Fiberglass Mat Tissue Chopped Strand Mat for Boat Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chopped Strand Mat for Boat Building Fiberglass Mat

Introduction:

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

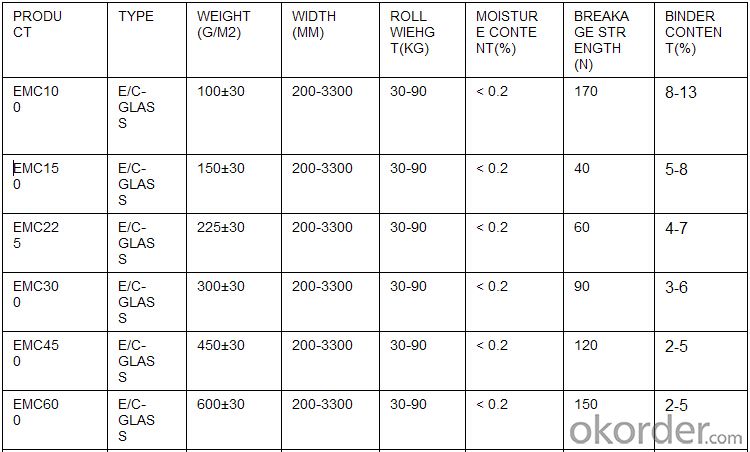

Technical Data:

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for creating molds?

- No, fiberglass mat tissue cannot be used for creating molds. Fiberglass mat tissue is a thin, lightweight material that is typically used as a reinforcement layer in fiberglass composite applications. It is not designed to be a mold-making material. Instead, materials such as silicone, resin, or plaster are commonly used to create molds due to their ability to capture fine details and provide a smooth surface finish.

- Q: Is fiberglass mat tissue chemically resistant?

- Yes, fiberglass mat tissue is chemically resistant.

- Q: Is fiberglass mat tissue resistant to fading?

- Yes, fiberglass mat tissue is resistant to fading.

- Q: Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a lightweight material that offers excellent thermal insulation properties. It can effectively trap heat and prevent it from escaping, making it suitable for creating insulation jackets that provide warmth and insulation.

- Q: Does fiberglass mat tissue provide good fire protection?

- No, fiberglass mat tissue does not provide good fire protection.

- Q: What are the properties of fiberglass mat tissue?

- Fiberglass mat tissue, also known as fiberglass mat or fiberglass matting, is a type of non-woven material made from glass fibers. It possesses several properties that make it suitable for various applications. 1. Strength and durability: Fiberglass mat tissue is known for its high tensile strength, which means it can withstand significant amounts of stress without breaking. This property makes it ideal for reinforcing and strengthening different materials and structures. 2. Lightweight: Despite its strength, fiberglass mat tissue is relatively lightweight, making it easy to handle and transport. This property is particularly advantageous in industries where weight reduction is important, such as aerospace and automotive. 3. Flexibility: Fiberglass mat tissue is flexible, which allows it to conform to curved surfaces and complex shapes. This property makes it versatile and suitable for applications where the material needs to be molded or formed into specific designs. 4. Chemical resistance: Fiberglass mat tissue has excellent resistance to various chemicals, including acids, alkalis, and most solvents. This property makes it suitable for applications in corrosive environments, such as chemical processing plants or storage tanks. 5. Thermal insulation: Fiberglass mat tissue has good thermal insulation properties, meaning it can help to reduce heat transfer. This property makes it useful in applications where heat insulation is required, such as in the construction of walls, roofs, or insulation boards. 6. Fire resistance: Fiberglass mat tissue is inherently fire-resistant and does not contribute to the spread of flames. This property makes it widely used in applications where fire safety is essential, such as in the production of fire-resistant doors, panels, or insulation materials. 7. Sound insulation: Fiberglass mat tissue also offers good sound insulation properties, reducing noise transmission through walls or other structures. This property makes it suitable for use in soundproofing applications, such as in recording studios or automotive interior panels. Overall, the properties of fiberglass mat tissue make it a versatile material with a wide range of applications in various industries, including construction, automotive, aerospace, and marine. Its strength, flexibility, lightweight, chemical resistance, thermal and sound insulation properties, as well as its fire resistance, contribute to its popularity and usefulness in many different applications.

- Q: How is fiberglass mat tissue used in the production of storage containers?

- The unique properties and benefits of fiberglass mat tissue make it a common choice in the production of storage containers. This thin layer of non-woven glass fibers offers excellent strength and durability, reinforcing the structure of the containers and ensuring they can withstand heavy loads without deforming. In addition to its strength, fiberglass mat tissue is highly resistant to corrosion, moisture, and chemicals. This makes it perfect for storage containers that may be exposed to harsh environments or contain corrosive substances. By acting as a protective barrier, the fiberglass mat tissue prevents any potential damage or degradation to the container. Furthermore, fiberglass mat tissue is lightweight, making it easier and more cost-effective to transport and handle during production. It also helps reduce the overall weight of the storage container, allowing for increased payload capacity and more efficient storage and transportation. During the molding process, the fiberglass mat tissue is typically applied to the surface of the container. It is often impregnated with a resin or adhesive, which, when cured, creates a strong bond with the container, enhancing its structural integrity. Overall, fiberglass mat tissue is crucial for the production of high-quality and long-lasting storage containers. Its strength, durability, corrosion resistance, and weight reduction capabilities make it the preferred choice for manufacturers in this industry.

- Q: Can fiberglass mat tissue be used for making insulation boards?

- Yes, fiberglass mat tissue can be used for making insulation boards. Fiberglass mat tissue is a lightweight, flexible material that is commonly used in the production of insulation boards. It provides excellent thermal insulation properties, as well as sound absorption and fire resistance. The mat tissue is typically layered and compressed to form the insulation boards, creating a durable and effective barrier against heat transfer. Additionally, fiberglass mat tissue is resistant to moisture, mold, and pests, making it a reliable choice for insulation applications. Overall, fiberglass mat tissue is a suitable material for making insulation boards due to its insulation performance, durability, and resistance to various environmental factors.

- Q: What are the different methods of bonding fiberglass mat tissue to other materials?

- There are various ways to bond fiberglass mat tissue to other materials, each with its own advantages and considerations. Some commonly used methods are as follows: 1. Mechanical Bonding: This technique involves physically interlocking the fiberglass mat tissue with the other material. It can be achieved through stitching, stapling, or using mechanical fasteners like screws or nails. While mechanical bonding provides a strong and durable connection, it may require additional hardware and can be time-consuming. 2. Adhesive Bonding: Adhesive bonding is a popular method that utilizes adhesives or glue to join the fiberglass mat tissue with the other material. This method offers flexibility, as there are different types of adhesives available for various applications. It is important to select an adhesive that is compatible with both the fiberglass mat tissue and the other material. Proper surface preparation and application techniques are crucial for achieving a strong bond. 3. Resin Infusion: Resin infusion involves infusing a liquid resin into the fiberglass mat tissue and other materials, resulting in a strong bond when cured. This method is commonly used in manufacturing composite products, as it allows for a seamless and uniform bond. Vacuum bagging or resin infusion techniques are typically employed to ensure proper resin distribution and consolidation. 4. Thermal Bonding: Thermal bonding employs heat to bond the fiberglass mat tissue to another material. This technique is particularly suitable for thermoplastic materials, as they can be softened and fused together with heat. Heat welding or ultrasonic welding are commonly used techniques for thermal bonding. Care must be taken to prevent damage or degradation of the fiberglass mat tissue during the bonding process. 5. Fusion Bonding: Fusion bonding is a method where the fiberglass mat tissue and the other material are heated to a molten state and then brought into contact to form a bond. This technique is commonly used in the manufacturing of thermosetting plastics or joining thermoplastic materials. Fusion bonding can provide a strong and seamless bond, but it requires precise control of temperature and pressure to ensure proper bonding without causing damage. To summarize, the various methods of bonding fiberglass mat tissue to other materials include mechanical bonding, adhesive bonding, resin infusion, thermal bonding, and fusion bonding. The choice of bonding method depends on factors such as the materials being bonded, the desired strength and durability, and the specific application requirements.

- Q: Can fiberglass mat tissue be used for making lightweight doors?

- Yes, fiberglass mat tissue can be used for making lightweight doors. Fiberglass mat tissue is a lightweight material that is commonly used in various industries for its strength and durability. It is made of thin strands of fiberglass that are bonded together with a binder, resulting in a strong and flexible material. When used in the construction of doors, fiberglass mat tissue offers several advantages. Firstly, it is lightweight, making it ideal for creating doors that are easy to handle and install. This can be particularly beneficial in residential or commercial settings where doors are frequently opened and closed. Additionally, fiberglass mat tissue possesses excellent thermal and acoustic insulation properties. This means that doors made with this material can effectively block out noise and regulate temperature, creating a more comfortable and energy-efficient environment. Furthermore, fiberglass mat tissue is resistant to moisture, rot, and insects, making it a durable and long-lasting option for door construction. It can withstand harsh weather conditions, making it suitable for both interior and exterior doors. Overall, fiberglass mat tissue is a versatile material that can be used to create lightweight doors that offer strength, durability, insulation, and resistance to various environmental factors.

Send your message to us

Fiberglass Mat Tissue Chopped Strand Mat for Boat Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords