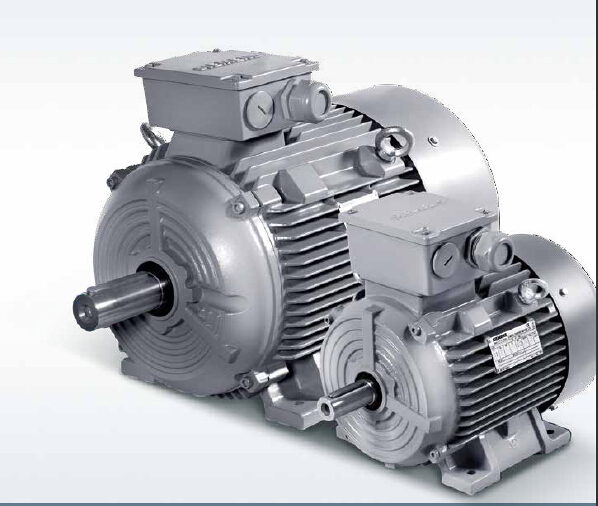

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:are there any batteries that produce alternating current?could i put in a little alternator?

- no

- Q:whats the difference between an ac motor and an ac generator,especially in its architecture, if there r any?

- AC Motor converting Electrical Energy in to Mechanical Energy. But Generator Convert Mechanical Energy in Electrical Energy.

- Q:Is it possible that i could start a fire or something? I took an old plug and connecting the motor wires to it, then i hooked the plug to the mains socket, it starts quite a big spark when it turns on, but should it be safe? even if the plug is well covered in its insulation?

- In the US you have 115 volts, the 240 v motor will run but will not have it's full power at the shaft. When a load is connected up to the rated load it will overload the motor and it will burn out.

- Q:The direction of the flow in the pump with DC/AC motor?

- what is your question? It turns the same way the motor turns.

- Q:Can't tell from owners manual which fuse it is.

- get a fuse tester.

- Q:What's the difference between DC motor carbon brush and AC motor carbon brush?

- The role of the motor is to change the current direction of the DC motor and AC motor, the DC motor is to change the rotor's conductive coil, thereby changing the rotor magnetic pole. Thereby changing the motion of the motor. The carbon brush is used for motor commutator or slip ring, as sliding contact body import and export current, its thermal conductivity, and good lubrication performance, and has certain mechanical strength and direction of the spark of instinct. Almost all motors use carbon brush, which is an important component of the motor.

- Q:What is ac servo motor?

- I'd think a servo under dash that moves doors inside A/C and heat, defrost if you're talking automobile.

- Q:equtions of rpm of 3 phase ac motor?

- The rpm of AC motor does not depend on the phase. It depends on the number of pole and frequency of the line. frequency * 60 rpm = --------------------- 2 poles = 30 freq/poles.

- Q:My A/C went out last Friday. I had the starter motor capacitor replaced, which had blown out. It ran fine for 4 days and then blew again. I just went and got the same capacitor that ran for 4 days and turned my system on and it immediately blew out. What could be causing my caps to blow? Is it the relay? Maybe a short?

- Starter Motor Capacitor

- Q:Specifically, what happens if I put AC electricity in a DC brush-less CPU fan? I read some where that DC brush-less motors are like AC motors.

- You would blow it up. Brushless motors use solid- state commutation, and applying AC to electronics is a no- no.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords