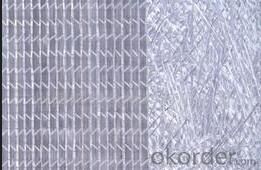

Fiberglass Mat Tissue Woven Roving Combo Mat 900gsm,1600/2400

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Process

Fiberglass stitch combo mat is the mat combining the woven roving and a even layer of chopped strand mat with polyester yarn.

Properties

• Fiber level unfolded without cross, high density, high utilizing rate.

• Multi-layer finished one time, decrease layer and enhance efficiency.

• Providing the product with multi-directional mechanical strength.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Specifications

specifications | Fibre type | Wover roving | Chopped strand | Overall weight | Width |

(g/㎡) | (g/㎡) | (g/㎡) | (mm) | ||

EMK 600/300 | E-Glass | 600 | 300 | 900 | 1600/2400 |

EMK 600/380 | E-Glass | 600 | 380 | 980 | 1600/2400 |

EMK 600/450 | E-Glass | 600 | 450 | 1050 | 1600/2400 |

EMK 800/300 | E-Glass | 800 | 300 | 1100 | 1600/2400 |

EMK 800/380 | E-Glass | 800 | 380 | 1180 | 1600/2400 |

EMK 800/450 | E-Glass | 800 | 450 | 1250 | 1600/2400 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||||

- Q: What are the different reinforcement orientations available for fiberglass mat tissue?

- There are several different reinforcement orientations available for fiberglass mat tissue, each serving a specific purpose in various applications. One common orientation is the unidirectional reinforcement, where the fibers are aligned in one direction. This orientation provides high strength and stiffness in the direction of alignment, making it suitable for applications that require resistance to tension or bending forces in a single direction. Another orientation is the bidirectional reinforcement, where the fibers are aligned in two perpendicular directions. This orientation provides equal strength and stiffness in both directions, making it ideal for applications that require resistance to both tension and compression forces. Bidirectional reinforcement is commonly used in structural components such as panels, pipes, and tanks. A third orientation is the randomly oriented reinforcement, where the fibers are distributed in a random manner. This orientation offers isotropic properties, meaning it provides similar strength and stiffness in all directions. Random reinforcement is often used in applications that require uniform strength and flexibility, such as automotive parts, boat hulls, and sporting goods. Additionally, there are also hybrid reinforcement orientations available, which combine different types of fibers or orientations to achieve specific performance requirements. These hybrid reinforcements can offer a combination of strength, stiffness, flexibility, and other desired properties, making them suitable for a wide range of applications. Overall, the choice of reinforcement orientation for fiberglass mat tissue depends on the specific requirements of the application, including the desired mechanical properties, the direction of forces to be resisted, and other performance considerations.

- Q: Are there any environmental considerations when using fiberglass mat tissue?

- Yes, there are several environmental considerations when using fiberglass mat tissue. Firstly, the production of fiberglass mat tissue involves the extraction and processing of raw materials, which can have a negative impact on ecosystems and contribute to air and water pollution. Additionally, fiberglass mat tissue is not biodegradable and can contribute to landfill waste if not properly disposed of. Furthermore, the manufacturing process of fiberglass mat tissue usually requires significant energy consumption, which can contribute to greenhouse gas emissions and climate change. Therefore, it is important to consider and implement sustainable practices when using fiberglass mat tissue to minimize its environmental impact.

- Q: How does fiberglass mat tissue compare to other types of insulation materials?

- Fiberglass mat tissue is a type of insulation material that has its own unique characteristics and advantages when compared to other insulation materials. Firstly, fiberglass mat tissue is known for its excellent thermal insulation properties. It has a low thermal conductivity, meaning it effectively reduces the transfer of heat between the inside and outside of a building. This helps to keep buildings cooler in the summer and warmer in the winter, leading to energy savings and increased comfort. In addition to its thermal insulation capabilities, fiberglass mat tissue also offers excellent sound insulation. It helps to reduce noise transmission through walls and floors, creating a quieter and more peaceful indoor environment. This is particularly beneficial in commercial buildings, where noise reduction is important for productivity and customer satisfaction. Furthermore, fiberglass mat tissue is a lightweight and flexible material, making it easy to handle and install. It can be easily cut to fit around obstacles such as pipes and ducts, ensuring a tight and efficient insulation barrier. This ease of installation saves time and labor costs during construction or renovation projects. Another advantage of fiberglass mat tissue is its fire resistance. It is a non-combustible material, meaning it does not contribute to the spread of fire. This is especially crucial in buildings where fire safety is a top priority, such as hospitals, schools, and residential properties. Moreover, fiberglass mat tissue is durable and long-lasting. It does not degrade or lose its insulation properties over time, ensuring consistent energy efficiency and performance for many years. This durability makes it a cost-effective insulation choice, as it reduces the need for frequent replacement or maintenance. Lastly, fiberglass mat tissue is environmentally friendly. It is made from recycled glass and sand, which reduces the demand for raw materials. Additionally, it is recyclable at the end of its lifespan, further reducing waste and promoting sustainability. Overall, fiberglass mat tissue offers excellent thermal and sound insulation, ease of installation, fire resistance, durability, and environmental benefits. While other insulation materials may have their own advantages, fiberglass mat tissue is a versatile and reliable option for various applications.

- Q: Can fiberglass mat tissue be used for insulation boards?

- Insulation boards can indeed utilize fiberglass mat tissue as a viable option. This lightweight and flexible material consists of delicate glass fibers melded together with a resin. Its outstanding thermal insulation qualities make it an optimal selection for insulation boards. The mat tissue is effortlessly customizable, capable of conforming to various shapes and sizes, thereby facilitating insulation of walls, roofs, floors, and other areas within a structure. Notably, it possesses resistance against moisture, mold, and mildew, ensuring enduring insulation performance. Moreover, fiberglass mat tissue exhibits fire-resistant properties, further bolstering its suitability for insulation applications. In summary, fiberglass mat tissue proves to be an adaptable and efficient material for insulation boards.

- Q: Does fiberglass mat tissue require any special tools for installation?

- Special tools may be needed for installing fiberglass mat tissue. These tools may include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment like gloves and goggles to protect the installer from potential dangers. Furthermore, certain installations may necessitate the use of a heat gun or torch to activate or cure the resin. To ensure proper installation and ascertain if any special tools are necessary, it is crucial to carefully read and adhere to the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used.

- Q: Can fiberglass mat tissue be used for acoustic panels?

- Yes, fiberglass mat tissue can be used for acoustic panels. Fiberglass mat tissue is a lightweight material that is commonly used for sound absorption and insulation purposes. It has excellent sound-absorbing properties and can effectively reduce noise levels in various applications, including acoustic panels. It is often used as the core material in acoustic panels to enhance their sound-absorbing capabilities. Additionally, fiberglass mat tissue is easy to work with, making it a popular choice for DIY acoustic panel projects. However, it is important to note that the effectiveness of acoustic panels also depends on other factors such as panel design, thickness, density, and installation method. Therefore, it is recommended to consult with experts or conduct thorough research to ensure that fiberglass mat tissue is the appropriate material for your specific acoustic panel needs.

- Q: What about high temperature fiberglass?

- The glass will not melt at this temperature, but the silica gel may soften. Glass fiber may break, preferably not for direct contact with food, and may enter the body

- Q: Can fiberglass mat tissue be used for reinforcement in composites?

- Fiberglass mat tissue, composed of glass fibers randomly arranged, can reinforce composites. It is frequently utilized in the manufacturing of composites to enhance their strength. By combining the mat tissue with resin, a sturdy and durable composite material can be created. The random orientation of the fibers contributes to the composite structure's strength and reinforcement in multiple directions. Moreover, the mat tissue's flexibility allows for easy layering and molding into intricate shapes, making it suitable for a range of applications in industries like automotive, aerospace, construction, and marine. In conclusion, fiberglass mat tissue is extensively employed and highly effective as a reinforcement material in composites.

- Q: What is the chemical resistance of fiberglass mat tissue?

- Fiberglass mat tissue exhibits excellent chemical resistance due to the inherent properties of the fiberglass material. The mat tissue is typically composed of glass fibers that are woven or bound together, providing a barrier against a wide range of chemicals. The glass fibers themselves are highly resistant to corrosion, making fiberglass mat tissue suitable for use in environments where exposure to chemicals is a concern. The chemical resistance of fiberglass mat tissue can vary depending on the specific resin or binder used in the manufacturing process. Different types of resins may provide enhanced resistance to certain chemicals, while others may be more susceptible to degradation. It is important to consider the specific chemicals that will come into contact with the fiberglass mat tissue and select a resin or binder that is compatible with those substances. In general, fiberglass mat tissue is known for its resistance to acids, alkalis, solvents, and many other chemicals commonly found in industrial and commercial settings. It can withstand exposure to a wide range of corrosive substances, making it a versatile and durable material for various applications. However, it is worth noting that prolonged exposure to highly concentrated or aggressive chemicals may eventually cause some degradation or deterioration of the fiberglass mat tissue. Therefore, it is essential to consult the manufacturer's specifications and guidelines to ensure proper chemical compatibility and performance in specific environments.

- Q: Can fiberglass mat tissue be used for insulation in cleanrooms?

- Fiberglass mat tissue can indeed be used for insulation in cleanrooms. It offers several advantages that make it a suitable choice for such applications. Firstly, fiberglass mat tissue has excellent thermal insulation properties, which helps to maintain the desired temperature and prevent heat transfer in cleanrooms. This is crucial in environments where temperature control is essential for processes or equipment. Additionally, fiberglass mat tissue has good acoustic insulation capabilities, which can help in reducing noise levels within cleanrooms. This is particularly important in cleanrooms where sensitive equipment or experiments are conducted, as minimizing noise disturbances can ensure accurate and reliable results. Furthermore, fiberglass mat tissue is non-combustible, meaning it does not catch fire easily. This adds an extra layer of safety in cleanrooms where flammable materials or volatile substances may be present. The non-combustible nature of fiberglass mat tissue also contributes to its overall durability and longevity. Lastly, fiberglass mat tissue is resistant to moisture, making it suitable for cleanrooms where humidity control is crucial. It does not absorb moisture, preventing the growth of mold or mildew, which can be detrimental to cleanroom environments. Overall, fiberglass mat tissue is a viable option for insulation in cleanrooms due to its thermal and acoustic insulation properties, non-combustible nature, and resistance to moisture. Its use can contribute to maintaining the desired conditions within cleanrooms and ensuring the integrity of processes and equipment.

Send your message to us

Fiberglass Mat Tissue Woven Roving Combo Mat 900gsm,1600/2400

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords