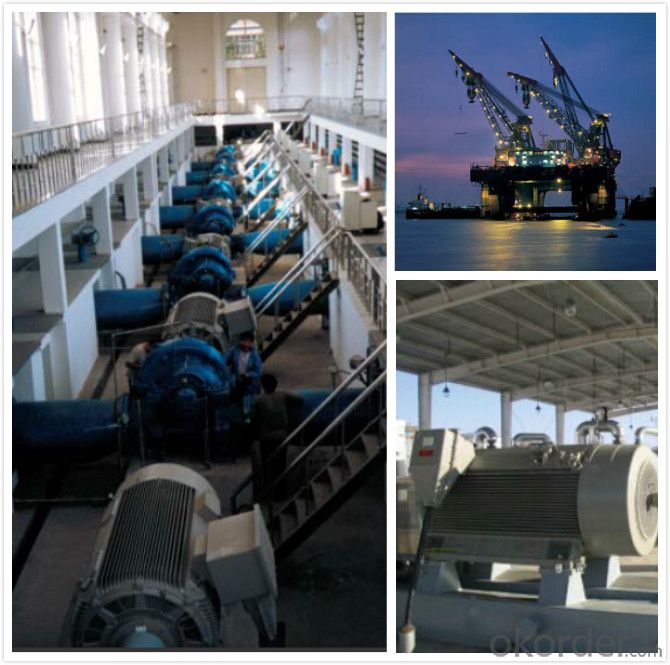

Siemens High Efficient High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q:I dont need to control the speed. What is the easiest way to convert and what would be the least expensive way. Thanks.

- What is the nameplate rating for this motor ? Voltage Running current Locked rotor current You will have to get a AC-to-DC power supply, it can be made from an autotransformer and rectifier bridges, but it won't be inexpensive, or you can buy an industrial power supply for several hundred dollars. I could not find one on Google with a quick search; that motor is too large for the 2-horsepower supplies I did find. A 2.25 hp motor is difficult to start and run on 110 V AC power because the running current will be a minimum of 15 amperes, thus requiring a sized 20 amp or larger. You will need motor overload circuit protection which is sized for the current requirements of the motor. The starting current for the motor, if the motor has a heavy load, will be more than a 20 amp breaker can handle, so you really need 30-amp service.

- Q:Heater &AC blower motor will not work in 2000grandam se? Already replaced blower and resistor.Still nothing?

- Fuse shot, or a fuseable link after the fuse, but before the blower motor...

- Q:I have an old AC/Heater that started making a squealing noise from the motor. Yesterday the motor finally died. Since I can not afford to buy another unit like this one I would like to replace the motor. Before anyone starts, I do know how to change a motor in an AC. What I don't know and what I am not finding on the internet is what motor would be a suitable replacement for the one in it now.Here are the specs....AC UNIT - Hampton Bay Model BHAC2530ES0MOTOR - Emerson Model K55HXDDM-6791Volt 208-230Amp 2.0PH 1RPM 1100/1000/90010.0 MFD / 370V CapacitorMFG # E96CFrame 48YJust need to know where I can get one like it.

- In order to buy at a supply house that sells HVAC parts, you need to be licensed. Having said that Call Grainger. Give them all the information from the motor which you have above. They should be able to cross match it. You also, need to replace the capacitor when installing the new motor. Ask Grainger what capacitor the new motor requires Here is what I found from information I have at hand .

- Q:Why AC motor speed control system will replace DC motor speed regulation system?

- PWM control is the control core of AC speed regulation system, and the final realization of any control algorithm is almost finished by various PWM control methods.

- Q:What is the difference between AC motor speed and DC motor speed?

- DC motorThe stator of a direct current motor is a fixed magnetic field, and the direct current changes through the brush of the rotor to form a magnetic field around it, thereby rotating in the stator. In industrial enterprises, due to relatively reliable DC power supply, DC motor is generally used to require reliable operation of mechanical or mechanical spare security; and because the DC motor with variable speed input voltage can also change, so often need to control local DC motor are many, such as milling machine, planer, electric vehicles, subway trains and so on.

- Q:We want to buy a paper machine from canada, the electrical power used for driving the motors (for pumps, refiners, ...) is 380 vac, 3ph, 60hz; We want to install in country with 380 vac, 3ph, 50hz.

- Monophoto has provided a very good answer, but I take exception to one point. When an AC motor is operated at a frequency that is different from the rated frequency, the voltage must be changed in proportion to the frequency change. If that is done (within some limits) the motor can produce rated torque at rated current at the new operating frequency and speed. For a 460 volt 60 Hz motor, 380 volts is the required voltage for operation at 50 Hz. However, the motors will operate at 5/6ths of the rated speed. If pulleys and gears are changed to bring the driven machinery up to the original operating speed, the torque demanded of the motors will be increased. Unless all of the motors were over-sized to begin with, they will not be able to supply sufficient torque without overheating.

- Q:In the main circuit of AC motor, fuse can be used as short circuit protection, can it play the role of overload protection at the same time, why?

- Short circuit protection: some devices can monitor abnormal conditions in the work circuit (such as short circuits). When abnormal happens, the circuit is cut off and alarm is sent to prevent further expansion of the damageA typical short circuit protection is a fuse. When the short circuit is short, the current is very high. When the fuse is blown, the circuit will be out of power.Overload protection: to prevent the main power line from overload protection caused by overheating damage and installation of overload protection equipment

- Q:What is the difference b/w stepper and ac motor?

- stepper goes forward 1 well-defined step at each pulse applied to it, while AC motor rotates continuously, which for the induction motor (the cheapest there is) depends of the frequency of the voltage it runs on. Control of a stepper requires typically 2 phases - two drivers for its two windings.

- Q:pls give me suitable region with example

- How come you deduce that AC doesnt produce a magnetic field? If there is a motion of electric charges, there is always a magnetic field. Your ceiling fan is a good example of an ac motor.

- Q:what are some things that use ac instead of dc electricity. Why do some things need ac and some need dc? Also, how are the currents changed to form ac or dc?thank you

- The okorder /

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Siemens High Efficient High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products