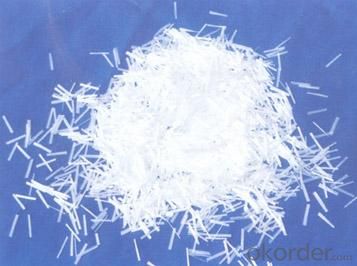

Chopped Strand Fiberglass E-Glass Fiberglass Chopped Strands for BMC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

E-Glass Fiber Glass Chopped Strands For BMC are compatible with unsaturated polyester, epoxy resin and phenolic resins.

The end-use applications include transportation, building & construction, electronic & electrical, mechanical, and light industry.

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High impact strength; High LOI rate

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Can fiberglass chopped strand be used in the production of sporting equipment?

- Yes, fiberglass chopped strand can be used in the production of sporting equipment. It is commonly used in various applications like reinforcing materials for hockey sticks, tennis rackets, surfboards, and other sports equipment, as it provides excellent strength, durability, and lightweight properties.

- Q: Can fiberglass chopped strand be used in water treatment applications?

- Yes, fiberglass chopped strand can be used in water treatment applications. It is commonly used in the construction of water treatment tanks, pipes, and vessels due to its corrosion resistance, high strength, and durability. Additionally, fiberglass chopped strand can be used in the fabrication of filtration media, such as filter beds and packed towers, to remove impurities from water.

- Q: Is fiberglass chopped strand suitable for construction reinforcement applications?

- Construction reinforcement applications can benefit from the use of fiberglass chopped strand. This material is created by chopping fiberglass strands into smaller pieces, usually around 1 to 3 inches in length. These chopped strands are then mixed with a binder and molded into mats or sheets. The advantages of fiberglass chopped strand make it an excellent option for construction reinforcement. Firstly, fiberglass is known for its strength and durability, which enhances the overall strength of structures. It possesses high tensile strength and exceptional resistance to chemicals, corrosion, and weathering, allowing for its use in various construction applications. What's more, fiberglass chopped strand is lightweight, making it easier to handle and install compared to traditional reinforcement materials like steel. This can result in faster construction times and reduced labor costs. Moreover, fiberglass chopped strand is non-conductive and non-magnetic, making it ideal for situations where electrical conductivity or magnetic interference must be avoided. It is also non-combustible, providing an added level of safety in construction projects. In conclusion, fiberglass chopped strand is a versatile and dependable material for construction reinforcement. Its combination of strength, durability, lightweight nature, and non-conductive properties make it suitable for a wide range of construction projects.

- Q: Can fiberglass chopped strand be used in the production of agricultural equipment?

- Yes, fiberglass chopped strand can indeed be used in the production of agricultural equipment. It is commonly used to reinforce and strengthen various components, such as panels, hoods, and body parts of agricultural machinery. The fiberglass chopped strand offers excellent mechanical properties, high strength-to-weight ratio, and resistance to corrosion, making it a suitable material for enhancing the durability and performance of agricultural equipment.

- Q: Can fiberglass chopped strand be used in the production of sporting goods?

- Yes, fiberglass chopped strand can be used in the production of sporting goods. It is commonly used in the manufacturing of sporting equipment such as hockey sticks, surfboards, and skis due to its high strength and lightweight properties.

- Q: How is the chemical resistance of fiberglass chopped strand determined?

- The chemical resistance of fiberglass chopped strand is determined through various tests and evaluations that measure the material's ability to withstand exposure to different chemicals. These tests typically involve immersing the chopped strand in various chemical solutions and evaluating its performance over time, assessing factors such as weight loss, physical appearance, and mechanical properties. The results of these tests help determine the chemical compatibility and resistance of fiberglass chopped strand to different substances.

- Q: How is the interlaminar shear strength of fiberglass chopped strand composites determined?

- The interlaminar shear strength of fiberglass chopped strand composites is typically determined through various testing methods, such as the short beam shear test or the double cantilever beam test. These tests involve applying a shear force to the composite material and measuring the maximum load it can withstand before failure. This provides valuable information on the composite's resistance to interlayer shear stresses and helps in evaluating its overall mechanical properties.

- Q: Is fiberglass chopped strand compatible with polypropylene resin?

- Indeed, polypropylene resin and fiberglass chopped strand are indeed compatible. Polypropylene (PP) resin is a widely utilized thermoplastic polymer across various industries due to its exceptional chemical resistance, low density, and commendable thermal stability. On the other hand, fiberglass chopped strand, composed of small glass fiber strands, is commonly employed as a reinforcement material in composite applications. By incorporating the fiberglass chopped strand with polypropylene resin, the mechanical properties of the resulting composite material, including strength, stiffness, and impact resistance, are significantly enhanced. The glass fibers serve as a reinforcement, imparting additional strength and durability to the polypropylene resin. Moreover, the compatibility between fiberglass chopped strand and polypropylene resin ensures a robust bond between the two materials, thereby promoting good adhesion. This compatibility facilitates efficient processing and manufacturing of composite parts using polypropylene resin and fiberglass chopped strand. Overall, the combination of fiberglass chopped strand and polypropylene resin is a widely adopted and harmonious system in the production of composite materials.

- Q: How does the UV resistance of fiberglass chopped strand affect its performance?

- The UV resistance of fiberglass chopped strand plays a crucial role in determining the overall performance of the material. Fiberglass chopped strand is commonly used in various applications, such as reinforced plastics, composites, and insulation materials. UV radiation from the sun can cause significant damage to materials exposed to it over time. When fiberglass chopped strand is exposed to UV rays, it can undergo a process called photodegradation. This process can weaken the material, leading to a decrease in its mechanical properties and overall performance. The UV resistance of fiberglass chopped strand is determined by the type and amount of UV stabilizers added during the manufacturing process. UV stabilizers are chemical additives that help protect the material from the harmful effects of UV radiation. These stabilizers form a protective layer on the surface of the fiberglass, which absorbs and reflects the UV rays, preventing them from penetrating the material. By enhancing the UV resistance of fiberglass chopped strand, its performance can be significantly improved. A high level of UV resistance ensures that the material retains its strength, durability, and dimensional stability when exposed to sunlight or other sources of UV radiation. This is particularly important in outdoor applications where the material is constantly exposed to the elements. In applications where fiberglass chopped strand is used to reinforce plastics or composites, a good UV resistance is essential to prevent the material from becoming brittle or losing its structural integrity. UV resistance also helps to maintain the aesthetic appearance of the material by preventing discoloration, fading, or yellowing caused by UV exposure. Furthermore, in insulation materials, a high level of UV resistance is required to prevent degradation over time. Insulation materials that are not UV resistant can lose their thermal properties and become less effective at retaining heat or preventing heat transfer. In conclusion, the UV resistance of fiberglass chopped strand directly affects its performance by protecting it from the damaging effects of UV radiation. A material with good UV resistance will have enhanced mechanical properties, durability, and longevity, making it suitable for a wide range of applications.

- Q: Can fiberglass chopped strand be used in the production of automotive parts?

- Automotive parts can be produced using fiberglass chopped strand. This reinforcement material is created by chopping fiberglass strands into smaller pieces. Its high strength-to-weight ratio, durability, and cost-effectiveness make it a popular choice in the manufacturing of automotive parts. In the automotive industry, fiberglass chopped strand is commonly utilized in the production of various components like body panels, bumpers, hoods, fenders, and interior parts. It is often combined with resin to form composite materials that possess excellent strength and stiffness properties. The length and orientation of the chopped strand can be tailored to meet specific design requirements, enabling a wide range of applications in automotive manufacturing. Moreover, fiberglass chopped strand provides several advantages for the production of automotive parts. Firstly, it is lightweight, which aids in reducing the overall vehicle weight and enhancing fuel efficiency. Furthermore, it boasts remarkable corrosion resistance, making it suitable for automotive applications that are exposed to harsh environments. Additionally, fiberglass chopped strand exhibits good dimensional stability and can withstand high temperatures, making it suitable for under-the-hood components. In conclusion, fiberglass chopped strand is a versatile and dependable material that can be effectively employed in the production of automotive parts. Its unique properties make it an excellent choice for manufacturers seeking to enhance the performance, durability, and cost-effectiveness of their automotive components.

Send your message to us

Chopped Strand Fiberglass E-Glass Fiberglass Chopped Strands for BMC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords