high temperature resistance fiberglass chopped strand mat

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Glass fiber chopped stand mat is kind of glass fiber products which cut by glass fiber strand to the certain length, bonded with power adhesive or emulsion adhesive. The products have higher mechanical strength.

Application:

Thermal insulation and sound-absorb materials for the industrial plant, storehouse, public facilities, exhibition center, market and all kinds of indoor playground.

Product Capability:

Advanced air cleaning, thermal insulation material;

High temperature resistant, good thermal insulation performance, good sound absorption, advanced exhaust gas purity efficiency;

Easy to cut and use;

Antisepsis, aging-resistant, corrosion resistant, ensure the health of environment;

Low moisture absorption, stable physics nature.

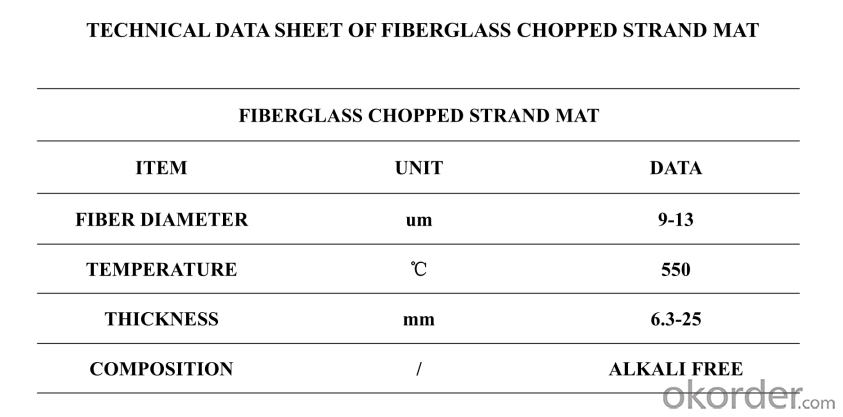

Data Sheet:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q: What are the different surface finishes available for fiberglass chopped strand?

- Some of the different surface finishes available for fiberglass chopped strand include smooth, textured, matte, gloss, and pigmented finishes.

- Q: How is fiberglass chopped strand used in the wind energy industry?

- Fiberglass chopped strand is extensively used in the wind energy industry for reinforcing composite materials used in manufacturing wind turbine blades. It is mixed with resin to create a strong and lightweight composite, providing the necessary structural integrity and stability required for the blades to withstand high wind speeds. The chopped strands enhance the overall strength and durability of the blade, ensuring optimal performance and longevity in generating clean and renewable energy from wind.

- Q: Can fiberglass chopped strand be used in the production of wind turbine components?

- Fiberglass chopped strand is indeed applicable for the production of wind turbine components. It is widely employed as a reinforcement material in the manufacturing of composite materials, including those utilized in wind turbine components. This material lends strength, durability, and exceptional mechanical properties to the final product. Generally, the chopped strand is mixed with a resin matrix and subsequently shaped or molded into the desired form, such as blades or nacelles, for wind turbines. The resulting composite material boasts a high strength-to-weight ratio, corrosion resistance, and fatigue resistance, making it highly suitable for the demanding operating conditions of wind turbines. Furthermore, fiberglass chopped strand can be easily customized to meet specific performance requirements, such as enhanced stiffness or improved impact resistance, based on the particular application. All in all, fiberglass chopped strand proves to be a versatile and efficient material for the production of wind turbine components.

- Q: Can fiberglass chopped strand be used in the production of construction panels?

- Construction panels can utilize fiberglass chopped strand as a reinforcement material, resulting in enhanced structural integrity and durability. This material is composed of randomly oriented glass fibers that are bound together with a binder. By mixing these strands with various resins, such as polyester or epoxy, a composite material is formed that possesses strength, lightness, and resistance to environmental factors. Incorporating fiberglass chopped strand into the production process of construction panels improves their strength, stiffness, and resistance to bending and cracking. Additionally, it enhances impact resistance and dimensional stability, ensuring the panels can withstand different loads and environmental conditions. Moreover, fiberglass chopped strand contributes to the fire resistance and thermal insulation properties of the panels. The glass fibers act as a barrier against heat transfer, reducing the risk of fire spreading and improving energy efficiency. To summarize, utilizing fiberglass chopped strand in the manufacturing of construction panels offers numerous advantages, including increased strength, durability, fire resistance, and thermal insulation. Therefore, it is a suitable material choice for the production of these panels.

- Q: How is the abrasion resistance of fiberglass chopped strand composites tested?

- The abrasion resistance of fiberglass chopped strand composites is commonly assessed through standardized methods like ASTM D4060 or the Taber Abrasion Test. These tests involve subjecting the composite material to controlled abrasive wear. In the ASTM D4060 test, a rotating wheel with a specific abrasive material is applied against the surface of the composite sample. This wheel exerts a predetermined load and moves in a circular path, causing abrasion on the sample. The test is conducted for a specified number of cycles or until a certain level of wear is achieved. The resulting weight loss or change in appearance of the sample is then measured to determine its abrasion resistance. Similarly, the Taber Abrasion Test employs a specialized machine that administers a particular type and level of abrasion to the composite material. The sample is mounted on a rotating turntable, and abrasive wheels or disks are pressed against the sample surface while it rotates. The test is performed for a specified number of cycles, and the resulting weight loss or change in appearance of the sample is measured to assess its abrasion resistance. Both methods yield quantitative data pertaining to the abrasion resistance of fiberglass chopped strand composites. This data enables manufacturers and researchers to evaluate the material's durability and suitability for various applications. These tests aid in the design and selection of materials that can withstand wear and deliver long-lasting performance in environments where abrasion is a concern, such as automotive components, marine applications, or industrial equipment.

- Q: What is the water repellency of fiberglass chopped strand?

- The water repellency of fiberglass chopped strand may vary depending on the specific manufacturing process and any additional coatings or treatments applied to the material. In general, fiberglass chopped strand is recognized for its excellent water resistance due to its non-porous nature and the hydrophobic properties of the glass fibers. This signifies that the material is less likely to absorb water and more likely to form droplets that roll off its surface. However, it is important to acknowledge that fiberglass is not completely impermeable and can gradually absorb water if it is not adequately sealed or protected. Furthermore, factors such as the length and diameter of the fibers, as well as the orientation and distribution of the strands within the material, can also influence the water repellency of fiberglass chopped strand.

- Q: What are the typical manufacturing challenges when using fiberglass chopped strand composites?

- Some typical manufacturing challenges when using fiberglass chopped strand composites include ensuring proper resin wet-out for effective adhesion, controlling fiber orientation and distribution during molding, minimizing voids and air entrapment, and managing the potential for fiber breakage or pull-out during processing. Additionally, the abrasive nature of fiberglass fibers can lead to increased tool wear and maintenance requirements.

- Q: Does fiberglass chopped strand improve the impact resistance of composite materials?

- Yes, fiberglass chopped strand does improve the impact resistance of composite materials. Chopped strand is made up of small, randomly oriented fibers that are mixed into the composite material during the manufacturing process. These fibers provide reinforcement and enhance the overall strength and durability of the composite. When an impact occurs, the fiberglass chopped strand helps to distribute the force and absorb the energy, preventing it from concentrating in one area and causing damage. The fibers act as a barrier, absorbing and dispersing the impact energy throughout the composite material, thereby reducing the likelihood of cracks or fractures. Furthermore, fiberglass chopped strand enhances the interfacial bonding between the fibers and the matrix of the composite, improving the load transfer capability. This increased bonding strength contributes to the overall impact resistance of the composite material. In summary, the addition of fiberglass chopped strand to composite materials significantly improves their impact resistance by dispersing and absorbing impact energy, preventing localized damage, and enhancing the overall strength and durability of the composite.

- Q: How does the diameter of the chopped strand affect its performance?

- The diameter of the chopped strand can significantly impact its performance. A smaller diameter strand typically results in better dispersion and wet-out in the resin matrix, leading to improved mechanical properties and overall performance of the composite material. Additionally, a smaller diameter strand allows for higher fiber loading, increasing the strength and stiffness of the final product. Conversely, a larger diameter strand may provide better impact resistance but can result in reduced flowability during processing and potentially create voids or weak spots in the composite structure.

- Q: How does the adhesion of the chopped strand affect its performance?

- The adhesion of the chopped strand plays a crucial role in determining its performance. The adhesion refers to the bond strength between the individual glass fibers and the matrix material in a composite material. A strong adhesion between the chopped strand and the matrix material is advantageous for several reasons. Firstly, it ensures effective load transfer between the fibers and the matrix, leading to improved mechanical properties such as tensile strength, flexural strength, and impact resistance. The load transfer is essential because the fibers are responsible for carrying the majority of the load in a composite material. A weak adhesion could result in poor load transfer, leading to lower overall performance. Secondly, a strong adhesion helps in preventing fiber pull-out. Fiber pull-out occurs when the fibers are not firmly bonded to the matrix and are pulled out during loading, reducing the efficiency of the composite material. With a good adhesion, the fibers remain embedded in the matrix, providing continuous reinforcement and enhancing the overall strength of the material. Furthermore, a strong adhesion also improves the resistance of the composite material to environmental factors such as moisture and temperature. A weak adhesion can lead to reduced resistance to these factors, resulting in degradation and reduced performance over time. In summary, the adhesion of the chopped strand significantly affects its performance. A strong adhesion ensures effective load transfer, prevents fiber pull-out, and enhances resistance to environmental factors, ultimately leading to improved mechanical properties and durability of the composite material.

Send your message to us

high temperature resistance fiberglass chopped strand mat

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords