Boiler Feed Centrifugal Multistage Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

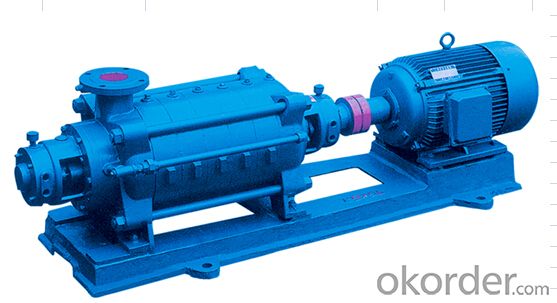

Boiler Feed Centrifugal Multistage Water Pump

1.Structure of Boiler Feed Centrifugal Multistage Water Pump Description

Boiler Feed Centrifugal Multistage Water Pumpis used for transporting pure water (particles density shall be max.1%by volumeand granular size shall be max 0.1mm in dimeter) of the liquids with physical and chemical properties similar to pure water. Type MD pump is applied with wear resist material, especially suitable for mineral drainage. The particles density shall be max. 1.5% (Max. of the granular diameter is 0.5 mm).The liquid temperature ofD, MD pumps shall be lower than 80°C.

2.Main Features of the Boiler Feed Centrifugal Multistage Water Pump

• Compact structure, good appearance, low construction

•Operation stably, same inlet and outlet

•Convenient installation and maintenance

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

3. Boiler Feed Centrifugal Multistage Water Pump images

4. Boiler Feed Centrifugal Multistage Water Pump Specification

Item | Multistage Pump |

Multistage Pump | Horizontal Multistage Pump For Pure Water |

Model | CMD |

Material | Cast iron,Stainless steel |

Mode | Horizontal |

Color | Blue |

Temperature | <=80°c< span=""> |

Seal | packing seal |

Theory | Centrifugal Pump |

Structure | Multistage Pump |

Usage | Water |

Power | Electric |

Standard or Nonstandard | Standard |

Fuel | Diesel |

Pressure | High Pressure |

Application | Hot and cold pure water |

Outlet Diameter | 40-500mm |

Capacity | 6-1250 m3/h |

Head | 75-1800m |

Rotation Speed | 1450-2950r/min |

Power | 5.5-2400kW |

Certificate | ISO9001 |

Feature | High efficiency,Easy maintenance |

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: How to adjust the flow of piston pump?

- Changing the size of the current in the solenoid valve can change the angle of the tilting element, and then change the stroke length of the plunger in the pump cylinder, that is to say, to change the flow of the pump. An inclined angle is called a quantitative pump, and the angle of inclination can be changed, which is called a variable pump.

- Q: What is the dry running protector of screw pump? What's the principle and function? Thank you

- Principles are generally temperature sensing, such as: when the screw pump by air, the stator and rotor will be heated due to friction,

- Q: What should I pay attention to when buying a pump?

- Two, the first choice of large and medium-sized professional manufacturers, and through the quality identification of relevant departments, the market credibility of the better models, but also to the professional quality inspection institutions consultation.Three, check the motor grounding device for electric pump, water pump and motor axis, the motor should be in a proper position is provided with a grounding screw, and the grounding screw are arranged near the ground; grounding device of small submersible pump should be reliable and grounding wire, grounding wire cables should have the obvious grounding mark the flag should be in use; the motor is not easy to be worn during the period. This is one of the important safety indexes of electric pumps.

- Q: What is the principle of a turbopump?

- Turbine [turbine] is a machine that converts the energy contained in a fluid medium into mechanical work, also called a turbine. Turbine is the transliteration of English turbine, derived from the Latin word "turbo", meaning "rotating object".

- Q: What is the relationship between the minimum suction vacuum of a pump and the required cavitation?

- When the pump is working, the liquid at the inlet of the impeller, due to a certain vacuum pressure will produce steam, the vaporization of the bubble in liquid particles under the impact of movement, the impeller and other metal surface erosion, thereby damaging the impeller and other metal

- Q: Is the sewage pump the same as the mud pump?

- Two of the main performance parameters of mud displacement and pressure, displacement from a number of liters per minute, with the diameter and the drilling fluid requirements from the hole on the back end of the speed, the larger aperture, the greater the displacement. The upstream return speed of the washing fluid is required to remove the cuttings and rock powder from the drill in a timely manner from the bottom of the hole and reliably carry it to the surface. Through drilling and extraction, mud can be obtained at the bottom.Sewage pump is mainly used for industrial wastewater treatment, sewage treatment, environmental protection has played a big role. Among them, the sewage pump is also a sewage pump with cutting wheel, such sewage pump can be chopped dirt, and then extract the sewage clean.

- Q: The working principle of magnetic pump

- Working principle of magnetic pumpN of the magnet (n is even) arranged according to the laws in the magnetic clutch assembly inside and outside the magnetic rotor, the magnet part consisting of magnetic coupling system. When the inside and outside the two poles in different relative displacements, two poles between the angle phi = 0, the lowest energy magnetic system; when rotates to the relative displacement is two poles, pole angle between phi = 2 pi /n, the magnetic system of magnetic energy. Remove the external force, due to the magnetic system of magnetic poles repel each other, magnetic magnet will return to the lowest energy state. So magnets in motion, driven by the magnetic rotor.

- Q: Why does the centrifugal pump start with a closed valve and the axial pump starts with an opening valve?

- Because the characteristic curves of the two are different.The power of centrifugal pump decreases with the decrease of flow rate. When the flow rate is zero, the power is minimum, so the centrifugal pump is started with a closed valve.

- Q: Why is the submersible pump tripped on an electrical switch?There is no electrical leakage protection, directly connected to the circuit breaker, and when the switch on, the circuit breaker jumpedI checked the line is good, the pump did not break down, is not the water pump?

- Calculate or refer to the water pump nameplate that the normal operating current, according to this data exchange switch.2) with 500V shaking table, measuring the cable, motor insulation is in line with the requirements

- Q: How to maintain and repair the booster pump of pipeline pump?

- I. installationAssembly and disassembly1. scrub all the spare parts to be cleaned.2. mechanical seals are installed on the main shaft of the motor, and a small amount of clean turbine oil or 20 oil is added to the surface of the mechanical seal.

Send your message to us

Boiler Feed Centrifugal Multistage Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords