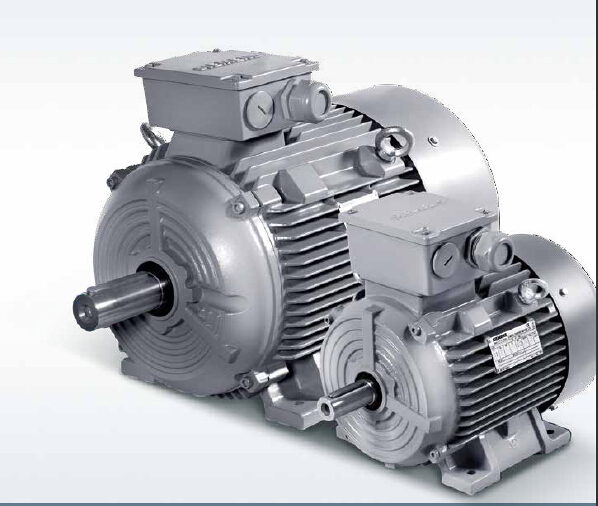

Siemens ILE0001 Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: ac motor runs then stops loud hum?

- humming usually indicates a locked rotor ,If this is so figure on a new motor.

- Q: Is 3 phase AC induction motor specified in terms of Voltage, Current Power. I have heard that a motor can be operated over a range of volt, current power. then what do the rated values indicate. Also if a motor is specified as 48 V AC, 300A then can it be operated with a battery that could supply 48V DC... neglect all the losses the need for an alternator. Thanks in advance...

- The rated voltage is nominal voltage for which the motor is designed. The voltage can vary by plus or minus ten percent or so and the motor will still deliver the rated power without overheating so much that its useful life will be significantly shortened. The rated power is the power that the motor can deliver to the load 24 hours per day, seven days a week at rated voltage and rated ambient temperature for its expected lifetime. If the load is a little higher the motor's life will probably not be effected too much particularly if the temperature is not always at the maximum. If the load is less than the rated power, the motor will probably last longer than expected. The power delivered will be only what it takes to drive the load, so it can be much less than the rated power, but the motor will be less efficient if the load is a lot less than the rated power. The rated current is the current that the motor draws when it is operating at the rated voltage and delivering the rated power. If the voltage and/or load are above or below the rated values, the current will be above or below the rated value. Over a small range of voltage variation, the current changes in the opposite direction as the voltage change so that voltage multiplied by current will be about constant. Any battery of any voltage and sufficient power delivery capability could supply power provided that the DC power is converted to an AC voltage and frequency that are appropriate for the motor.

- Q: Is it possible to run an AC motor off DC current and still have it function correctly?

- No - an AC motor will not function properly on a DC Current.

- Q: Is suppression capacitor (Volt AC) can be used as motor starting capacitor?

- I wouldn't try it. Capacitors have a maximum ripple current rating. The EMI cap doesn't have as high a rating as an oil filled motor start capacitor.

- Q: so the VFd changes the frequency of the current being used but does it pull more current when it changes the frequency? for this i am not sure if it is used to step up rpm or only step down..thanks

- Both posters are correct, frequency determines speed and current determines torque. Many VFD's can go up to 2x the normal speed, some go more. Most AC motors can do 1.5x the design rotational speed, many can do 2x, only a few can go faster than this. Motors have thermal issues limiting them to the rated HP. Because power = speed * torque, if you overspeed them, you have to have less torque. So, if it's going 2x faster, you can only get 1/2 the rated torque. The VFD has this limitation programmed in it, but on most you can also program lesser current limits. Thus, you can only overspeed the motor if the load is using less than the rated HP at the design speed. By the way, since motors are designed to provide a certain torque, at lower speeds, they are limited to that torque (except for temporary overloads like starting), so they will produce less than their rated HP.

- Q: I have an auger that is triggered every 5 seconds for 4 seconds. It spins at 1 rpm. brushless 120 VAC at .5 amp. It can handle about 100 inch pounds of torque. I don't have the ability to change the programming on the motherboard. That would be too easy. lolI want to decrease the rpm in half when I want to without burning up the coils of the motor in the mean time. Could I put a dimmer switch in series with the motor until it puts out 60VAC? I just figured it might get stuck trying to push the load and burn up. It is an expensive little motor to experiment on.Any ideas is appreciated

- Could I put a dimmer switch in series with the motor until it puts out 60VAC? it depends on the exact type of motor. universal or ac/dc motors can be speed controlled, but synchronous motors spin at a rate determined by the supply FREQUENCY so changing the voltage would do no good. Could I put a dimmer switch in series with the motor? no, dimmer switches produce spikes which would do your motor lots of no good, and produce catastrophic interference. And since its an inductive load you would also blow the dimmer.

- Q: How is the speed controlled on an electrical DC (or AC) motor? I'm sure I've heard that a motor will almost instantly reach full speed and this would be a problem in electric cars or even remote control ones, so I was wondering what components have to be used to solve this problem to allow the speed to gradually increase or to be adjusted in the case of an electric vehicle?

- En electric motor in an electric car is controlled by a controller. Simple enough... The controller limits power to the motor by sending signals to turn the motor on and off at varying intervals to give the function of speed. A typical EV controller will turn the motor on and off in segments of thousandths of a single second.

- Q: what happen if direct current is supplied to ac motor?also what happen if alternating current is supplied to dc motor?In which case motor makes to and fro motion(vibratory)?

- I expect heat and smoke in both cases.

- Q: I need to know what ac motors these are?

- They look like standard industrial AC motors with a reduction drive (to slow the rpm down). You might call inmotion simulation and ask them what brand they use: 928.759.0631

Send your message to us

Siemens ILE0001 Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords