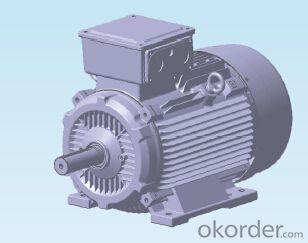

TECO High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: I replaced a capactor on my blower motor with the same value as recommended on the nameplate. 5uF, 370VAC. It opened up after about a day, then I replaced it with another one and it did the same thing. I checked the value of the cap before installing and it was correct. The motor is rated at 9A, and I am getting a current draw of less than that.

- Sounds like a short to me. Check your wiring to see if there is a nick anywhere in the insulation. Also your windings in the motor itself could be shorting. That is usually caused by the breakdown of insulation on the windings. How old id the Blower motor? Hope this helps :)

- Q: o.k I am trying to find porject Ideas, and they sayed you can transfer ac to dc power with this stuff??? and I also have a 18 gauge wire I also have in mind to make this into stuff into a small toy boat can somebody plasese help me~!

- What now? Now you own a power transformer, a dc motor and a bridge rectifier. Since none of the three things you currently own would be compatible with the others, I have absolutely no idea how you would go about making them into a small boy boat.

- Q: What is the reason that the single phase AC motor is turned on and off?

- The first type of split start type, shown in Figure 1, is assisted starting by the auxiliary starting winding, with little starting torque. The operating rate is approximately constant. Mainly used in electric fans, air conditioners, fans, motors, washing machines and other motors.Second, the starting winding does not participate in the operation, while the motor to run the winding coil continue to act, as shown in figure 2.Third, motor static centrifugal switch is connected to the power, to start after starting work in the capacitor, when the rotor speed reaches the rated value of 70% to 80% when the centrifugal switch will automatically jump, starting capacitor to complete the task, and disconnected. The running capacitor is connected to the starting winding to participate in the operation. This method is generally used in air compressors, cutting machines, woodworking machines and other heavy load and unstable place.

- Q: why DC motors are always started through starters?

- Always? not in my experience. I suppose that depends on ones definition of starter if the definition includes anything that starts a motor, then the answer is obvious, if nothing starts the motor, then the motor doesn't start. Perhaps you could add some more information, like the size of the motor and it's application.

- Q: I'm wondering about a homemade electric vehicle build using a 3 phase AC electric motor (leftover industrial application) and a Variable Frequency Drive inverter that accepts DC voltage input for the main power and a 0-10V speed input that could be attached to a quot;gasquot; pedal potentiometer. I could have these components for cheap/free if I wanted them, and I have a truck that could be used. Is this a plausible setup? Why or why not?Also, what is the recommended motor power rating for an average electric conversion? I'd like to be able to keep up with traffic at 65-70 if I need to, but I'm not interested in hot rodding around all of the time.

- Your okorder Anything is doable, even a battery powered Rolls Silver Ghost, but is it cost effective? There's the rub.

- Q: I'm trying an experiment, I want to wire a AC or DC motor to a light fixture and manually rotate the shaft which extends from the motor to generate electricity to the light bulb 60W or bigger.Can it be done, If so, Which type motor is recommend? Ac or Dc

- You will have to use the DC motor. AC motors will not work as generators unless they are wound rotor synchronous motors so you can excite the rotor from a DC power source. But turning it fast enough to generate enough power is going to be your problem. If you are turning it by hand you are going to have to have some type of gear reduction.

- Q: How to ac motor work?

- The motor uses the electricity to make temporary electromagnets. There is a ring of these magnets around the case of the motor, there are some on the rotor, the part that spins. The motor supplies power to one of the magnets around the case also to one of the magnets on the rotor. The two magnets are now attracted to each other, the magnetic power pulls the rotor towards the case magnet. Before it gets to the point that the two magnets are lined-up, it turns the case magnet off switches power to the next case magnet, that is just a bit further away. The magnet on the rotor is now attracted to the next one, the rotor is pulled around a bit further. The motor then switches the power to the magnet that's next around the case, the rotor continues to turn to try get the magnets to line-up. It's a bit more complex then that, but that should give you the general idea.

- Q: Trying to figure out how much current my attic fan draws and the label is scratched off

- 1 5 Hp Electric Motor

- Q: I'm trying to build a homemade wind generator and I'm having all kinds of trouble...I know DC motors are the easiest to work with but AC motors are the easiest to come by, at least they have been for me thus far. I have tried multiple motors some with capacitor start and a couple without. All I get out of any of them is NOTHING! LOL It's so irritating. I have a full wave diode to convert the AC to DC and I have tried all the motors both with and without the diode and that max I can get out of them is something like .02 VDC or AC it doesn't matter what I do I still get the same results. I know the meter is fine cause I have used it on little hobby motors and it read their voltage just fine. The motors do work I've plugged them in before and they run fine. Any ideas on what I'm doing wrong and thing I should try would be greatly appreciated. I'm not sure if the motor with capacitor start is a usable type for what I'm trying to do. Just came across a website a while bck that said yes Thnx

- Any motor CAN be made to work as a generator. A squirrel cage type AC motor, that has no permanent magnets in the rotor and uses the rotating magnetic field of the supplied AC to create magnetism in the rotor... will need to be started as a motor, then driven FASTER by whatever power source you are trying to employ. As soon as you start trying to drive the motor faster than the supplied AC is trying to turn it... you are generating electricity, rather than using it. There's a neat effect here.... if you AC start the generator, then engage the drive you will have automatically synchronized with the power grid. As long as you don't try to drive it TOO FAST, the squirrel cage design will keep it synchronized. So... your motor CAN be used to generate power. But you'll have to run it as a motor then start driving it with your windmill. Once its turning... you can flip the breaker off that connects it to the Grid and use the free energy. However... the AC you generate will not have a reliable frequency if you disconnect from the grid. If you leave it connected to the grid... every time the wind slows below a certain speed, the AC grid will be driving the windmill like a huge fan... and will be likely to burn the motor up, because to use it as a generator you need more than DOUBLE the fan blade area as the motor would normally drive.

- Q: What is different between AC, DC,and Servo motors? How can you control speed each motors?

- AC has multiple windings and you have to pulse the windings in a certain order to create movement. The control logic that does the pulsing can control the speed by how often it goes to the next sequence. DC is the simplest and the more voltage you apply the faster it goes. You can vary the voltage either by actually varying the input voltage or through pulse width modulation (PWM) which very rapidly turns the motor on then off, so it moves but at any variable speed (until it is off for too long, and there isnt enough torque to get it going again). Servo is generally a dc motor that is controlled all through PWM. 50% duty cycle generally means middle and the farther extremes moves it left or right. Usually they do not rotate freely.

Send your message to us

TECO High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords