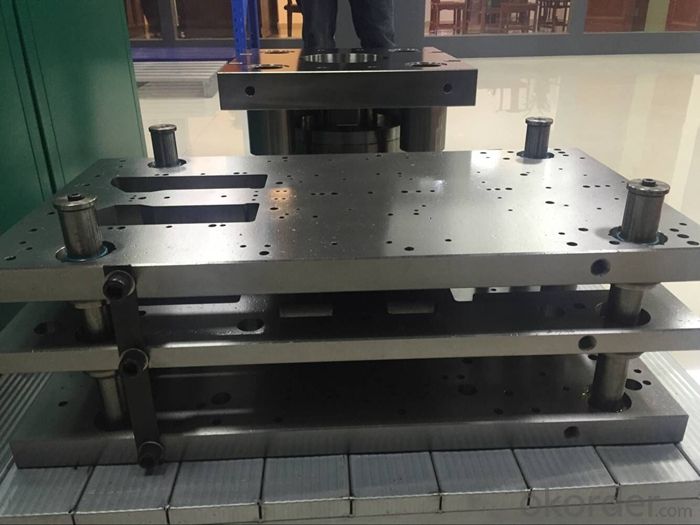

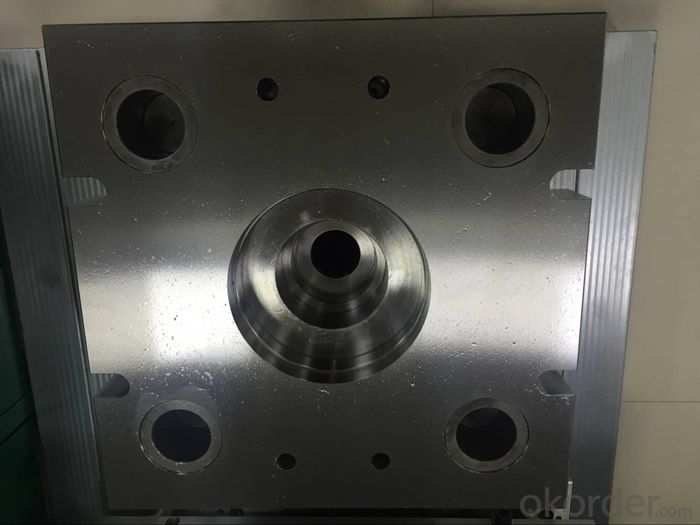

Die-casting Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q: How to choose the injection molding machine when the mould design

- 1, according to the weight of the product, the thickness of the die and the thickness of the die, the width and height of the die.

- Q: The processing method of the mold cavity processing center

- Is the mould inside the groove, and the cavity. Now more than a touch cavity more and more, and most of the high precision, high mould has the characteristics of complexity. Higher up best precision machining center, if the volume is big, also have to gantry machining center, pentahedron gantry machining center, will not have what problem

- Q: What is the difference between the electric casting mould and the CNC working mould

- CNC handicraft processing and die processing are not very different from the processing method, it is the processing medium, the fine carving, the numerical control car and some nc processing equipment. It's very different from being processed. Hand processing mainly processing polymer materials, such as PC, ABS plastic and nylon, and so on, take the massive material carving milling polished lacquer after forming, the final products are generally full scale model of customer research and development, do good as future product identical in appearance. The purpose is self-evident, it is for the product to have a visual confirmation of the shape, color and match of the product before the model, reduce the risk of open mode.

- Q: Is there a difference between die and CNC

- In this industry for a long time, such as the above mentioned anything very tired what some content (which is fitter), such as after contact with these can promote the theory knowledge, can such as the door. Has a common characteristic is one of the two mold design knowledge, the knowledge of the actual mold edge or the manufacture of understand relevant knowledge, above all, the mould design of the road is long, don't be afraid of bitter, in front of the stick behind natural results. The numerical control is relatively less long-term, learn to do, the big deal starts from the foundation. Relatively simple. If you haven't learned it, you can do it, you can do the operator, it's the machine, you move the parts. The treatment is basically between 1,500 and 3,500, and of course there are over 4,000, very few, after all, it's manual labor, it's a piece of work, it shouldn't be done in a few months. The real technology is to learn. The first is programming.

- Q: What is the main meaning of die mold?

- If you want to ask is flying (transliteration) mode, that is will be effected according to the intention of parting made of each piece of steel materials and replacement form closed (product cannot overflow burrs) the process of a block is said to fly.

- Q: What is the difference between mould injection and blow molding?

- The process of injection molding and blow molding is different. Injection molding is the injection + pressure; The blow molding must have the head of the pipe, and the injection molding must have a gate section

- Q: The plastic mould automatically dies and the product drops when it falls

- You can't use the manipulator, the transmission belt is not even more. It's not possible to have a secondary top out, it's a problem that comes out of the top, and you've already written it yourself. A little want to buy something not give money, ha ha. Or semi-automatic. Use hand. Or you can try. Put slope slide board is a bit at the bottom of the mould, manipulate are placed at the side and operation side. When fall apart to make more hole products. Slide plate as close to the mold below (should consider a safe distance) to reduce product drop height.

- Q: Do machine parts need to be moulds?

- The parts of the machine are not required to open the die.I hope my answer will help you.

- Q: The wall thickness of the die is affected by the plastic parts

- For thermoplastic materials, the cooling time is added For thermosetting materials, solidification is not complete.

- Q: How do you buy the die?

- The low value of the item can be used at the expense of the account When buying Borrowing: low value of consumption Borrow: the tax that should pay the tax - value added tax Credit: bank deposits When using Borrowing: manufacturing expense - low value consumables amortization Loan: low value consumables Of course, If the amount is large, it can be amortized.

Send your message to us

Die-casting Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords