Multistage Centrifugal Pump for Boiler Feed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Multistage Centrifugal Pump for Boiler Feed

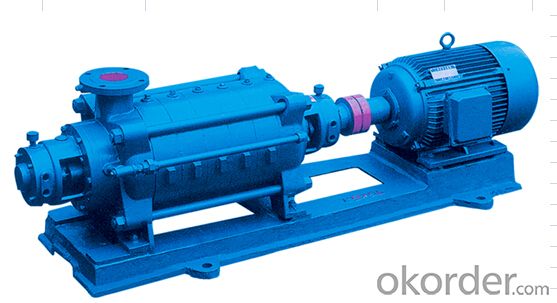

1.Structure of Multistage Centrifugal Pump for Boiler Feed Description

The high presuure boiler feed multistage water pump is a horizontal multistage centrifugal pump and suitable for transporting pure water,both ends of it are supported,the casing portion is a senctional form,it is connected and actuated by motor via a resilient clutch.From the driven direction,the pump rotated direction is clockwise.

2.Main Features of Multistage Centrifugal Pump for Boiler Feed

• High Effiency

•Low noise

•Long life, OEM and ODM are welcomed.

3.Multistage Centrifugal Pump for Boiler Feed Images

4.Multistage Centrifugal Pump for Boiler Feed Specification

Material |

Cast iron and as customer's request |

Temperature |

Less than 150°C |

Flow rate | 3.75-300m3/h |

Head | 75-1000m |

Medium temperature | 0 ~170°C |

Operation pressure | ≤40 bars |

5.FAQ

①What is the applications?

Power Station,Industry Water Supply

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

- Q: I have had this water pump changed 2 times in 5 years is this normal for this car? It has a v6 motor.

- 1. Remove any radiator shroud, or any cowl obstructing the fan, radiator, and water pump. 2. using a pair of large pliers, take off the clamp on the lower radiator hose at the water pump and drain the coolant into a container. Make sure the motor is COLD, room temp, when you do this. 3. Remove the other hose. 4. Remove the cooling fan using an air hammer or a large adjustable wrench. This part is tricky, unless your fan is bolted on with 10 mm bolts, then you lucked out. 5. For step 4, leave the belt on, it will make it easier to remove the fan. 6. If you have a V-8 LT-1, then you have 4 13 mm bolts. Be careful not to damage your distributor which sits under the pump (nice design GM) 7. Using a razor blade, remove any gasket on the inlet and outlet on the block. 8. Apply a thin layer of gasket sealer on the gaskets for the new pump. 9. Install the pump, and its bolts. Use locktite if you have some on the bolts, medium strength. Tighten the bolts to about 90 in/lbs 10. install the pully, and fan. (again, tricky) 11. Install the belt. 12. put lower radiator hose back on (leave off upper) 13. pour 1/2 a bottle of Dex-cool coolant in the radiator 14. fill bottle up with 1/2 water, 1/2 coolant, and pour it into the reservoir. 15. If necessary, get new bottle of coolant, and pour it into the UPPER RADIATOR HOSE, this will help bleed air out of the system. 16. keep filling upper hose, and radiator until it stops bubbling down and basically overflows. 17. install upper hose. 18. make sure the radiator is full and system has no air pockets. Check to see if the upper radiator hose inlet has a bleeder valve. If it does, use a pair of pliers and open it, and watch coolant in radiator drop, then fillit up again. The V-6 has one, not sure about V-8. 19. put radiator cap on, and resevoir cap. 20. run motor, check for any leaks. 21. drive, if vehicle is overheating and there are no leaks, there is still air in the system. Wait till it cools down and bleed air again.

- Q: belt removal mercury cruiser water pump?

- The pump bracket pivots that allows the belt to be removed. I've seen a few where the alternator belt is over the top of the water pump belt, so you have to remove it first. Actually a pretty easy job.

- Q: cars leaking coolant from the right side just dont kno if its the water pump

- Water pump will be at the front center of the engine usually about 2 behind the fan belt Please be very careful never to allow the vehicle to run low on coolant or serious and expensive engine damage will occur. If in doubt don't drive it until its fixed Take a flashlight and take a good look over the whole engine compartment giving close attention to all the hoses connecting the engine to the radiator its best to find the exact location of the leak and get it fixed.Coolant leaks usually leave a discolored stain so this may help in finding it. Also take a look at the carpet on both front floorpans of the vehicle its possible that the cars heater may have failed and this will leak coolant all over either 1 or both floor pans which can then leak out on to the ground below via a drain hole.

- Q: new switch and new tank

- Sounds like the thermal is cycling. Check it and clean out debris. (overheating)

- Q: I just bought a house a little more then a month ago and just received my first electric bill and it's OUTRAGEOUS!! I have a feeling my electric pump is doing most of my water heating which I found out it is (currently it's on 24 hours a day .. I didn't know). Now, I called a solar company in my area that deals with Hartell pumps, they said if the Hartell pump is working, it should be vibrating .. mines is not .. are they correct? They also said it only works when the sun is out, so by evening, I have to switch on my electric water heater. I'm just checking to see if I'm receiving the correct information before I time my electric water heater .. since every other local solar company I called are unfamiliar with Hartell pumps.

- OK, well your question is a bit confusing and I am not sure if it is because you don't understand how your system works. Your hartell pump pumps water. It does not produce heat. Your water heater heats water. It is a backup to your solar panel system. If on the other hand you have a heat pump as a back up source of heat this could be an entirely different matter and you are best at providing a model number which should be stamped on the part. We need to start again. Is your system for solar hot water or for general heating? Is it a system in a cold climate where freezing is an issue. Is it a pump down system or a system that circulates antifreeze in the solar loop. The reason all this is significant is that if you are paying a lot in electricity then something is not working. The first question has to be is it a design problem, a mechanical problem or an operational problem. You may need more hot water storage or more solar panels, you may need to replace parts, or you may simply need to turn the right valves (This would be the case where you have a grounding loop to keep the solar panels from overheating in the summer.)

- Q: I just had my water pump/timing belt replaced and oil change. When the pump failed, white smoke was coming out, which I figured out to be coolant from the smell. Now there is smoke coming out from under the engine, which I believe to smell like oil. Also, the temperature gauge goes up to the halfway point when I am at a stoplight or idling. The highest I have ever seen it is at 1/3.I had my car serviced by the dealership and I asked them. The man said its burning oil residue from the oil change and that it will burn away in a few days. Is this true? I have had my car worked on and oil changed for the past year at this dealership and have never had any smoke or other problems. What else could be going on? Worse case scenarios. Thanks everyone.

- Almost every time i have seen this in my 35 years of exp.its turned out to be a cracked block or head.

- Q: i have little leak from water pump need to replace it in my mazda 6 2006 v6 3.0l. i have little over 120.000 miles on it. Any body know how much it may cost me?

- I don't know why, but the water pump costs between $125 and $160. That seems a little high. It probably retails for $186. Under normal conditions, you just get things out of the way, unbolt the old pump, clean it up and put the new one in. The problem is the other stuff that gets in the way. I'm just estimating the job will take 5-8 hours. Just multiply times the labor rate in your area. Don't forget the anti-freeze when you're done.

- Q: I think my water pump has crapped out on my 1997 Jeep Cherokee. I have been leaking coolant for a few days now and there is a puddle under my Jeep after I turn it off and my reserve tank keeps emptying out on me. I replaced the lower radiator hose and still the same problem. It is not over heating so I am wondering if it IS a water pump problem? If it is, could I do the work myself?

- First thing is to stop driving it or you will have a bigger problem (ask me how I know this). Next go to your local parts store and get a repair manual, a rebuilt/new water pump and some gasket sealer. Then get to work. Good luck!

- Q: Today I see the saying that if your pipe diameter has been selected, then the pipe diameter on the pipe diameter should be smaller. I don't know why

- In order to reduce the water outlet resistance of pump outlet.The statement should be: if your pump has been selected, then the outer outlet pipe caliber than the water pump outlet diameter one.

- Q: What is the difference between a sewage pump and a clean water pump? Why can't sewage be pumped with clean water?

- The main difference between water pump and sewage pump is that:Impeller and runner design, as well as other parts of the configuration are very different.1., in order to prevent clogging of sewage pump, the main design of large flow channel, so naturally lead to relatively low efficiency, so the head is generally not high. Clear water pump flow smaller, smaller clearance, the head is relatively high.2. in order to prevent the wound, water pump impeller design is more simple but not ring pump, equipped with tips, cloth and other debris can be crushed after the pump, and the impeller water pump is relatively complex, but the efficiency will be significantly higher than the former.Why can't the sewage water pump and impeller: because features of key design, resulting in water pump for sewage situation is likely to occur, blocking, winding, wear and corrosion occurs, resulting in damage to pump or scrapped, so water pump can not be used for sewage.Sewage pump is a pump and motor conjoined, and at the same time submerged into the work of pump products, and general horizontal pump or vertical sewage pump compared to the sewage pump compact structure, small footprint.The water pump is for the transport of water and physical and chemical properties similar to water and other liquids used, suitable for the industry and the city water supply and drainage, water pressure high-rise buildings, garden sprinkler, fire booster, long-distance transportation, HVAC refrigeration cycle, irrigation, bathroom, cold and hot water circulation pressurization and equipment.

Send your message to us

Multistage Centrifugal Pump for Boiler Feed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords