Fiberglass Mat Tissue - Fiberglass Woven Roving Compressed Mat, Density 900g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||

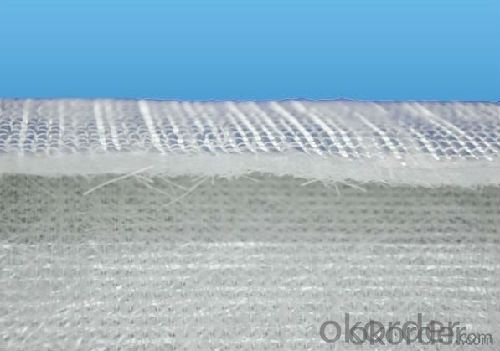

Fiberglass Stitch Combo Mat is a mat made by stitching together with woven roving and a layer of evenly distributed chopped strands.

It consists of two or more layers of fiber glass rovings which are stitch-bonded. one layer of rovings and differene layers of rovings can be oriented differently and have different linear density. the roving specification, number of roving layers, mat width and roll diameter can be customized as per requirement.

This product is widely used in hand lay-up and RTM processes. It is mostly widely used in boat industry, typical end-use application include FRP boat hulls, automotive shell and door, laminates, cooling apparatus and structural shapes. | |||||||||||||||||||||||||||||||||||||||

Product Traits: | |||||||||||||||||||||||||||||||||||||||

◎ Increase strength, reduce product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

FAQ

1. How can you guarantee the quality? We only provide the materials that have been approved by many customers and little claim or no claim on it. We have signed the obligation contract with the manufacturer. If the few quality issue happened, we can work with the manufacturer to solve it and customer’s benefit can be guaranteed.

2. Which delivery term will you usually offer? We usually offer FOB Chongqing, FOB Shenzhen, FOB Shanghai or CIF port (defined by the customer).

| |||||||||||||||||||||||||||||||||||||||

- Q: Can fiberglass mat tissue be used as a reinforcement in concrete?

- Yes, fiberglass mat tissue can be used as a reinforcement in concrete. Fiberglass mat tissue is a thin, lightweight material made from woven fiberglass strands. It is commonly used in construction and industrial applications due to its high strength and durability. When used as reinforcement in concrete, fiberglass mat tissue can help to increase the tensile strength and crack resistance of the concrete. It is typically applied in the form of a mesh or fabric, which is embedded within the concrete during the pouring process. The fiberglass strands in the mat tissue provide additional strength and reinforcement to the concrete, helping to prevent cracking and improve overall structural integrity. This can be particularly beneficial in areas where the concrete is subject to high loads, such as in bridges, concrete slabs, or precast concrete elements. Furthermore, fiberglass mat tissue is corrosion-resistant, which makes it a suitable choice for applications where the concrete is exposed to moisture or chemicals. It does not rust or degrade over time, unlike traditional steel reinforcement, which can help to extend the lifespan of the concrete structure. Overall, fiberglass mat tissue is a viable and effective reinforcement option for concrete. It offers enhanced strength, crack resistance, and corrosion resistance, making it a popular choice in various construction projects.

- Q: Does fiberglass mat tissue require any special surface bonding agents?

- Special surface bonding agents are necessary for fiberglass mat tissue. It is commonly used as a reinforcement material in industries like construction, automotive, and aerospace. To achieve a strong bond between the fiberglass mat tissue and the substrate, a suitable bonding agent or adhesive is needed. The bonding agent plays a crucial role in creating a durable and robust bond between the fiberglass mat tissue and the applied surface. It enhances the overall strength, integrity, and performance of the composite material. Additionally, it prevents delamination or separation of the fiberglass mat tissue from the substrate. The type of bonding agent required may vary depending on the specific application and the substrate's properties. Typically, epoxy-based bonding agents are widely used for bonding fiberglass mat tissue due to their excellent bonding strength, chemical resistance, and durability. Before applying the bonding agent, it is essential to thoroughly clean the surface and remove any contaminants that may affect adhesion. The bonding agent can then be applied using appropriate techniques such as brushing, spraying, or rolling. In conclusion, special surface bonding agents are necessary for fiberglass mat tissue to ensure proper adhesion and enhance the performance of the composite material. The choice of bonding agent depends on the specific application and substrate properties. Adequate surface preparation is also crucial for achieving a strong and durable bond.

- Q: Can fiberglass mat tissue be used for ceiling insulation?

- No, fiberglass mat tissue is not typically used for ceiling insulation. It is a material commonly used in the construction of composite materials, reinforcing plastic products, and for soundproofing purposes. Ceiling insulation is typically done using materials specifically designed for thermal and acoustic insulation, such as fiberglass batts, cellulose, or foam insulation boards.

- Q: How is fiberglass mat tissue used in the production of composite panels?

- Due to its unique properties and versatility, fiberglass mat tissue is commonly utilized in the manufacturing of composite panels. Its role as a reinforcement material contributes to the enhancement of strength, durability, and overall performance of these panels. In the production process, a sandwich structure is typically formed by incorporating fiberglass mat tissue between layers of resin. This tissue serves as a reinforcing layer, providing added strength and stability to the panels. It effectively distributes applied stress evenly across the panel, thereby reducing the likelihood of cracks or fractures. One notable advantage of fiberglass mat tissue is its ability to enhance the impact resistance of composite panels. By absorbing and dispersing energy when subjected to external forces, it diminishes the risk of damage or breakage. This characteristic makes it a highly suitable choice for applications that necessitate high impact resistance, such as automotive parts, boat hulls, or aircraft components. Furthermore, fiberglass mat tissue exhibits excellent resistance to corrosion, making it appropriate for usage in environments with high humidity or exposure to chemicals. It acts as a protective barrier, shielding the composite panels from moisture and corrosive substances. As a result, the panels enjoy an extended lifespan and sustained performance. Moreover, fiberglass mat tissue possesses exceptional moldability, which facilitates the creation of intricate shapes and designs. It can be effortlessly molded into various forms, thus offering flexibility in the production process and enabling the fabrication of customized composite panels tailored for specific applications. In summary, fiberglass mat tissue is a vital component in the manufacturing of composite panels. It reinforces the structure, enhances impact resistance, improves corrosion resistance, and enables design flexibility. Its unique properties have made it a favored choice in industries such as construction, transportation, aerospace, and marine, where the demand for high-performance and long-lasting composite panels is prevalent.

- Q: How does fiberglass mat tissue compare to polystyrene insulation?

- Fiberglass mat tissue and polystyrene insulation are two different materials with distinct properties and uses. Fiberglass mat tissue is a woven or non-woven fabric made from glass fibers. It is commonly used as a reinforcement material in various applications such as roofing, pipes, and automotive parts. Fiberglass mat tissue provides excellent strength, durability, and resistance to moisture and chemicals. On the other hand, polystyrene insulation refers to rigid foam boards or expanded polystyrene (EPS) beads used for thermal insulation purposes. Polystyrene insulation offers high thermal resistance, making it an effective material for insulating buildings and reducing energy consumption. Comparing the two, fiberglass mat tissue is primarily used for reinforcement and structural purposes, whereas polystyrene insulation is specifically designed for thermal insulation. The choice between them depends on the specific requirements of the application, such as the need for structural strength or thermal efficiency.

- Q: Can fiberglass mat tissue be used for repairing fiberglass jet skis?

- Yes, fiberglass mat tissue can be used for repairing fiberglass jet skis. Fiberglass mat tissue is commonly used in fiberglass repairs as it provides strength and reinforcement to the damaged area. It is a versatile material that can be used for various fiberglass repair applications, including repairing cracks or holes in jet skis. When applied properly, fiberglass mat tissue can help restore the structural integrity of the jet ski and ensure a durable and long-lasting repair.

- Q: How does fiberglass mat tissue compare to other types of reinforcement materials?

- Fiberglass mat tissue is a versatile reinforcement material that offers several advantages over other types of reinforcement materials. Firstly, it has excellent strength and stiffness properties, providing superior load-bearing capabilities compared to other materials. Secondly, fiberglass mat tissue is lightweight, making it easier to handle and install. Additionally, it is highly resistant to corrosion, chemicals, and moisture, ensuring long-term durability. Lastly, fiberglass mat tissue has excellent dimensional stability and is not prone to warping or shrinking, making it a reliable choice for various applications. Overall, its combination of strength, lightweight nature, durability, and dimensional stability sets fiberglass mat tissue apart from other reinforcement materials.

- Q: How does the width and length of fiberglass mat tissue affect its application?

- The width and length of fiberglass mat tissue can greatly affect its application in various ways. Firstly, the width of the mat tissue determines the coverage area and ease of installation. A wider mat tissue can cover a larger surface area, reducing the number of individual sheets required for a project. This can save time and effort during installation, especially for large-scale applications. Additionally, the width of the mat tissue can affect the overall strength and durability of the finished product. A wider mat tissue provides more reinforcement, making it suitable for applications that require greater strength and stability, such as in the construction of structural components or high-stress areas. On the other hand, the length of the mat tissue impacts the convenience and flexibility during application. Longer rolls of mat tissue allow for continuous installation without the need for frequent seams or joints. This is particularly advantageous when working on large projects, as it minimizes potential weak points and enhances the overall integrity of the fiberglass application. Moreover, the length of the mat tissue also affects the ease of handling and transportation. Longer rolls can be more challenging to maneuver and transport, especially in confined spaces or through narrow doorways. Therefore, the length should be considered based on the accessibility and logistics of the specific application site. In summary, the width and length of fiberglass mat tissue play crucial roles in its application. The width determines the coverage area, strength, and durability, while the length influences the convenience, flexibility, and handling during installation. Considering these factors allows for a more efficient and successful application of fiberglass mat tissue in various industries and projects.

- Q: Is the Teflon gasket filled with fiberglass or graphite?

- PTFE itself has the effect of self lubrication, you can ask the production of PTFE can add these, should not be able to! Vespel can add graphite to increase self lubrication

- Q: What are the potential health and safety concerns associated with working with fiberglass mat tissue?

- Working with fiberglass mat tissue can pose several potential health and safety concerns. Firstly, fiberglass contains tiny glass fibers that can become airborne when the material is cut, sanded, or disturbed. Inhalation of these fibers can lead to respiratory problems such as coughing, wheezing, and difficulty breathing. Prolonged exposure to fiberglass dust may also cause lung diseases like fibrosis or even lung cancer. Additionally, direct contact with fiberglass mat tissue can irritate the skin, leading to itching, redness, and rashes. The sharp edges of the glass fibers can cause tiny cuts or punctures, which may become infected if not properly treated. Moreover, fiberglass is a lightweight material that can easily become airborne and settle on surfaces, increasing the risk of ingestion or contamination of food and drinks. Ingesting fiberglass particles can irritate the digestive system, causing nausea, vomiting, and abdominal pain. To ensure the health and safety of workers, proper precautions should be taken when working with fiberglass mat tissue. This includes wearing personal protective equipment such as gloves, safety glasses, and respiratory masks to minimize exposure to airborne fibers. Adequate ventilation and dust control measures should also be in place to prevent the accumulation of fiberglass dust in the work area. Regular cleaning and maintenance should be performed to keep the work environment free from fiberglass particles. Workers should be educated on the proper handling and disposal of fiberglass materials to minimize the risk of contamination. Overall, while fiberglass mat tissue is a widely used material, it is important to be aware of the potential health and safety concerns associated with its handling and take necessary precautions to minimize the risk of exposure.

Send your message to us

Fiberglass Mat Tissue - Fiberglass Woven Roving Compressed Mat, Density 900g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords