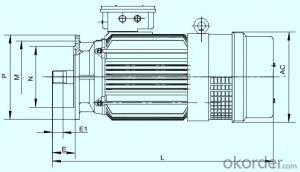

YTRVF(W)Variable一Frequency Three-Phase Asynchronous Stewing Motor for Tower Crane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview

This series motor is a variable-frequency three-phase asynchronous motor exclusively designed for tower cranes and other similar dewing mechanisms. It is applied to the dewing

mechanisms in very harsh working conditions such as construction site or open pit quarry.

Features

With introduction of spline drive shaft, it has good mechanical bearing capacity;

The motor is a variable-frequency motor featuring a wide range of speed regulation, high efficiency, small starting current, big starting torque and overload ability;

A thermal protection component is buried into the in winding, making motor more safer and reliable;

Excellent dedicated variable-frequency insulation materials are adopted, improving greatly the insulation reliability;

Compact structure, small volume, lightweight, so it can be braked quickly and positioned accurately. It is suitable for frequent starting and braking;

YTRVFW series motor is provided with an eddy current brake on the basis of YTRVF series. It enables more smooth starting and deceleration braking, making the operation

more smooth and accurate

Users’Options:

This series motor is divided into F1 and F2

F1 with airvane brake;will be determined by the

F2 without airvane brake;users when signing the contract but an encoder interface can be reserved

- Q: Is it ok to leave the heater in the quot;on positionquot; even after I turn my car off? Will it cause any damage to the blower motor, if every time I turn on my car; the heater turns on automatically because it's in the quot;on positionquot;?

- Yes, it is not getting any power while the car is off.

- Q: What is the difference between the excitation winding and armature winding of AC motor?

- Only synchronous generator and synchronous motor have excitation winding and armature winding. In general, AC induction motors do not have field windings. The asynchronous motor is divided into two major categories, squirrel cage and winding. The stator winding structure is the same. The squirrel cage rotor is a squirrel cage, and the winding rotor is a coil (which can be changed by an external device to change the rotor impedance).

- Q: Why is DC motor wider than AC motor? High speed regulation accuracy? How do you know?

- The DC motor has the ability to keep the rated torque from the zero speed to the nominal speed, so it can perform stepless speed regulation from zero speed to rated speed (constant torque).

- Q: How do ordinary AC motors brake?

- Reverse brakingWhen the motor cuts off the normal power supply, the power phase sequence of the motor stator winding is changed so that a reverse braking torque is generated.

- Q: How are normally AC motors reversed?

- it depends on whether it is a three phase or single phase motor you are talking about. in 3 phase all that is needed is to swap 2 of the power legs to induce a reverse rotation. EX. (phase a , phase b , phase c) to reverse==> (phase a , phase c , phase b) or any other combination {only swap 2, if you swap all 3 you defeat the change in the magnetic fields and it spins the same. on a single phase motor, it has to have the ability to have access to it's winding wires (most small horsepower motors don't have this function) ac motors are designed for ac power, not to have there power signal changed to dc. if you change the power to dc, then you need a dc motor...

- Q: What is the difference between stepping motor and servo motor and three-phase asynchronous motor? What are the advantages of their differences?

- Stepper motor principle: stepper motor is a kind of electric pulse into angular displacement of the implementation of the mechanism. Generally speaking, when the stepping driver receives a pulse signal, it drives the stepper motor to rotate a fixed angle (and step angle) in the set direction. We can control the angular displacement by controlling the number of pulses, so as to achieve the purpose of accurate positioning. At the same time, we can control the speed and acceleration of motor rotation by controlling the pulse frequency, so as to achieve the purpose of speed regulation.Advantages: as a digital input, the motor accuracy has been greatly improved, speed and acceleration control is easy to achieve, and the control effect is better.

- Q: what are the two types of motors that are for a single phase multi-speed applications?

- 1--- A shaded-pole motor is a type of AC single-phase induction motor and needs a triac speed control to give multi speeds 2----A synchronous electric motor is an AC motor distinguished by a rotor spinning with coils passing magnets at the same rate as the alternating current and resulting magnetic field which drives it.

- Q: I have to do research for an engineering project and i can't even figure out what it ishelp!

- A motor that runs on alternating current as opposed to direct current. There are several types, also things like drills tend to have universal motors that will run on either.

- Q: Here's the issue - Fan won't work at all unless it is on THE very highest setting. If I turn the heater on (with the fan at the highest setting), the heater works. The AC does not. If it is the blower motor, why does the fan at least work on the highest setting? And if it's the AC, why does the fan not work at any of the lower settings? I'm bewildered. What is wrong with my car? The only thing I do know is I'm roasting...

- 1. blower motor could be bad. 2. rheostat could be bad. ac: does the compressor come on? does it turn off and on every three seconds. then it is low on freon. i think what the other kid was saying is that his father charged the ac system every two years. you may be dealing with two different issues.

- Q: Comparison of AC motor and direct current motor

- Disadvantages of DC motor1. direct current motor manufacturing is more expensive2. carbon brush

Send your message to us

YTRVF(W)Variable一Frequency Three-Phase Asynchronous Stewing Motor for Tower Crane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches