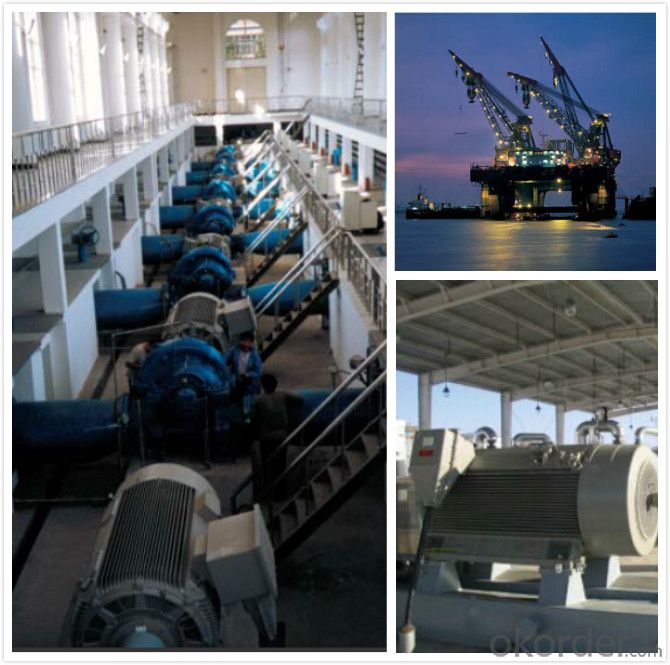

Siemens 1LA8 High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q: can avr improve power from dc to ac inverter?

- If, I understand your question properly? The most that the AVR chip will do for you? Is smooth out the wave signal of the AC power. As, AC over your home power lines comes in as a sine wave. Most common inverters are not capable of producing true sine wave. Most, at best produce a modified sine. Which means an inverter is just fine for small appliances. Like a coffee pot, small refrigerator, etc. But, create static and white noise for laptop, TV's radios, etc. These require a pure sine wave AC signal. So, yes, it will improve the purity of the power. But, nothing to boost/amplify power.

- Q: AC motors are known as the workhorse of industry.

- First but most important reason is - the AC motors are maintenance free because there is only one winding called armature. another reason is that in AC motor rotating steady parts are not touching each other so there is not any wear tear.

- Q: i know the basics of a motor but i dont know about a ac motor

- The ac motor requires 2 or more ac lines that are at some fixed phase difference between them. When wired to electromagnets arranged in a circle (called the stator), this creates a rotating magnetic field. The rotor, the rotating part of the motor, is basically a magnet that will follow the rotating field. You can even get an ac motor to work with only one ac line by using a capacitor to create another phase.

- Q: Is there any standard deviation range for AC motor speed? For example, the speed of 4 motors reached 1500, turn failed?

- AC motor: a machine used to convert mechanical energy and alternating current energy. AC motor has become the most common motor because of the great development of AC power system. Compared to the AC motor and DC motor, because there is no commutator (see DC motor commutation), therefore has the advantages of simple structure, convenient manufacture, relatively strong, easy to make high speed motor, high voltage, high current, large capacity. The coverage of AC motor power greatly, from a few watts to several 101000 watts, even millions of kilowatts. In the early 1980s, the largest turbo generator reached 1 million 500 thousand kilowatts.

- Q: I am looking to use a dc motor to power a very small, high speed fan. I need it to equate as closely as possible to a 110v 1600 rpm 1/70hp ac motor. Any suggestions would be appreciated.

- in case you're speaking some blower motor no low voltage won't harm or harm it. easily it is how your blower motor has distinctive speeds. The 12 volts from the battery is dropped for the period of a resistor coil or directed directly to the motor changing the voltage to the motor. The blower motor in line with producer can run on as low as 6 volts some even decrease. As for working below water, whether it could desire to i could anticipate that it does not final long whilst rust starts off i could anticipate this could reason binding interior the bearings. convinced i understand what i'm speaking approximately i'm a state approved mechanic.

- Q: my teacher said when a heavy load motor run low voltage he was burn because router rotation and field rotation difference is directly pro to voltage its mine voltage is up. when voltage is up. according to ohm low current is high and motor winding is burn but i'm not conform please give me a long answer with example

- With an AC motor running on a reduced voltage, slip is increased. That is the difference between the speed of the rotor and the rotating magnetic field in the stator, increases. When this happens more voltage is induced in the rotor bars, so more current flows in them. By transformer action, the current in the stator windings also increases and may lead to overheating and burn out.

- Q: I just got charged $889 to install a new motor and capacitor. Plus $89 to add frion.

- Was it the indoor fan motor for the furnace/air handler or the outdoor condenser motor? It sounds like the tech felt bad about overcharging you for the fan motor and gave you a deal on the Freon. He probably didn't add much Freon. There are no $889 fan motors (not for a 1200 sq ft townhome), there are only customers willing to overpay for a $350 motor. You said it was an AC motor. DC motors are more expensive.

- Q: The blower wheel went out because, somehow a tiny metal screwdriver got into it. Also the resistor is out and my AC isn't as powerful as it should be. Could that be the cause? PS sorry about the grammar I'm on my phone.

- Sounds like all these things are unrelated to each other. Unless you damaged the evaporator (cold coil inside the car) while changing the blower you shouldn't have had any leaks. BUT if you put the wrong screw in the wrong location and forced it in then you might have punctured the evaporator. One has nothing to do with the other unless you damaged something (or that screwdriver managed to puncture the evaporator). The resistor pack is for controlling motor speed. If your blower isn't running on high, perhaps you miss wired something. But generally I'd not expect that to be the case. The other alternative is that the resistor pack (also not related to the blower failure or the leak) may need to be replaced. Maybe that screwdriver damaged THAT. In short, if the refrigerant leaked out - you have a leak. If the fan isn't running on high - you have a motor speed control issue. 'av'a g'day mate. )

- Q: Everything I read on the Internet says that AC drive systems on locomotives is so much better than DC systems in every way. Why then when you go to the EMD factory web site do they advertise their locomotives in DC versions? Why do customers want DC locomotives?

- Probably for the same reason we do not use electric cars with fuel cells. There are a ton of good old DC motors hauling out there. The simplicity of the system makes them work and easy to diagonose and fix. The biggest draw(funny huh) back to DC is the damage that is done to the switching gear turning them on and off due to the arc that is pulled on DC comared to AC. The other trick is that generators by default create AC, which is then turned into DC, which has some loss in the process.

- Q: I want to build my own windmill for electricity

- Maybe try Popular Mechanics or another such source. Don't forget that you actually want to construct this thing in a safe and suitable manner. Maybe place some calls to companies that make wind energy windmills for personal usage, such as powering a small house, etc. Say that it us for a small school project. You might be surprised, as they might want to help you out with suggestions and the like.

Send your message to us

Siemens 1LA8 High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords