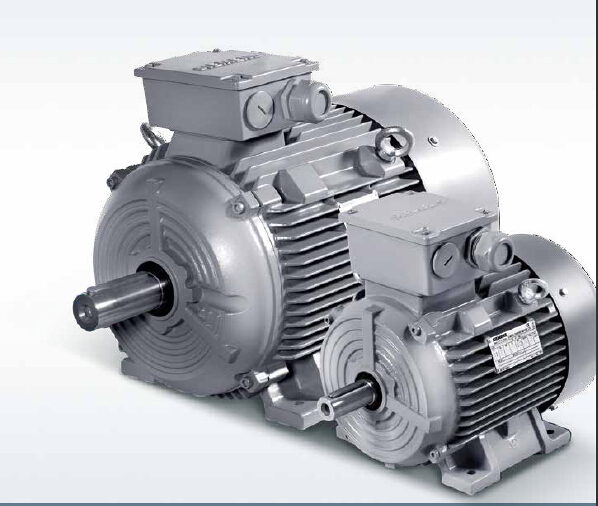

Siemens 1PQ Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: my AC motor have 2800 rpm but i need 1500 to 1800 rpm which will be variable value.i can control rpm my self 1500 to 1800 which i need.how can i do this?and is this effect on life of motor?

- you can get tapered belt drives to do this,or electronic speed controllers ,little or no effect on the motor

- Q: Specifically, what happens if I put AC electricity in a DC brush-less CPU fan? I read some where that DC brush-less motors are like AC motors.

- They don't, really. Perhaps you are thinking of the voltage. Generally, DC motors use a lower voltage than AC motors. This is due to the physical properties of electricity and how we transport electricity around a city. The energy used by a motor does not depend on whether the electricity is AC or DC. But the type of electricity, AC or DC, determines how the motor works.

- Q: What's the difference between asynchronous and synchronous AC motors?

- The induction motor is realized by induction. The principle is that in the stator winding with three-phase voltage, will form a rotating magnetic field, the rotor on the lead because of cutting lines of force, so the potential, and because the guide bar is connected, so produce the current. At this point, we think of what we learned in junior high school -- "electrified conductors produce motion in a magnetic field."". So this kind of motor is called induction motor". For asynchronous or induction machines, the number of poles of the rotor is automatically induced by the number of poles of the stator. It can also be said that the rotor is not polar. (above is an example of armature winding on the stator). There is no pivot / transition for asynchronous motors.

- Q: I check with our supplier. they told me that we have to load on motor then only it will show correct rpm ( both low and high). what is the maximum load for this motor It is shoiwng 1.3 amp

- DOES THE MOTOR HAVE A 2 SPEED switch, and what are you using it for? 1.3 amps has to be 120 volt. its probably a 2 speed motor without a switch. in that case it has to be under a load. if this helps you cant hear it change speeds, even under a load, i really need more info before i can help you. how are you checking the rpms? butch

- Q: what should i do to make it really fast?use more magnets? how do i reduce friction?how many coils?thanks!!!!

- Welcome to the the World of Electric Motors. How to Builda 2 Amp Motor, a step at a time. Coiling, position of Magnet (Type of Magnets), choice of Bushing and bearings, all play a integral part of making either a High torque or in this case RPM motor. Assuming that you are operating a DC Motor, (AC Motor, don't usually use magnets, but there are some out there) Start with Basic Design Link 1. - Answer you question about number of magnet (More accurately the Magnet strength) - And the Number of Coils Request for Speed Link 2. Summary For Speed, usually requires a lot of coils, generating a rapidly changing field, expect a few armature and alot of sections of magnets. Note 2 Ampere is al lot of current, and can easily harm any careless person. Check several time, visually and with the proper equipment before energizing the equipment. Friction reduction is a complete science by itself. If it is a School project, consider Dry type of Lub such as Graphite Carbon. As the running duration is short. (tens of minutes runs, with long period of down time that allow inspection) If it need a longer running time is expect, consider commercial grade stuff, such as Air bearings.

- Q: It is the chiller plant pump and we were trying to run the pump,unfortunately the motor was damaged.so what could have happened to this motor.

- If the motor is filled with water, don't run it. Disassemble the motor and oven bake until the moisture is evaporated. If the motor is immersed while operating, the motor may be burnt. Megger test between line to ground and between two lines. If the insulation resistance is below 1 megohm, the motor may be burnt.

- Q: What about the capacitance of the AC motor?

- If the capacity is constant (refer to kvar), the pressure will decreaseIf the pressure level has not changed, the capacitance is too large, no problemCapacitor selection depends mainly on voltage and capacity, while the capacitance is proportional to the capacity and inversely proportional to the square of the voltageYou also have an understanding of the problem, the capacitor in question is that the capacitor is too large, only the capacity is too largeIf this is the case, the capacitance will be reduced when the voltage level is constant. The larger is undesirable, but as a matter of fact, the assembly will cause damage to the capacitor

- Q: Explain why a motor must use a commutator if only DC current is supplied.

- an AC motor can operate on oscillating electromagnetic fields which induce currents in coiled wire. DC motors not not operate with such induced fields. Instead they must create therir own oscillating fields in the coils and this is done by rapidly switching the current on and off. This switching is done by means of the comutator and the split electrodes on the shaft...Hope this helps...

- Q: An AC motor is supposed to be a constant power motor. Suppose it is running a constant torque load at a particular speed. Suppose now the voltage is reduced, which should cause it to settle down at a lower speed supplying the same torque as per the new torque speed characteristic. Consider the electrical side. Higher slip will cause more current to be drawn that too at higher pf, which should maintain the power justifying the above theory. But on the mechanical side the new output power Torque x speed is supposed to be lesser now as speed is less now. Could anyone explain this contradiction?

- An AC motor is more a constant speed motor, tied nominally to the mains frequency. The slip induced by the load increases the current drawn the force generated. Lowering the voltage will increase the slip current until a new equilibrium is reached. That is why a brownout is BAD for AC motors as they quickly overheat

- Q: I've got a motor off of a Sears air compressor. I found one cap is bad, and the other missing. The ohm reading on circuit with bad cap is 0.8 and 1.4 ohms for circuit with missing cap. So how do i figure what value of cap to get for the missing capacitor? I am trying to fix this for a guy from work. He was as usual not listening to my advice and was buying capacitors to replace the missing one. They all burned up. I'm sure he had no idea what size to get. But what i wonder is if the start cap is bad would that cause the other to burn out? I'm thinking the circuit with the lower ohm value is the starting windings. Am i right or backwards.

- Check ohms to the frame of the motor before you buy anything to make sure the windings aren't grounded. The start winding is the one with the higher resistance to common. The motor should have a plate or tag on it telling you what size capacitor to use. You might try calling sears repair center for the correct run capacitor to install. Most psc motors won't use 2 capacitors, as they use a centrifugal switch inside the motor to disable the start winding once rpms are up. BTW, psc means Permanent Split Capacitor.

Send your message to us

Siemens 1PQ Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords