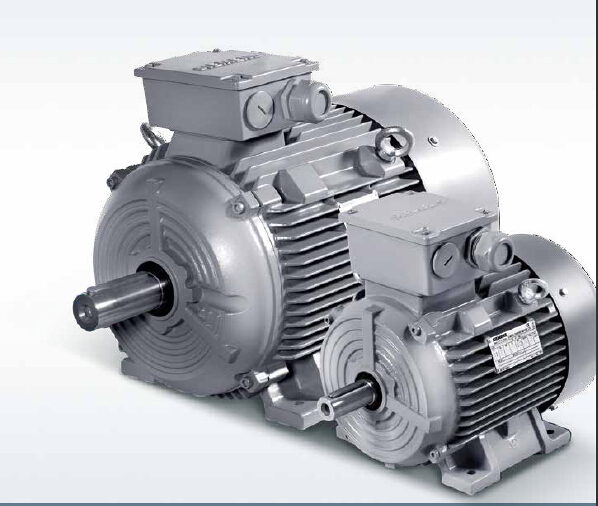

Siemens ILE0001 Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Is this the part that controls wether i get cold or hot air? Please give lots of detail about the location of this part.Thanks

- Yes it controls the blend door inside the plynum so its called a blend door acuator.Its either a acuator motor or vacuum controled diaphram thats located in the plynum,basically the giant plastic box mounted inbetween the dash and fire wall near the heater core.Would have to rip up the dash to get to,and would be a good idea to get a chiltons or take it into a shop, its a big job..GL

- Q: I check with our supplier. they told me that we have to load on motor then only it will show correct rpm ( both low and high). what is the maximum load for this motor It is shoiwng 1.3 amp

- The motor that you have must be a shaded pole motor with a “full-torque” connection and a “reduced-torque” connection. With either connection, the motor will run at nearly 1200 RPM (assuming 60 Hz) when it has no load. The load causes the motor speed to be reduced below 1200 RPM. With the “reduced-torque” connection, the load has more effect and the motor runs at a slower speed. The motor is designed to drive a fan. Fans have the characteristic that the torque required to drive them at any given speed is proportional to the square of the speed. A fan that requires 1/3 Hp at 1070 RPM would require 0.33 X 5252 /1070 = 1.64 lbs-ft of torque at 1070 RPM. At 800 RPM, the fan would require 1.64 X 800^2 / 1070^2 = 0.91 lbs-ft of torque. The horsepower required at 800 RPM would be 0.91 X 800 / 5252 = 0.14 Hp. The operating speed of the motor depends on the torque vs speed characteristic curves of the motor for the two connections intersecting the torque vs speed characteristic curve of the fan at the desired speeds. If it is the proper motor for the fan and the restriction of air flow corresponds to the design, the motor should operate at the design speeds. With any AC motor and particularly with this type of motor, it is difficult to estimate load from current. This type of motor is very inefficient. Even if you measure power, it will be difficult to estimate load.

- Q: Soybean milk machine AC motor or DC motor is good?

- With a special fragrance, and slightly stimulated; slightly sweet, and accompanied by stimulating spicy taste. Flammable gas whose vapors can form explosive mixtures with air and can be miscible with water at any rate.

- Q: I have a single phase AC motor of 1440 rpm that i can reduce upto 20rpm by gear arrangement pl help me by saying gear sizes.................

- 20 Rpm Motor

- Q: When a small AC motor is operating at rated load from a 115V, 60-cycle source, it takes 287 watts at a lagging power factor of 0.6. a. Calculate the line current. b. What should be the capacitance of the capacitor connected in parallel with the motor that will make the power factor unity?. c. Determine the line current under this condition?

- Power, p = 287 watts, power factor 0.6(lagging 53.1°) volts, v = 115 volts, 1.) line current, IL = 287/115 = 2.5 Amps 53.1° lagging >==================< ANSWER 2.) Impedance, |z| = (115)^2/287 = 46.1 ohms, OR, z = 46.1(cos53.1° - j.sin53.1°), SO, Reactance, XL = -46.1*sin(53.1) = 36.86 ohms, For unity power factor, Capacitor C ?F is connected, SO, 1/2pi f C = 36.86, ===> C = 1/2pi*60*36.86 = 0.72 ?F >===============< ANSWER

- Q: I was just wondering what the 3 wire connected to. is there anyway to run that motor without the control system (or the circut board that i cannot remember the name of at the moment) that attaches to the battery.thanks, if you have any diagrams that would get you a best answer!!thanks again

- These motors will not work without the control board. The motor is actually a 3 phase AC motor, the control board provides the battery conversion to 3 phase, and varies the supply frequency for speed control. So each wire is connected to a separate winding in the motor. I don't know whether the windings are connected in a star or delta configuration, though. Maybe either might be used. There are brushless DC motors about, but generally only low power ones. They only have 2 wires. The necessary switching functions usually done by carbon or metal brushes, are done by internal electronics instead. They are common in motors such as computer fans.

- Q: How is the rated current of three-phase AC motor calculated?

- Rated current (1.732 In=Pn/ * Un * n * cos Phi ETA).Where Pn is the nominal rated power, rated voltage Un, COS with n rated power factor, rated efficiency.Note that the power refers to the power output shaft, Pn/ is the input electric power.

- Q: When more poles are added to an AC synchronous motor, the speed is decreased according to:RPM = 120 x f / n where n is the (even) number of poles and f is the frequency in Hz.I can find plenty of sources stating this effect, but nowhere can I find an explanation on why (ie: the physical mechanism), explicitly anyways, the number of poles slows down the speed. Also, where the 120 constant derived from and what are it's units (or is it non-dimensional)?Thanks

- basically it is because you only rotate the amount the poles are separated for each cycle. double the poles, you rotate 1/2 has slow. the motor will run smoother, though.

- Q: I am replacing a fan motor in my AC unit. I have few questions. First of all, the wire that comes with motor is not in sufficient length to connect to the connector, How can I extend those wires? Secondly, The fan motor suggests to use only 340 V two prong small condenser, but the original condenser have 3 prong connection. So, Do I need to connect the small one along with the original one? Also, previous motor has only 3 wires *black, purple and brown) but the new motor has 4 wires (brown, brown-white, yellow and black). So, I am confused. Any help would be greatly appreciated.

- I know exactly the motor you have with the brown/black/purple....be sure the shaft size /amp draw/ and rpm are a correct match or compatible..I will answer you/but you really need to get a tech out there(seriously)...if you have a four wire condensor motor...the two brown wires will go directly to its own run capacitor/don't rehook to the dual run capacitor in the unit/it will make life easier on you.all you have now is line voltage to hook up.look at the top of your contractor.there is no polarity on 230 single phase.take your yellow or white(motor power lead and go to one side(t-1) and then black will be opposite (t-2)...if you have a heat pump this will be fed off odf on the defrost Board. If its got a yellow and a orange small set of plugs they are your rotation plugs.also make sure you set your depth on your blade....and reomove moisture plug...good luck be careful.

- Q: what is the difference between a dc motor and an ac motor?

- An induction motor uses a shorted rotor, and gets it's drive current to create the repulsion needed to make it turn. A DC motor is built to create the repulsion needed by virtue of the configuration of how the electromagnets are oriented in the motor. The problem with your question is that in a universal motor, it will run off of either AC, or DC voltage because it uses a commutator.

Send your message to us

Siemens ILE0001 Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords