Tabe Formwork for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

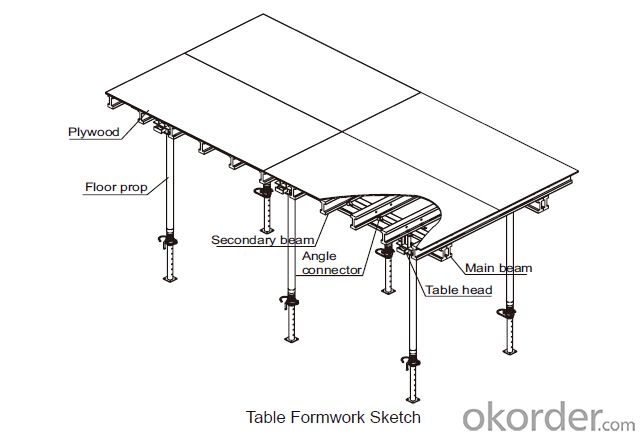

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q:Can steel formwork be used for projects with aggressive concrete mixes?

- Yes, steel formwork can be used for projects with aggressive concrete mixes. Steel formwork offers high strength, durability, and resistance to chemical reactions, making it suitable for projects involving aggressive concrete mixes. It can withstand the harsh chemical environment created by aggressive concrete mixes and provide a reliable and long-lasting formwork solution.

- Q:What are the different types of connections used in steel formwork?

- There are several different types of connections commonly used in steel formwork, each with its own advantages and applications. Some of the most common types include: 1. Bolted connections: These connections involve using bolts and nuts to secure the formwork components together. Bolted connections are versatile, relatively easy to assemble and disassemble, and provide a high level of strength and stability. They are often used for larger formwork structures or where high loads are expected. 2. Welded connections: Welding is another popular method of connecting steel formwork components. Welded connections offer excellent strength and durability, as the pieces are fused together. However, welding requires skilled labor and specialized equipment, which can increase costs and time. 3. Clamped connections: Clamped connections involve using clamps or couplers to hold the formwork components together. Clamped connections are quick to assemble and disassemble, making them ideal for temporary structures or situations where frequent changes are required. They also offer flexibility in terms of adjusting the formwork components' position. 4. Pin connections: Pin connections involve using pins or dowels to join the formwork components together. These connections are relatively simple and can be quickly assembled or disassembled. However, pin connections may not offer the same level of strength as bolted or welded connections. 5. Adhesive connections: Adhesive connections involve using an adhesive or epoxy to bond the formwork components together. This type of connection is commonly used for smaller or lightweight formwork structures. Adhesive connections provide a strong bond and are often used in situations where welding or bolting is not feasible. Each type of connection has its own advantages and disadvantages, and the choice depends on factors such as the formwork structure's size, load requirements, desired level of strength, and project timeline. Consulting with a structural engineer or formwork specialist can help determine the most suitable connection type for a specific project.

- Q:Can steel formwork be used in heritage or conservation projects?

- Yes, it is possible to utilize steel formwork in heritage or conservation projects. Steel formwork possesses numerous advantages that render it appropriate for such endeavors. Firstly, steel formwork exhibits exceptional durability and longevity, making it indispensable when working on historical structures that necessitate preservation for future generations. It can endure the challenges of construction and can be reused multiple times, thus offering a cost-effective solution. Furthermore, steel formwork provides outstanding strength and stability, guaranteeing accurate and precise concrete placement. This is particularly critical in heritage projects where maintaining the original design and structural integrity is paramount. The adaptability of steel formwork also enables the replication of intricate detailing and complex shapes, thereby making it suitable for recreating historic architectural features. Moreover, steel formwork is highly resistant to warping, shrinking, or expanding due to temperature fluctuations and moisture, which are often encountered in conservation projects. This resistance ensures the formwork's stability throughout the construction process, reduces the risk of harm to the heritage structure, and aids in preserving the overall structural integrity. Nevertheless, it is crucial to take into account the specific requirements and limitations of each heritage or conservation project. Certain projects may have stringent guidelines mandating the use of traditional materials, rendering steel formwork unsuitable. It is imperative to consult with heritage experts and conservation specialists to ensure that the use of steel formwork aligns with the project's objectives and adheres to all necessary preservation standards.

- Q:How does steel formwork affect the quality of concrete?

- Steel formwork can greatly affect the quality of concrete by providing a stable and precise mold for the concrete to be poured into. The use of steel formwork helps ensure uniformity in shape, size, and surface finish of the concrete, resulting in a higher quality and more consistent end product. The strength and durability of steel formwork also enable it to withstand the pressure exerted by the wet concrete, preventing any deformation or leakage that could compromise the integrity of the concrete structure.

- Q:What are the different sizes and dimensions of steel formwork?

- Steel formwork is available in various sizes and dimensions to cater to different construction requirements and project needs. The most common sizes of steel formwork panels are typically 2 meters (6.5 feet) in height and 1 meter (3.2 feet) in width. However, these dimensions can vary depending on the manufacturer and the specific project requirements. In terms of thickness, steel formwork panels are usually between 12 to 14 millimeters (0.5 to 0.6 inches) thick. This thickness ensures the panels are sturdy enough to withstand the pressure exerted by the concrete during the pouring and curing process. Additionally, steel formwork panels are available in various lengths to accommodate different wall heights and dimensions. These lengths can range from 1 meter (3.2 feet) to 4 meters (13.1 feet) or even longer, depending on the project requirements. Apart from panels, steel formwork systems also include other components such as beams, props, adjustable struts, and connectors. These components come in different sizes and dimensions to support the formwork structure and ensure stability and safety during the construction process. It is important to note that the dimensions and sizes of steel formwork can vary depending on the manufacturer, project specifications, and regional construction practices. Therefore, it is crucial to consult with the manufacturer or a structural engineer to determine the appropriate sizes and dimensions of steel formwork required for a specific construction project.

- Q:Can steel formwork be used for precast concrete beams with complex geometries?

- Yes, steel formwork can be used for precast concrete beams with complex geometries. Steel formwork offers numerous advantages for creating complex shapes and designs in precast concrete beams. Steel is a strong and durable material that can withstand the pressures and forces exerted during the concrete pouring and curing process. It can be easily fabricated to create the desired shape and size of the beam, making it suitable for complex geometries. Steel formwork also provides excellent dimensional accuracy, ensuring that the precast concrete beams maintain their intended shape and dimensions. This is particularly important for beams with complex geometries, as any slight variation in shape could affect their structural integrity. Additionally, steel formwork offers a smooth and high-quality finish to the concrete surface. This is essential for beams with complex geometries, as a smooth surface ensures proper load distribution and reduces the risk of cracking or other structural issues. Furthermore, steel formwork can be reused multiple times, making it a cost-effective option for creating precast concrete beams with complex geometries. The versatility and durability of steel formwork make it a preferred choice for many construction projects, including those involving complex precast concrete beams. In conclusion, steel formwork is a suitable and practical choice for creating precast concrete beams with complex geometries. Its strength, durability, dimensional accuracy, and smooth finish make it an ideal solution for achieving the desired shape and design in these beams.

- Q:What are the common challenges faced during steel formwork installation?

- Some common challenges faced during steel formwork installation include ensuring proper alignment and leveling of the formwork, handling heavy and bulky steel components, securing the formwork against displacement during concrete pouring, and maintaining structural stability and integrity throughout the installation process. Additionally, coordinating with other construction activities, such as rebar placement and concrete pouring, can also be a challenge to ensure smooth and timely progress of the formwork installation.

- Q:What are the common safety guidelines when working with steel formwork?

- When working with steel formwork, there are several common safety guidelines that should be followed to ensure the well-being of workers and prevent accidents. These guidelines include: 1. Personal Protective Equipment (PPE): All workers should wear appropriate PPE, including safety helmets, safety glasses, gloves, and steel-toed boots. This will protect them from falling objects, cuts, and other potential hazards. 2. Training and Competency: Workers should receive proper training on how to use and handle steel formwork. They should be knowledgeable about the specific tasks they are assigned and have the necessary skills to perform them safely. 3. Inspections: Regular inspections of the steel formwork should be conducted before and during use to ensure that it is in good condition and free from defects. Any damaged or faulty parts should be repaired or replaced immediately. 4. Proper Handling: Steel formwork can be heavy and cumbersome, so it is essential to use proper lifting techniques and mechanical aids when moving or positioning it. Avoiding excessive strain and overexertion can help prevent musculoskeletal injuries. 5. Secure Installation: The formwork should be securely installed and braced to prevent collapse or displacement during concrete pouring. It should be properly aligned and supported to ensure stability throughout the construction process. 6. Fall Protection: Adequate fall protection measures, such as guardrails or safety harnesses, should be in place when working at heights. Additionally, workers should be cautious of slippery surfaces and take necessary precautions to prevent slips, trips, and falls. 7. Hazard Communication: Clear signage and warnings should be posted to alert workers to potential hazards and provide instructions on safety procedures. Communication among workers and proper coordination is also crucial to prevent accidents. 8. Regular Maintenance: Routine maintenance and cleaning of the steel formwork should be performed to remove debris, rust, or other materials that could compromise its integrity. This will help ensure its safety and longevity. By following these common safety guidelines when working with steel formwork, the risk of accidents and injuries can be significantly reduced, creating a safer work environment for all involved.

- Q:How does steel formwork handle concrete pumping and placing?

- Steel formwork is a highly durable and versatile construction material that is well-suited for handling concrete pumping and placing. Due to its strength and rigidity, steel formwork can withstand the pressure exerted by the concrete during the pumping process without any deformations or failures. It provides a stable and secure framework, ensuring that the concrete is accurately placed and consolidated. Steel formwork also offers excellent resistance to the abrasiveness and corrosiveness of concrete. This is especially important during the pumping and placing stages, as the concrete is often mixed with various additives and can have a high alkaline content, which can be destructive to other types of formwork materials. However, steel formwork is unaffected by these chemical reactions, making it a reliable choice for handling concrete pumping and placing. Moreover, steel formwork is easily adjustable and adaptable, allowing for the creation of complex shapes and designs. It can be easily assembled and disassembled, enabling efficient and quick reconfiguration of the formwork system to accommodate different concrete pumping and placing requirements. This flexibility makes steel formwork a preferred choice for projects that involve intricate or customized concrete structures. Additionally, steel formwork provides a smooth and consistent surface finish to the concrete, ensuring that the final structure meets the desired aesthetic and functional requirements. The rigid nature of steel formwork helps prevent any deformations or irregularities in the concrete surface, resulting in a high-quality and visually appealing end product. In summary, steel formwork is an ideal choice for handling concrete pumping and placing due to its strength, durability, resistance to chemical reactions, adaptability, and ability to provide a smooth finish. It offers a reliable and efficient solution for construction projects that require accurate and precise concrete placement.

- Q:Is steel formwork suitable for projects with high wind loads?

- Yes, steel formwork is suitable for projects with high wind loads. Steel formwork is known for its strength, durability, and stability, making it an ideal choice for construction projects that are subject to high wind loads. Steel formwork provides excellent resistance against wind forces and can withstand strong winds without deformation or damage. Additionally, steel formwork offers a high level of dimensional accuracy, ensuring that the structure can withstand the forces exerted by the wind without compromising its stability. Therefore, steel formwork is a reliable and suitable option for projects with high wind loads.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tabe Formwork for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords