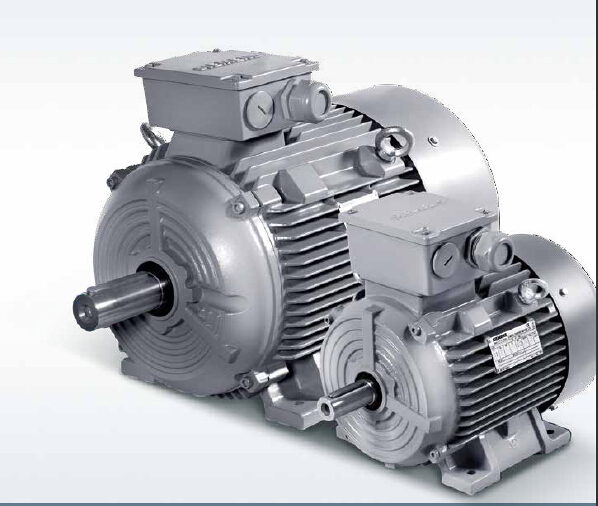

Siemens 1PQ Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: what might be the sypmtoms, if theres a problem with brusehs or/and slip rings of a DC motot and of an AC motor ?whats the solution of this problem ?thanks

- If you isolate your question only to the rings or brushes, you can narrow possible problems down to corroded/worn parts, overheated parts, or poorly installed parts. The symptoms will most likely be the motor not functioning at all, refusing to start itself but will run with a little helper push, noises from the end with the parts, or a completely locked up motor. The solution to the problem is most always replace the worn parts. In most cases ive seen tho, if the rings or brushes have worn naturally (without the help of careless operator), other parts are getting ready to go out (bearings, coils, and such). The symptoms can differ between the types of motors as well and always check the input power source and controller before you pull the motor apart.

- Q: Please elaborate the formula or technique of speeding up the motor used in sirens...?

- previous the line the decrease contains the supply of more desirable life help and for regulation enforcement to supervise crash web content. seventy 5 mph is plenty extra survivable than 80 mph, which in turn is plenty extra survivable than 80 5 mph. At a hundred mph basically approximately all injuries are fatalities, which (from a regulatory point of view) can tie up officers and close down the line for one million/2 an afternoon. At a hundred and twenty mph, see the video interior the 1st resource. autos might desire to be designed for a optimum impression velocity, the cost at which the cave in zones are exhausted and the restraints have executed all they might. interior the Seventies it become everyday the candy spot for optimum impression velocity for passenger autos become approximately 80 mph. via that velocity fatalities are uncomplicated besides so it did not rely if the automobiles have been designed for ninety mph. velocity limits replicate the jurisdiction's willingness to handle the carnage from larger speeds. 70 mph is fantastically risk-free, 80 mph is inquiring for difficulty. ninety mph is basically uncomplicated stupid.

- Q: What determines voltage usage for electric AC motors?

- The design. It will be designed for a particular voltage usage.

- Q: The engine would be for a boat so another question i have is does anyone have any idea how to calculate or figure how many kw it would take to run a dc motor like that obviously it would not be running at 715 hp the whole time because that is only needed for acceleration. Thank you!!!!!!!

- this must be a big boat. 715 HP converts to 533 kW by my calculator. Usually an electric motor can be smaller than an equivalent gasoline engine as it has a wider torque range. and now you see why electric cars are so difficult to make. If you used a 100 kW motor, 150HP, you would need hundreds of pounds of batteries to run it for an hour. 1 large battery has 1kw-hr of power. 100 of these would give you 100kW-hrs, enough to supply a 100kW motor for 1 hours. At a weight of maybe 2000 pounds.

- Q: I have a 2001 BMW 325i..the air conditioning completly went out about 2 weeks ago, nothing would work. I took it to a repair shop m,y buddy owns (so i know he didnt cheat me) and they said it may be the blow motor, so they fooled around with it and it started working after 5 minutes of messing with it it automatically came on and started working. They said the antifreeze was low so they filled that up also and I was on my way....about 3 days of the air conditioning working fine, i came out side and id had the ac on high went i turned the car off and it was still on....now even if the cars off the air still blows on high, if you try to turn the air off or turn it down its still on....what could it be??????

- bad ac switch. its not sending the right signals or maybe no signal

- Q: I have a DC power source that I'm trying to convert to AC. The DC power can be anything. The only catch is that the AC delivered needs to be only 5 VAC with a frequency of 60Hz and a current of 1 Amp. Is there any way to achieve this without a transformer? If I do have to use a transformer to make an inverter, how do I meet these other specifications?

- First of all, remember that the AC signal can be at most, in a perfect world (which ours is not), equal to the wattage of the DC input. 5 VAC (RMS), at 1 A, will require a 5 W DC input. In practice you should at least double this. The technical term is an inverter. You can buy an off-the shelf inverter and connect it to a transformer. Since you're shooting for low voltage, you can also just build one with a 555 timer and a power transistor that can handle 1 A. You'll need to filter the output (with a big inductor or an RC bridge) if harmonics will be a problem. The quickest simplest way to do this is to build yourself a dynamotor by connecting the shafts of a DC motor and an AC motor. You can very easily generate this kind of power, and it will be exceptionally clean and noise-free, unlike the output of an inverter. But you have one other option: a cheap PA amplifier (remember, you only need 5 watts) and a sine wave generator (which can be any wall transformer with a large resistor in series to prevent excessive current from flowing). Just turn the volume knob until you get the voltage you want. If the whole rig needs to be able to run on DC, you can construct the sine wave generator out of a 555 and an RC filter with a very low cutoff.

- Q: I want to attach 2 series motors to 40V AC how much current do I need if each motor is 24V DC?

- It won't work. You can't connect a DC motor to an AC supply. It will just sit there and eventually burn out.

- Q: I have an ac electric motor 7.2hp 3600 mounted to a vertical mixer and gear reducer that is shooting out sparks. Any reason as to why this is happening?

- At 7.2 Hp it must be a 3 phase motor. Are the sparks coming from the terminal box or from within the motor (if it is screen protected not TEFC). If the sparks come from within the motor, then it'd probably beyond repair ans will need a rewind or replacement. if they come from the terminal box, check for loose connections, abraded insulation loose connections etc.

- Q: How to synchronize two ordinary AC motors?

- I'm afraid it's not easy. Ordinary AC motors are asynchronous motors. Two identical motors, when the load is exactly the same, and at the same time, it is possible to synchronize, but this synchronization is prone to damage. Personal view, for reference only.

- Q: I have an old AC/Heater that started making a squealing noise from the motor. Yesterday the motor finally died. Since I can not afford to buy another unit like this one I would like to replace the motor. Before anyone starts, I do know how to change a motor in an AC. What I don't know and what I am not finding on the internet is what motor would be a suitable replacement for the one in it now.Here are the specs....AC UNIT - Hampton Bay Model BHAC2530ES0MOTOR - Emerson Model K55HXDDM-6791Volt 208-230Amp 2.0PH 1RPM 1100/1000/90010.0 MFD / 370V CapacitorMFG # E96CFrame 48YJust need to know where I can get one like it.

- You should have an appliance parts wholesaler in your or the largest nearby town. give them the information and they should be able to order one, option 2 is go to a motor place, (they are becoming rarer these days, and they can usually rebuild or order a replacement motor. But be fair warned that they are not cheap. Many companies dont work on window units because you can replace them cheaper than repairing them. My grandfathers went out so I was going to put new motor in it. I ordered one from an appliance parts supplier threw my companies account at thir wholesale price and it was $167 cost for the part 5 years ago. I could have just bought him a complete new one and saved time and Money. anyways get a price before you order it.

Send your message to us

Siemens 1PQ Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords