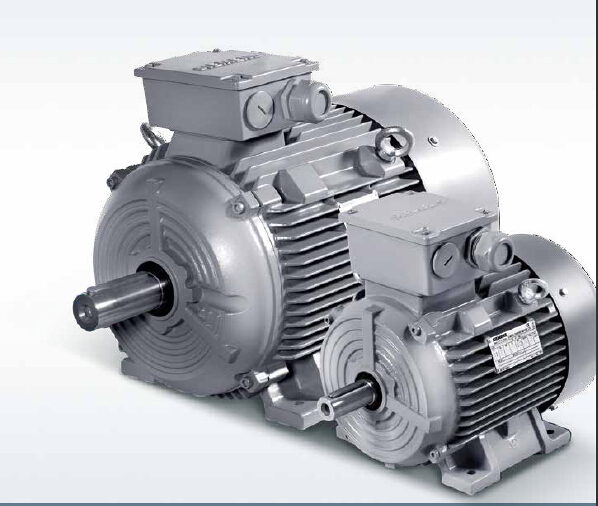

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: on my previous question quot;Are there Unordinary AC motors out there ?quot;, VShade said that:Mechanical Power (watts) = Torque (newton-meters) X Speed (RPM) / 9549.

- My previous answer should have been: Mechanical Power (kilowatts) = Torque (newton-meters) X Speed (RPM) / 9549 or Mechanical Power (watts) = Torque (newton-meters) X Speed (RPM) / 9.549 Using the correct units/decimal location Power at peak torque = 55 X 500 / 9.549 = 2880 watts Torque at rated power = 735 X 9.549 / 500 = 14 N-m Torque for 1500 RPM connection = 2035 X 9.549 / 1500 = 12.95 N-m

- Q: There is no magnets in an induction motor so is this even possible.

- No, given which you furnish a source of three area capability to energise the sphere windings. with out that, you purely have some coils of cord spinning close to different coils of cord. No magnetic fields, no capability generated.

- Q: Tore an AC motor out of an OLD SCHOOL cassette tape changer. It has three leads, red, blue, yellow... Tried all conbonations with a 120v whip. Some did nothing others made it humm... That's about it... Wondering how I can find out how to drive this baby???

- ya motor could very well be a stepping motor run by a chip that supplies a pulsed supply around the 3 wires which it reverses by reversing the pulses similar to a lightchaser if you wish to go into this further try googling this chip- SAA 1027

- Q: Distinct Between Synchronous Asynchronous Alternators AC Motors

- Generators of both types of have an even number p of magnetic poles, ie p = 2, 4, 6,.. etc.. The synchronous speed of both types is equal to 3600 x 2/p on a 60 Hz system and 3000 x 2/p on a 50 Hz system. Synchronous generators run at exactly their synchronous speed corresponding to the pole number and supply frequency. Asynchronous generators run slightly faster than their synchronous speed. The design distinction between the two is that the synchronous generator (or alternator or turbogenerator) has a field winding on its rotor which is supplied with DC from an external source to magnetise the machine. The asynchronous (or induction) generator has a short-circuited rotor winding (often just a so-called squirrel cage) in which the excitation current is induced from the armature winding on the stator. This necessitates that the asynchronous generator run slightly (1 to 2% depending on load) faster (or an induction motor slightly slower) than its synchronous speed. Important practical differences are that an asychronous generator can only function if it has a supply voltage of stable frequency to work on. It cannot generate on its own, neither can it provide reactive VA to meet system demands as a synchronous generator can. Partly for the latter reason there are relatively few asynchronous units in power generation.

- Q: I purchased a repair manual and it's not even showing anything called a resister card for a blower motor. I went to Murray's Auto Parts to have them check the relay switch,but they couldn'tt check it there. They told me to check the resister card before purchasing blower motor. The blower only runs on high speed.

- Check under dash right side by blower motor 4/5 wire plug could be facing down or you may have to take out glove box. there also may be a red lock on release for the plug

- Q: And what fuses would I need?

- You would likely use as a minimum 277/ 480 Volts, the current draw per phase would be120 amps. I'd guess the fuses would be 200 amp.

- Q: I have 2 dc motors running off a 12 volt battery charger. It works but the motors run very slow. What can I do to make them run faster. Can I use a power inverter to convert 110v, ac into 24v, dc?

- first check is the current supply on by touching the main wire

- Q: Lets say you want to use a motor from a refrigerator and stick it on a lawnmower....Can you use that dimmer to control the speed ???

- No. Refrigerator motors are a sorts that cannot be speed controlled at all. Never mind refrigerator motors are sealed in the compressor. You can use a typical lighting dimmer to control only universal AC/DC type motors, and at that not very powerful ones due to the power limit of the dimmer.

- Q: please help i am doing an assignment on electrictric motors and have no clue what this answer is.. the question isExplain where the force comes from that makes the elecrtic motor work!!!! somebody?

- Power plants.

- Q: can you connect a 1/4 hp ac motor directly to the output of ac from a windmill or turbine?

- I imagine it can be connected, but the output of the ac motor will be determined by the output of the turbine at the time. If the turbine is under-supplying power, the motor will under-perform; if the turbine is oversupplying you risk the ac motor burning out. Referring to the specifications of the turbine will help determine if its a good idea to connect it directly. I believe most windmills are designed to limit rotational speeds for safety and durability reasons - so such turbines do tend to have an upper limit of sorts (and i think this can be manually changed at that - angle to the wind etc).

Send your message to us

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords