outdoor elements. Furthermore, fiberglass chopped strand can be easily molded into different shapes and sizes, allowing for the production of complex designs and custom-made sporting goods. Its flexibility and ability to bond well with different resins make it an ideal material for creating composite structures that are strong and durable. Overall, fiberglass chopped strand is a suitable material for the production of sporting goods due to its lightweight, strength, durability, corrosion resistance, and versatility in manufacturing processes.

- Q: What are the tensile strength properties of fiberglass chopped strand?

- The tensile strength properties of fiberglass chopped strand refer to its ability to withstand pulling or stretching forces. Fiberglass chopped strand typically exhibits high tensile strength, making it a strong material for applications where resistance to tension and pulling forces is crucial.

- Q: Does fiberglass chopped strand have any anti-microbial properties?

- No, fiberglass chopped strand does not have any anti-microbial properties.

- Q: How does the fiber-matrix interfacial shear strength of fiberglass chopped strand affect the performance of composites?

- The fiber-matrix interfacial shear strength of fiberglass chopped strand plays a crucial role in determining the performance of composites. This parameter refers to the strength of the bond between the fiberglass fibers and the matrix material in a composite. The interfacial shear strength directly affects the load transfer capability between the fibers and the matrix. A higher interfacial shear strength means a stronger bond between the fibers and the matrix, resulting in better load transfer and improved mechanical properties of the composite. When the interfacial shear strength is high, it allows for efficient stress transfer between the fibers and the matrix during loading, resulting in enhanced strength, stiffness, and overall performance of the composite material. This is particularly important in applications where the composite is subjected to high mechanical loads or structural stresses. On the other hand, a weak or low interfacial shear strength can lead to poor load transfer, resulting in reduced performance of the composite. In such cases, the fibers may not effectively reinforce the matrix, leading to premature failure, decreased strength, and lower overall mechanical properties. The interfacial shear strength also influences other properties of composites, such as fatigue resistance, impact resistance, and dimensional stability. A strong fiber-matrix bond improves the resistance of the composite to fatigue, preventing the initiation and propagation of cracks under cyclic loading. Additionally, a high interfacial shear strength helps to absorb and dissipate energy during impact events, enhancing the impact resistance of the composite. Moreover, the interfacial shear strength affects the dimensional stability of composites. A strong bond between the fibers and the matrix helps to minimize the occurrence of microcracks and debonding at the interface, reducing the potential for moisture absorption, creep, and dimensional changes over time. In summary, the fiber-matrix interfacial shear strength of fiberglass chopped strand significantly impacts the performance of composites. A strong bond between the fibers and the matrix enhances load transfer, improving mechanical properties, fatigue resistance, impact resistance, and dimensional stability. Therefore, optimizing and controlling the interfacial shear strength is crucial for designing and manufacturing high-performance fiberglass composite materials.

- Q: What are the typical end-use industries for fiberglass chopped strand composites?

- Fiberglass chopped strand composites find extensive applications in a wide range of end-use industries due to their exceptional strength, durability, and versatility. Some of the typical industries that utilize fiberglass chopped strand composites include: 1. Automotive industry: Fiberglass chopped strand composites are used in the automotive sector for various applications such as body panels, interior components, bumpers, and engine parts. These composites offer lightweight properties, high impact resistance, and excellent corrosion resistance, making them ideal for enhancing fuel efficiency and overall vehicle performance. 2. Construction industry: The construction sector extensively utilizes fiberglass chopped strand composites in applications like roofing materials, cladding systems, window profiles, and structural reinforcements. These composites provide excellent weather resistance, thermal insulation, and high strength-to-weight ratio, making them a preferred choice for modern construction projects. 3. Aerospace industry: Fiberglass chopped strand composites play a vital role in the aerospace industry, particularly in aircraft interiors and secondary structures. These composites offer exceptional fire resistance, low smoke emission, and excellent mechanical properties, thereby ensuring passenger safety and reducing overall weight in aircraft construction. 4. Marine industry: Fiberglass chopped strand composites are widely used in the marine sector for manufacturing boat hulls, decks, and other structural components. These composites possess superior resistance to water, corrosion, and harsh weather conditions, making them highly suitable for marine applications. 5. Electrical and electronics industry: Fiberglass chopped strand composites find applications in the electrical and electronics industry for producing insulating materials, circuit boards, and electrical connectors. These composites offer excellent electrical insulation properties, high dielectric strength, and dimensional stability, ensuring safe and reliable operation in electrical applications. 6. Sports and leisure industry: Fiberglass chopped strand composites are extensively used in the production of sporting goods such as skis, snowboards, surfboards, and golf club shafts. These composites provide lightweight properties, high impact resistance, and excellent flexibility, enhancing performance and durability in sports equipment. 7. Wind energy industry: Fiberglass chopped strand composites are vital in the manufacturing of wind turbine blades, where their high strength, fatigue resistance, and lightweight properties contribute to efficient energy generation. Overall, fiberglass chopped strand composites have a diverse range of end-use industries, thanks to their exceptional properties, making them a preferred choice for various applications requiring strength, durability, and versatility.

- Q: Is fiberglass chopped strand suitable for the production of roofing materials?

- Yes, fiberglass chopped strand is suitable for the production of roofing materials. Fiberglass chopped strand is a type of reinforcement material that is commonly used in the production of various products, including roofing materials. It offers excellent strength and durability, making it ideal for withstanding the harsh weather conditions that roofs are exposed to. Additionally, fiberglass chopped strand is lightweight, which reduces the load on the roof structure. It is also resistant to corrosion and has good thermal insulation properties. These qualities make it a suitable choice for the production of roofing materials, ensuring long-lasting and reliable roofs.

- Q: Is fiberglass chopped strand suitable for marine vessel hulls?

- Yes, fiberglass chopped strand is suitable for marine vessel hulls. It provides excellent strength, durability, and resistance to water damage, making it an ideal material for constructing hulls that can withstand the harsh marine environment.

Send your message to us

Fiberglass chopped strand mat high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords