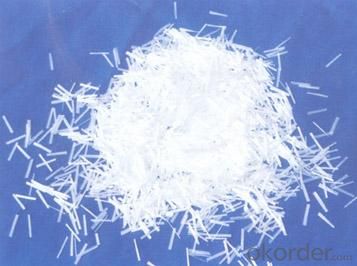

Fiberglass Chopped Strand e-glass Fiberglass for Thermoplastics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

E-Glass Fiber Glass Chopped Strands For Thermoplastics are know for excellent strand integrity, superior flowability and processing property, delivering excellent mechanical property and high surface quality to its finished product.

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: What are the dimensional stability properties of fiberglass chopped strand?

- The dimensional stability properties of fiberglass chopped strand are exceptional. This is attributed to the combination of the inherent rigidity and strength of glass fibers and the resin matrix that binds them together. The tightly bound and evenly dispersed chopped strands form a reinforcing network that resists deformation and retains its shape even when subjected to different environmental conditions and mechanical stresses. One notable dimensional stability property of fiberglass chopped strand is its low coefficient of thermal expansion. This means that it experiences minimal expansion or contraction with temperature changes, minimizing the risk of warping or distortion. This characteristic makes fiberglass chopped strand ideal for applications that demand precise dimensions, such as automotive components, boat hulls, and construction materials. Moreover, fiberglass chopped strand exhibits high resistance to moisture absorption and humidity. This characteristic prevents swelling or shrinking that could alter its dimensions. It also makes fiberglass chopped strand suitable for use in outdoor and wet environments, where other materials may deteriorate or lose their dimensional stability. Furthermore, fiberglass chopped strand demonstrates excellent resistance to chemical and solvent attacks, which preserves its dimensional stability even in corrosive environments. This property is particularly crucial in industrial settings, where exposure to chemicals or harsh substances can cause dimensional changes in alternative materials. Overall, the dimensional stability properties of fiberglass chopped strand make it a dependable and long-lasting material for a wide array of applications. Its ability to maintain its shape and dimensions under diverse conditions ensures sustained performance and structural integrity.

- Q: Is fiberglass chopped strand suitable for applications requiring high vibration resistance?

- Yes, fiberglass chopped strand is suitable for applications requiring high vibration resistance. Fiberglass is known for its excellent mechanical properties, including high tensile strength and stiffness. The chopped strand form provides additional benefits, such as improved dispersion and easier handling during application. These characteristics make fiberglass chopped strand an ideal material for applications that are subjected to high levels of vibration, such as automotive parts, boat hulls, and aerospace components. The fibers' ability to absorb and dissipate vibrations helps to reduce stress and prevent fatigue failure in these demanding environments. Additionally, fiberglass chopped strand is highly versatile and can be combined with other materials to further enhance its vibration resistance properties.

- Q: Does fiberglass chopped strand have any health hazards?

- Fiberglass chopped strand presents potential health hazards if safety precautions are not properly observed. The primary concern lies in the emission of fiberglass particles into the atmosphere, which can be inhaled and result in respiratory issues. These particles are extremely fine and can cause irritation to the skin, eyes, and lungs if adequate protective gear is not utilized. Prolonged exposure to fiberglass particles has been associated with health issues such as lung cancer, mesothelioma, and various respiratory diseases. It is important to note that the likelihood of developing these conditions is generally higher for individuals who regularly work with fiberglass, such as those in the manufacturing or construction industries. To mitigate the health risks associated with fiberglass chopped strand, it is advised to wear protective clothing, gloves, goggles, and a respirator when handling or being in proximity to fiberglass. Proper ventilation and containment measures should also be implemented to prevent the release of particles into the air. Regular cleaning and maintenance of work areas are crucial in minimizing the accumulation of fiberglass dust and debris. In conclusion, although fiberglass chopped strand does possess health hazards, these risks can be minimized by adhering to appropriate safety protocols and utilizing suitable protective equipment.

- Q: Can fiberglass chopped strand be used in the production of insulation materials?

- Yes, fiberglass chopped strand can be used in the production of insulation materials. Fiberglass chopped strand is typically made from fine fibers of glass that are randomly chopped into short lengths. These chopped strands can be used as reinforcement in various materials, including insulation materials. The fiberglass strands help to improve the strength, durability, and thermal performance of the insulation. Additionally, fiberglass chopped strand can also enhance the fire resistance of insulation materials, making them more suitable for applications where fire safety is a concern.

- Q: What are the compressive strength properties of fiberglass chopped strand?

- Various factors, including the type and quality of the fiberglass, the length and orientation of the strands, and the manufacturing process, influence the compressive strength properties of fiberglass chopped strand. However, overall, fiberglass chopped strand demonstrates excellent compressive strength. Fiberglass is renowned for its high strength-to-weight ratio, making it a favored option in industries that require lightweight yet resilient materials. The random arrangement of chopped strands in fiberglass enhances its compressive strength by enabling superior load distribution. The compressive strength of fiberglass chopped strand can vary from 300 MPa to 1,000 MPa (43,500 psi to 145,000 psi) depending on the specific composition and manufacturing technique. This puts it in the same league as many metals, such as aluminum, but with significantly less weight. To further enhance the compressive strength of fiberglass chopped strand, one can use higher-grade fiberglass materials, improve the manufacturing process, or incorporate additional reinforcement techniques such as resin impregnation or fiber alignment. It is essential to note that the compressive strength of fiberglass chopped strand may differ based on the specific application and intended use. Therefore, it is advisable to consult the manufacturer or conduct specific tests to determine the precise compressive strength properties for a particular fiberglass chopped strand product.

- Q: How does the flexural strength of the chopped strand affect its performance?

- The flexural strength of chopped strand directly affects its performance as it determines the material's ability to withstand bending or flexing without breaking or failing. A higher flexural strength indicates a stronger and more durable chopped strand, which contributes to its overall performance and suitability for various applications.

- Q: Is fiberglass chopped strand fire-resistant?

- Yes, fiberglass chopped strand is fire-resistant. Fiberglass is made from spun glass fibers, which inherently have a high melting point and do not easily catch fire. Additionally, fiberglass is often treated with fire retardant materials during the manufacturing process to enhance its fire-resistant properties. This makes fiberglass chopped strand a popular choice for applications where fire safety is a concern, such as in insulation, construction materials, and automotive components. However, it is important to note that the fire resistance of fiberglass chopped strand can vary depending on the specific product and manufacturing process, so it is always advisable to consult the manufacturer's specifications for accurate information on its fire-resistant properties.

- Q: Can fiberglass chopped strand be used in electrical insulation coatings?

- Yes, fiberglass chopped strand can be used in electrical insulation coatings. Fiberglass is a versatile material that offers excellent electrical insulation properties, making it suitable for use in various electrical applications. The chopped strand form of fiberglass can be easily incorporated into coatings, providing reinforcement and enhancing the electrical insulation capabilities of the coating. The chopped strands help to improve the mechanical strength and resistance to cracking of the coating, while also offering thermal stability and resistance to moisture. Overall, fiberglass chopped strand is a reliable option for enhancing the electrical insulation properties of coatings used in electrical applications.

- Q: How is fiberglass chopped strand typically packaged and shipped?

- Fiberglass chopped strand is typically packaged in bags or cartons and then shipped in pallets or containers to ensure safe transportation and easy handling.

- Q: Use of glass fiber cloth

- Reinforced material

Send your message to us

Fiberglass Chopped Strand e-glass Fiberglass for Thermoplastics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords