Fiberglass Mat Tissue Fiberglass Surfacing Tissue

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 144000 Square Meter m²

- Supply Capability:

- 600000 Square Meter Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

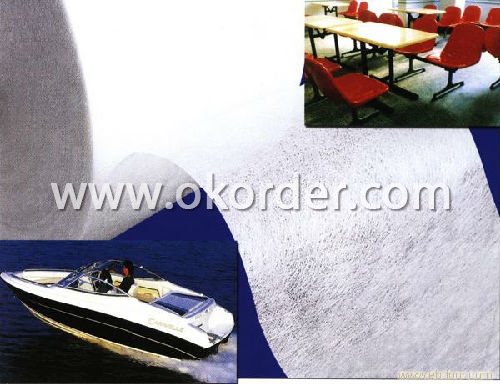

Introduction of Fiberglass surfacing tissue

Fiberglass surfacing tissue is mainly used for the surface layers of FRP products. It has good capability like fiber dispersion, smooth surface, low binder content, fast resin impregnation and good mould obedience. It is capable of significantly improving the strength of FRP surface layer, strong impaction resistance, excellent uniformity of surface, good covering up the texture of under layers and good corrosion resistance.

Specification of Fiberglass surfacing tissue

Size: 20g/, 30g/, 35g/, etc.

Width: 50mm, 75mm, 100mm, 1000mm, etc.

Length: 400m, 500m, 1000m, etc.

Product Characteristics of Fiberglass surfacing tissue

1.Uniform fiber dispersion

2.Smooth surface and soft hand-feeling

3.Low binder content

4.Fast resin impregnation

5.Good mould obedience

6.Good corrosion resistance

7.Strong impact resistance

- Q: How does the roll diameter of fiberglass mat tissue affect its handling?

- The handling of fiberglass mat tissue can be significantly impacted by the diameter of the roll. When the roll diameter is larger, the roll becomes heavier and bulkier, which poses a greater challenge for handling and maneuvering. This is especially important when the fiberglass mat tissue needs to be transported or installed manually. Furthermore, lifting and moving a larger roll diameter requires more physical effort, putting strain on those handling it. Additionally, larger roll diameters occupy more space, making storage and transportation more complicated. On the other hand, a smaller roll diameter makes the fiberglass mat tissue easier to handle due to its lighter and more compact nature. This is particularly advantageous in situations that involve frequent movement and installation, such as construction sites or manufacturing facilities. Moreover, a smaller roll diameter allows for more efficient storage and transportation as it takes up less space and can be easily stacked. This optimization of logistics helps minimize the costs associated with storage and transportation. In summary, the roll diameter of fiberglass mat tissue directly impacts its handling characteristics. Larger diameters make handling more challenging, while smaller diameters provide easier handling and improved storage efficiency.

- Q: What is the dimensional stability of fiberglass mat tissue?

- The dimensional stability of fiberglass mat tissue refers to its ability to maintain its size and shape under various conditions. Fiberglass mat tissue is known for its excellent dimensional stability, making it highly resistant to shrinking, expanding, or warping. This stability is achieved through the manufacturing process, which involves bonding glass fibers together using a binder material. This binder not only ensures the integrity of the mat tissue but also helps it maintain its dimensional stability over time. Additionally, the inherent properties of fiberglass, such as its high strength and stiffness, contribute to its exceptional dimensional stability. These characteristics make fiberglass mat tissue a popular choice in various applications, including construction, automotive, and aerospace industries, where consistent dimensions are crucial for optimal performance and durability.

- Q: Does fiberglass mat tissue provide good acoustical performance?

- Yes, fiberglass mat tissue does provide good acoustical performance. It has excellent sound absorption properties due to its fibrous composition, which helps reduce echo and improve overall sound quality in a given space.

- Q: What is the expected lifespan of fiberglass mat tissue?

- The expected lifespan of fiberglass mat tissue can vary depending on various factors such as the quality of the material, the environment it is exposed to, and how well it is maintained. However, on average, fiberglass mat tissue can have a lifespan of around 20 to 30 years.

- Q: Can fiberglass mat tissue be used for insulation boards?

- Yes, fiberglass mat tissue can be used for insulation boards. It is frequently utilized in insulation boards due to its excellent thermal and acoustic insulation properties. The fiberglass mat tissue helps to enhance the insulation capabilities of the boards, making them more energy-efficient and effective in reducing heat transfer and sound transmission.

- Q: What is the fire rating of fiberglass mat tissue?

- The fire rating of fiberglass mat tissue varies depending on its specific composition and the standards to which it has been tested. Fiberglass mat tissue is typically designed to have fire-resistant properties, but the exact fire rating will depend on factors such as the thickness of the tissue and any additional fire retardant coatings or treatments that have been applied to it. To determine the fire rating of a specific fiberglass mat tissue product, it is best to consult the manufacturer's specifications or test reports, as they will provide the most accurate and up-to-date information.

- Q: How is fiberglass mat tissue used in the production of composite panels?

- Due to its unique properties and versatility, fiberglass mat tissue is commonly utilized in the manufacturing of composite panels. Its role as a reinforcement material contributes to the enhancement of strength, durability, and overall performance of these panels. In the production process, a sandwich structure is typically formed by incorporating fiberglass mat tissue between layers of resin. This tissue serves as a reinforcing layer, providing added strength and stability to the panels. It effectively distributes applied stress evenly across the panel, thereby reducing the likelihood of cracks or fractures. One notable advantage of fiberglass mat tissue is its ability to enhance the impact resistance of composite panels. By absorbing and dispersing energy when subjected to external forces, it diminishes the risk of damage or breakage. This characteristic makes it a highly suitable choice for applications that necessitate high impact resistance, such as automotive parts, boat hulls, or aircraft components. Furthermore, fiberglass mat tissue exhibits excellent resistance to corrosion, making it appropriate for usage in environments with high humidity or exposure to chemicals. It acts as a protective barrier, shielding the composite panels from moisture and corrosive substances. As a result, the panels enjoy an extended lifespan and sustained performance. Moreover, fiberglass mat tissue possesses exceptional moldability, which facilitates the creation of intricate shapes and designs. It can be effortlessly molded into various forms, thus offering flexibility in the production process and enabling the fabrication of customized composite panels tailored for specific applications. In summary, fiberglass mat tissue is a vital component in the manufacturing of composite panels. It reinforces the structure, enhances impact resistance, improves corrosion resistance, and enables design flexibility. Its unique properties have made it a favored choice in industries such as construction, transportation, aerospace, and marine, where the demand for high-performance and long-lasting composite panels is prevalent.

- Q: What is the expected lifespan of fiberglass mat tissue in residential applications?

- The lifespan of fiberglass mat tissue in residential applications can differ based on various factors like material quality, installation process, and environmental conditions. On average, these tissues are designed to last approximately 20 to 30 years. Residential applications commonly utilize fiberglass mat tissues for reinforcement and strengthening, particularly in moisture-prone areas such as bathrooms, kitchens, and basements. They are renowned for their exceptional resistance to mold, mildew, and rot, making them a favored choice in these locations. Proper installation and maintenance of fiberglass mat tissues can provide lasting support and protection to underlying surfaces. However, it is essential to handle and install them correctly to avoid damage. Improper installation or exposure to extreme conditions like excessive heat or direct sunlight can significantly shorten their lifespan. Regular inspection and maintenance are crucial to ensure optimal performance and longevity of fiberglass mat tissues. This entails checking for signs of wear, tear, or water damage and promptly addressing any issues that arise. Periodic cleaning and sealing can also help extend the material's lifespan. In conclusion, while the typical lifespan of fiberglass mat tissue in residential applications is around 20 to 30 years, it is vital to consider factors such as quality, installation, and maintenance to ensure durability and longevity.

- Q: What is the tear strength of fiberglass mat tissue?

- The ability of fiberglass mat tissue to resist tears or cracks when exposed to external forces is referred to as its tear strength. This characteristic plays a crucial role in determining the durability and performance of fiberglass mat tissue in different applications. Standardized testing methods, such as the ASTM D1922 tear resistance test, are typically used to measure the tear strength of fiberglass mat tissue. This test involves applying a controlled force, usually in the form of a tensile load, to a sample of the material and measuring the amount of force required to cause a tear or rupture. The tear strength of fiberglass mat tissue can vary depending on factors such as the manufacturing process, the quality of the raw materials used, and the specific requirements of the application. Generally, fiberglass mat tissues are designed to have high tear strength in order to withstand the stresses and strains encountered during installation and use. Fiberglass mat tissue finds widespread use in industries like construction, automotive, aerospace, and marine, thanks to its high tear strength and other desirable properties. It is commonly employed as a reinforcement material in composites, providing increased strength and durability to the final product. In summary, the tear strength of fiberglass mat tissue is a vital property that determines its ability to resist tearing or cracking when subjected to applied forces. By ensuring a high tear strength, fiberglass mat tissue can meet the demands of various applications and deliver long-lasting performance.

- Q: Can fiberglass mat tissue be used for insulation in hot climates?

- Yes, fiberglass mat tissue can be used for insulation in hot climates. It has excellent thermal insulation properties and can effectively block heat transfer, making it suitable for use in hot climates to maintain cooler indoor temperatures.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2008 |

| Annual Output Value | Above US$20 Million |

| Main Markets | Mid East;Western Europe:South Asian |

| Company Certifications | ISO9001:2000;ISO14001:1996;GB/T28001:2001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 350 People |

| Language Spoken: | English;Chinese;Korean |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fiberglass Mat Tissue Fiberglass Surfacing Tissue

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 144000 Square Meter m²

- Supply Capability:

- 600000 Square Meter Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords