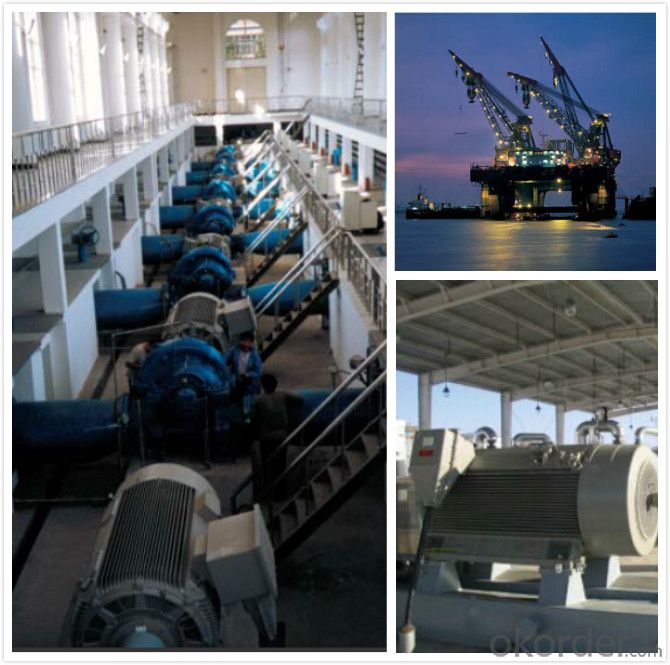

Siemens High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q: How can I control the RPM of an industrial motor of 7 horse power? I need it to have high torque and low RPM, like 100 per minute.

- If you have a way to decrease the AC input frequency thats the easiest way. Depending on the application of the motor you can have it maintain a certain RPM and simply change the power to it (by changing the amps applied) to change the HP it puts out, but that is really only certain applications

- Q: Hi, I was wondering how to connect my FASCO model K628 motor to a AC power plug. It says: brn- commonblk-208v Red, Orn,Orn 230v Its my first time doing this, and I'm really confused Thanks!

- This is a single-phase motor for use on either 208 volts or 230 volts. You need either a 208 volt or a 230 volt source. For 208 volts, connect one hot wire to the brown motor lead and the other to the black motor lead. Tape the Red, Orn, Orn lead so that the bare end can's touch anything. For 230 volts, connect one hot wire to the brown motor lead and the other to the Red, Orn, Orn motor lead. Tape the black lead so that the bare end can's touch anything.

- Q: The coil of an AC motor has a resistance of 5 ohms. The motor is plugged into an outlet where V=120V (rms) and the coil develops a back emf of 118V (rms) when rotating at normal speed. The motor is turning a wheela)Find the current (rms) when the motor first starts upb)Find the current when the motor is operating at normal speed

- At the moment the motor starts it has no back emf developed, so the current is (from Ohm's law): I = V / R = 120 volts / 5 ohms = 24 amps When the motor is operating normally it produces a back emf of 118 volts, so the total voltage across the motor is 120 volts - 118 volts = 2 volts. Using Ohm's Law again, but with the new voltage, we get: I = V / R = 2 volts / 5 ohms = 0.4 amps

- Q: If an induction motor is rated at 0.5HP and 370W at 220V single phase, is this just at start up or when under operating load. In this instance it's a submersible water pump designed for continuous duty operating on a power curve with a maximum flow rate of 400Litres/min and maximum dynamic head of 14.5 metres. Apart from general interest my main reason is that I want to get some idea of the operating costs of running this pump to supply my pond waterfall on a 24/7/365 basis.

- The rated power is the continuous rating. Start up power is understood to be higher, but of course, short lived. The National Electrical Code has information about different types of motors having start up surges of X times the continuous power. I think induction is 2 times, and household split phase motors tend to be 3 times. The half horsepower rating is impossibly amazing in combination with the power rating. It means the motor is 99.19% efficient. Almost certainly the result of multiple roundings. (Note that efficiencies over 95% only occur in very expensive motors, like 200 or more horsepower. See www.energy.wsu.edu/ftp-ep/pubs/en... )

- Q: i want an ac motor for a small wind mill as an experiment only.no matter if the motor is small.i tried the experiment on a motor from a toy but my friend said those are dc motors.i need answers on following questions:1): where from can i get an ac motor ( preferably from things of daily use / household )?2): is motor in toys AC / DC?3): can DC motors b turn into AC and how?*one who try to answer me in better way explaing (not too much) and suggesting some sites too for its pics can get his answer chosen as best at maximum rating(5 stars).thnaks

- AC Motors need single-phase or three-phase AC power only to make them work. You need a direct powered by a 110 or 220 Volts. I can suggest you can get from exhaust or extract fans, electric fans, drill machines, grinders or similar tools, blenders,mixers which have to powered by a 110/220 Volts. Toys powered by batteries always use DC Motors because they only need a low DC Voltage to run. Any devices, equipments and household or office appliances with a step down power supply inside always have a DC Motors if available. You cannot just convert a DC Motor into AC because they have different design when they built them.

- Q: are there any batteries that produce alternating current?could i put in a little alternator?

- no and no and no What voltage AC? you can get inverters that will convert 12 volts DC to 120 VAC or 240 VAC. .

- Q: why DC motors are always started through starters?

- Not always ,It depends on it c/cs and starting current precisely, as an example your CD driver contains a dc motor but it is too small no need to stater.

- Q: Hello all:I was wondering if there was a way to take an electric motor using alternating current ( AC ) and hook it up to a sort of speed controller. Some one told me speed controllers burn out AC motors; is that true?Also, is there a way to hook up a speed controller to an electric motor using direct current ( DC )?Examples:I want to put a speed controller to an windshield wiper motor.I want to put a speed controller on a ceiling fan (not a dimmer switch).Any help would be greatly appreciated. Thank you all in advance.Have a beautiful day.

- You need to get a light dimmer switch that is capable of controlling inductive lighting loads. Just connect this in series with the motor and it should give a reasonable level of control. Ensure that the dimmer switch has a large enough current rating for the motor.

- Q: How many kW or more AC Motors should be started with the starter?

- Starting of an electric motorArticle 2.3.1 when starting an electric motor, its terminal voltage shall be able to guarantee the starting torque required by the machine, and the voltage fluctuation caused in the distribution system shall not interfere with the work of other electrical equipment.Article 2.3.2 when starting an alternating current motor, the voltage on the distribution bus shall comply with the following requirements:First, in general circumstances, when the motor starts frequently, it should not be less than 90% of the rated voltage. When the motor is not started frequently, it should not be less than 85% of the rated voltage.Two, the distribution of buses on the lighting or other voltage fluctuations are more sensitive to the load, and when the motor is not frequently started, shall not be less than 80% of the rated voltage.Three, the distribution of buses on the other electrical equipment, can be guaranteed to start the motor torque conditions; for low voltage motors, but also to ensure that the contactor coil voltage is not less than the release voltage. Article 2.3.3 the choice of starting modes for cage motors and synchronous motors shall comply with the following provisions:When the following conditions are met, the motor shall be started with full pressure:1 when the motor starts, the voltage of the distribution bus meets the requirements of clause 2.3.2 of this specification:2 、 mechanical energy can bear the impact torque when the motor is started at full pressure;3. The manufacturer has no special rules for the starting mode of motors.Two, when not meet the full pressure starting conditions, the motor should buck start, or choose other appropriate starting method. Three, when the speed control requirements, the motor should start with speed regulation.

- Q: ac motor to ac generator?

- No. An ac motor has a solid stator. You would need a coiled stator in order to inject current.

Send your message to us

Siemens High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords