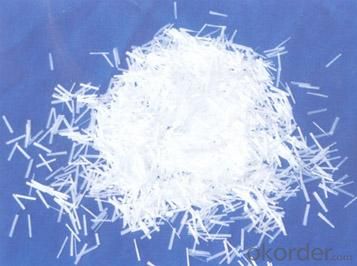

Chopped Strand Mat Fiberglass and Epoxy E Glass Fiber Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Chopped Stands for Thermoplastic are based on silane coupling agent and special sizing formulation, compatible with PA,PBT/PET, PP, AS/ABS, PC, PPS/PPO,POM, LCP;

E-Glass Chopped Stands for thermoplastic are know for excellent strand integrity, superior flowability and processing property, delivering excellent mechanical property and high surface quality to its finished product.

Product Features:

● Extremely low resin demand, delivering low viscosity to BMC paste

● High impact strength; High LOI rate

● High strand stiffness; Compatible with rubber

Product Specifications:

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

● Special specification can be produce according to customer requirements.

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving depos

- Q: Can fiberglass chopped strand be used in the production of medical implants?

- Medical implants do not typically incorporate fiberglass chopped strand as it lacks the necessary biocompatibility required for use in the human body. Instead, materials like titanium, stainless steel, and biocompatible polymers are commonly utilized in the medical field. These materials have undergone extensive testing and approval to ensure their safety and effectiveness within the body. They possess specific properties, such as corrosion resistance, tissue integration capability, and compatibility with medical imaging techniques, which render them ideal for implantation. Therefore, it is recommended to employ materials specifically designed and approved for medical implant applications to guarantee patient safety and achieve optimal performance. Fiberglass chopped strand, on the other hand, finds its primary application in industries such as automotive, aerospace, and construction.

- Q: How does the tensile strength of the chopped strand affect its performance?

- The tensile strength of the chopped strand directly affects its performance as it determines the strand's ability to resist pulling or stretching forces. A higher tensile strength indicates a stronger strand that can withstand greater stress and strain without breaking or deforming, thus leading to improved overall performance in applications such as reinforcement in composites or textiles.

- Q: What are the cost considerations when using fiberglass chopped strand?

- There are various cost considerations that must be taken into account when utilizing fiberglass chopped strand. Initially, one should consider the cost of the fiberglass chopped strand itself. This cost can fluctuate depending on the quality and type of fiberglass employed. While higher quality fiberglass may be pricier, it can also offer superior performance and longevity. In addition to the material cost, there are other factors to ponder. The expenses associated with transportation and handling should be factored in, as fiberglass chopped strand can be bulky and require delicate handling during transit. This can increase the overall cost, particularly if the material needs to be shipped over long distances. Moreover, the cost of processing the fiberglass chopped strand should be considered. This encompasses any cutting, shaping, or molding that needs to be executed on the material. Depending on the intricacy of the project and the equipment required, this can augment the overall cost. It is also crucial to contemplate the cost of any supplementary materials or components that may be necessary when utilizing fiberglass chopped strand. For instance, if the fiberglass is being incorporated into a composite material, the cost of the resin, additives, and other reinforcing materials should be factored into the equation. Lastly, the cost of labor should not be overlooked. If specialized skills or equipment are required to work with fiberglass chopped strand, additional labor costs may be incurred. This might encompass the cost of training or hiring skilled workers, as well as any extra time needed for the fabrication or installation process. All in all, when employing fiberglass chopped strand, it is vital to consider the cost of the material itself, transportation and handling, processing, additional materials, and labor. By thoroughly evaluating these cost considerations, one can make well-informed decisions to ensure the most cost-effective utilization of fiberglass chopped strand.

- Q: Can fiberglass chopped strand be used in water storage tanks?

- Fiberglass chopped strand can indeed find utility within water storage tanks. This material, known for its robustness and durability, boasts resistance against corrosion and can endure even the harshest environmental conditions. Its exceptional qualities, such as its high tensile strength, lightweight nature, and ability to withstand chemical exposure and UV radiation, make it a frequently chosen option for the construction of water storage tanks. The chopped strand variant of fiberglass is often employed during the manufacturing process of fiberglass-reinforced plastics (FRPs), which are extensively utilized within water storage tanks. Typically, these chopped strands are combined with a resin matrix, resulting in a composite material that significantly enhances the tank's strength and structural stability. Furthermore, fiberglass's impermeability renders it an ideal choice for averting water leakage and contamination. All in all, fiberglass chopped strand is a prevalent and fitting material for the creation of water storage tanks.

- Q: Does fiberglass chopped strand improve the weathering resistance of composite materials?

- Composite materials benefit from the use of fiberglass chopped strand, as it enhances their ability to resist weathering. Fiberglass is well-known for its exceptional weathering properties, making it a popular choice for reinforcing composite materials. Chopped strand fiberglass, which consists of small, randomly chopped fibers mixed with a resin matrix, is particularly effective in creating a durable composite material. The inclusion of fiberglass chopped strand in composite materials improves their weathering resistance in multiple ways. Firstly, the fiberglass fibers possess a high resistance to UV radiation, a significant contributor to weathering. These fibers act as a protective barrier, absorbing and dispersing UV rays, thereby preventing damage to the underlying resin matrix. This feature ensures the composite material's structural integrity and appearance are maintained over time. Secondly, fiberglass chopped strand reinforces the composite material, resulting in increased strength and stiffness. This reinforcement enables the composite material to withstand the mechanical stresses associated with weathering, including wind, temperature fluctuations, and exposure to moisture. By enhancing the overall strength of the composite, fiberglass chopped strand helps prevent cracking, warping, and other forms of degradation caused by weathering. Furthermore, fiberglass chopped strand improves the dimensional stability of composite materials. It minimizes dimensional changes caused by variations in temperature, reducing the risk of warping or distortion. This characteristic is particularly valuable in outdoor applications, where composite materials are exposed to a wide range of weather conditions. In conclusion, the addition of fiberglass chopped strand significantly enhances the weathering resistance of composite materials. The high UV resistance, reinforcement, and dimensional stability provided by fiberglass chopped strand enable composite materials to withstand the detrimental effects of weathering, ensuring long-term performance and durability.

- Q: Can fiberglass chopped strand be used in construction?

- Yes, fiberglass chopped strand can be used in construction. It is commonly used as a reinforcement material in various construction applications such as concrete, roofing, insulation, and composite panels. It enhances the strength, durability, and fire resistance of the construction materials.

- Q: What are the transportation considerations for fiberglass chopped strand?

- Transportation considerations for fiberglass chopped strand include ensuring proper packaging and securing the material to prevent damage during transit. Fiberglass chopped strand is typically packaged in bags or boxes, and it is important to choose packaging that is sturdy enough to withstand the rigors of transportation. In addition to packaging, it is essential to secure the fiberglass chopped strand properly to prevent shifting or movement during transport. This can be done by using straps or other secure fastening methods to hold the packages in place within the transportation vehicle. Another consideration is the weight and size of the fiberglass chopped strand packages. It is important to accurately estimate the weight and dimensions of the packages to ensure compliance with weight restrictions and to determine the appropriate type of transportation vehicle needed. Furthermore, it is crucial to consider any special handling requirements for fiberglass chopped strand during transportation. This may include protecting the material from extreme temperatures, moisture, or other environmental factors that could potentially impact its quality. Lastly, it is important to be aware of any regulations or guidelines that govern the transportation of fiberglass chopped strand. This could include compliance with hazardous materials regulations, if applicable, or following specific shipping requirements mandated by regulatory bodies. By considering these transportation considerations, it is possible to ensure the safe and efficient transportation of fiberglass chopped strand, minimizing the risk of damage or loss during transit.

- Q: How does the fiber orientation affect the impact resistance of fiberglass chopped strand composites?

- The fiber orientation plays a crucial role in determining the impact resistance of fiberglass chopped strand composites. The orientation of the fibers within the composite affects how the energy from an impact is distributed and absorbed. When the fibers are randomly oriented, as in a chopped strand composite, the impact resistance is generally lower compared to composites with aligned fibers. This is because the random orientation leads to a less efficient load transfer and energy absorption mechanism. The impact force is distributed unevenly throughout the composite, resulting in localized stress concentrations and potential failure points. On the other hand, when the fibers are aligned, such as in a unidirectional composite, the impact resistance is significantly improved. The aligned fibers allow for a more efficient load transfer along the length of the fibers, spreading the impact force over a larger area and reducing stress concentrations. This results in enhanced energy absorption and better resistance to impact. Additionally, the orientation of the fibers also affects the failure mode of the composite under impact. In chopped strand composites, the random fiber orientation can lead to fiber pull-out and delamination, which are common failure mechanisms. Conversely, in composites with aligned fibers, fiber breakage and matrix cracking are more likely to occur, which can help dissipate energy and prevent catastrophic failure. In summary, the fiber orientation has a direct impact on the impact resistance of fiberglass chopped strand composites. Random fiber orientation leads to lower impact resistance, while aligned fibers result in improved impact resistance by providing efficient load transfer, reducing stress concentrations, and altering failure modes.

- Q: What do the surplus of the glass fiber used for?

- The short cut fiber is used in the molding sheet or the molding compound, and also put it in the position of the hand paste glass fiber reinforced plastic with short cut fiber.

- Q: Is fiberglass chopped strand compatible with different joining techniques?

- Fiberglass chopped strand is indeed compatible with a range of joining techniques. It offers versatility as it can be connected through various methods, including adhesive bonding, mechanical fastening, and fusion welding. When adhesive bonding is used, a suitable adhesive is employed to connect the chopped strand either to another material or to join multiple chopped strand components together. Mechanical fastening, on the other hand, involves the use of screws, bolts, or rivets to establish a connection between the chopped strand and other materials. Fusion welding is yet another option, where the chopped strand components are joined by melting and fusing the fibers using heat. Thanks to its compatibility with different joining techniques, fiberglass chopped strand proves to be a versatile material suitable for a wide range of applications in industries such as automotive, construction, and aerospace.

Send your message to us

Chopped Strand Mat Fiberglass and Epoxy E Glass Fiber Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords