Injection Hot Runner PET Preform Mold for Mineral Water Bottle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

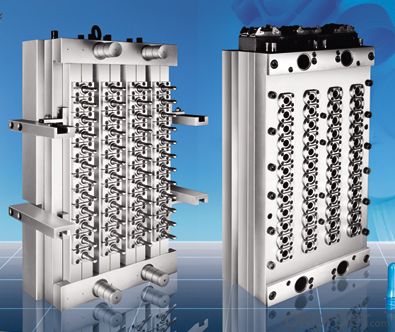

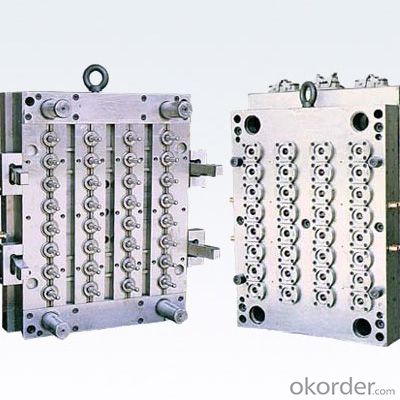

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

. Features of the perform mold. No cutting of valve gate is employed to reduce the labor cost.

. Advanced hot runner system assures lower level of AA value.

. Reasonable- designed cold water channels increase cooling effect and shorten the cycle time.

. The main components of perform molds are made of 2316 material (Sweden ASSAB).

. The mold base is made of imported P20. plate method avoids corrosion efficaciously and assures long life service of the perform molds.

. German Vacuum stove is imported for heat treatment of the components, which assures the hardness of components HRC45-HRC48.

. Many machine tools are imported from America and Japan, such as Machine center, CNC lathers, EDM and so on. All of these increases processing precision, good interchangeability and low eccentricity ≤0.10mm (perform length≤100).

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

PET preform injection mould with normal long tail availabe.

short tail mould available.

valve gate without tail mould availabe.

4~48 cavity mould as customized.

23 years experience of preform mold specialized manufacture.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: What is replicas in the mold

- Does it mean the supermodel? It's the same mold that has two layers of molds, usually a disposable fork, spoon, crisper, and so on

- Q: The processing method of the mold cavity processing center

- The common processing procedure of the cavity: (milling) around and on both sides, the thickness remains 0.4 minus 0.6rnrn. Two sides of the face and two sides of adjacent side, the surface roughness Ra is 0.8 mu m. The shape of the fitter and the position line of the screw hole. The pattern required the milling out of the cavity, the unilateral remaining balance of 0.3 one-half mm, The machine drill screw holes, thread and so on. 6. Heat treatment. The electrode is used in a rough machining cavity. The worker finishes the polishing. The design calls for chrome plating, etc. The equipment was repaired and inspected.

- Q: The role of the die positioning ring

- The function of the die positioning ring is to make the injection molding machine on the die, to ensure that the sprue of the die is in line with the injection molding machine nozzle position level and complete coincidence

- Q: What kind of mold do you have?

- Die mold Die casting, hot chamber die casting machine with vertical cold chamber die casting, die casting machine with I type cold chamber die casting, die casting machine with full vertical die casting, die casting machine with non-ferrous metals (zinc, aluminum, copper, magnesium alloy die-casting, black metal die-casting mould Non-ferrous metal and black metal pressure casting process 4 Forging die Die forging and large press, forging die, forging die, roll forging die, etc. All kinds of fastener cold heading die, extrusion die, drawing die, liquid forging die etc Metal parts are formed and are pressed and compressed

- Q: What does the mold and the flying model mean

- B: it's the assembly mould. Where can't the qualified fitter fix it

- Q: How does the die rod work? Is it through the press?

- The principle of the work is: in the die and die, the rigid push device doesn't produce the push force, it is in the non-working condition; In open mold close to the biggest trip, installed in the press the slider widget dozen material beam rigidity force transfer to install in the upper die of the push rod, plate, connecting rod and push block, which launched within the die parts or waste.

- Q: How to open the exhaust in the plastic mould exhaust, should notice what?

- The effect of the exhaust tank The exhaust tank has two main functions. One is to exclude the air in the cavity when the fuse is fused. The second is to eliminate all kinds of gases produced during heating. The more thin wall products, the more distant the part of the gate, the opening of the exhaust slot is especially important. For small pieces or precision parts also should attach great importance to the opening of the exhaust slot, because in addition to it can avoid products surface burns and injection quantity is insufficient, also can eliminate the various defects of the products, reduce the pollution of the mould and so on. So how does the exhaust of the cavity be sufficient? In general, if the injection rate is injected at the highest injection rate, it is not left in the product, and it is considered sufficient to exhaust the cavity in the cavity

- Q: How do you handle the die holder

- Mould run burrs this directly associated with the precision of the mould processing 1: CNC processing aspect: parting surface machining with rubber products separately, do protect with mold clamp mouth out at the same time, avoid direct cause in the process of machining die round 2: split electrode aspects: faceted clear Angle of electrode to product rubber electrode, separately die fillet in the EDM process can be avoided

- Q: What is the pull mold

- The process of making sheet metal material into a bowl or can is called a drawing die. For example, the process equipment that makes the aluminum plate into a can is a kind of pull mold.

- Q: What is the mold major

- Industrial production is used for molding, blowing, extrusion, die-casting or forging, metallurgy, stamping and stretching, etc., to obtain the various molds and tools of the required products. In short, the mold is a tool for molding objects, which are made of different parts, and different parts are made of different parts. It mainly USES the physical state of the forming material to realize the processing of the physical appearance.

Send your message to us

Injection Hot Runner PET Preform Mold for Mineral Water Bottle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords