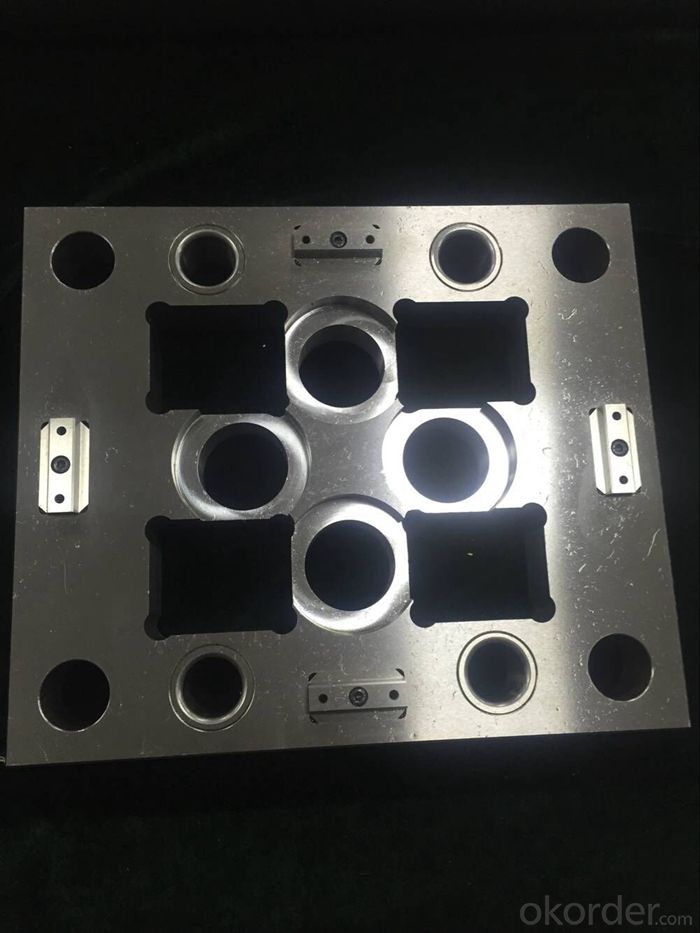

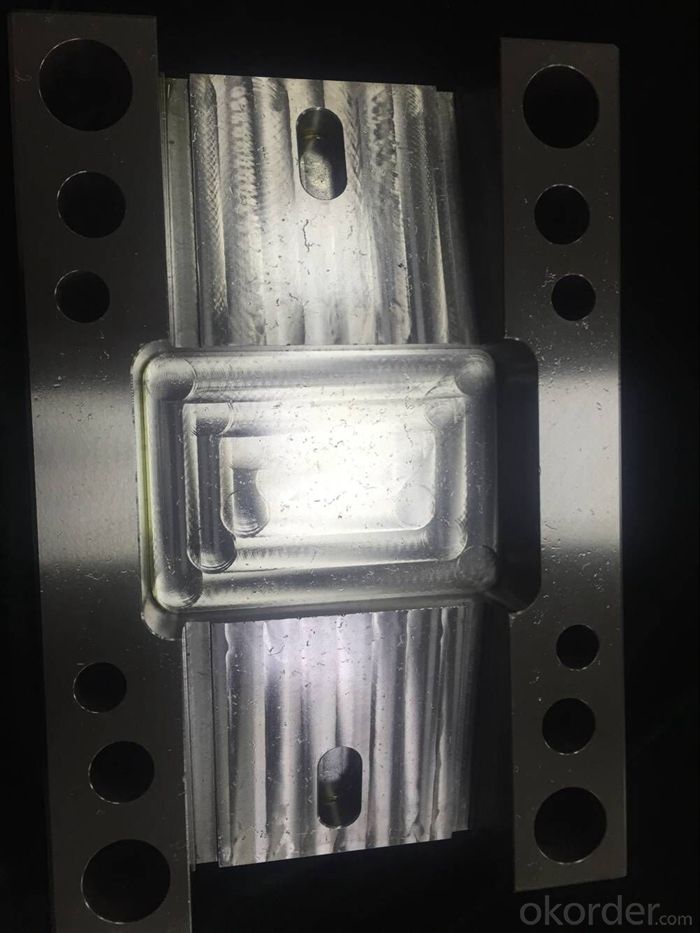

Standard Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q: What is the material of hot pressing die?

- Die steel must have sufficient hardness and abrasion resistance, sufficient strength and toughness. With good machining performance and good decorative pattern, it is commonly used for carbon alloy steel. Commonly used in Japan, yk-30, yellow card 55CC, which is generally used in the factory state, is better after processing.

- Q: What does the mold change mean

- Die setting refers to the change of product structure, and can understand the change of mould structure.

- Q: Can you tell me how the injection molding machine has a large closing line and the batch front?

- Moulding line big flash, must first rule out the mould with no problem, with red lead powder with the mold can be ruled out, if the parting surface not fully fit after clamping to have crack, can produce big flash. It is not a problem to exclude the mold, the process consideration: 1, the material flow is too good, the cylinder temperature is properly lowered

- Q: What does the mold and the flying model mean

- That's the model, Hong Kong. The British side to FIT.I hope my answer will help you

- Q: Injection mold. What does the soft mold mean? What's the difference between a quick one?

- A soft die is a concept that is relative to a hard mold. In the process of component design generally need to verify the design of plastic parts is reasonable, can meet the requirements of the assembly and product design changes may need to be kept. This way, we need to open a sample molds before mass production. Until the design is no longer changed, the initial mass production is limited to a single hole of capacity, which requires a large cavity. In the comparison between soft and hard models, the soft mold is not as good as the hard mold (which is the die life), except for the steel choice. What do you mean by a quick form that you don't understand? Is it a plastic block? If this is the case, then a quick form is not needed, but only a few or dozens of samples can be done, and the cost is high. The average life span of a soft mold is no less than 50,000 modules, even higher. If batch not small plastic parts, often one a hole to use soft model completely can satisfy capacity.

- Q: How many types of molds? Please help me out!

- Die, forging die, stamping die, aluminum casting (casting) using the block, wax mold, plastic mold, metal mould, plastic forming with modeling profile (profile), pressure molding die, glass blowing blowing mould,... This is for use. Cold/hot mold; This is divided by temperature. There is steel die, aluminum die, hard alloy mold; There are wood, sand and wax models; With a plastic mould; This is part of the material that makes the mold. There is a one-off model, multiple sex dies; Permanent model This is from the service life. There are mechanical moulds, space moulds, plastic moulds, building dies, and... This is part of the industry. There can be other calls, there is no uniform rule.

- Q: What is the difference between a large water inlet and a thin nozzle?

- Simply put, the large water mouth is a two-plate mold, and the water port is three plates. Simply say: the big water mouth is two plate molds, the small water mouth is three plank model, two is only the difference one scraper board. The thin water mouth is: more than a big water mouth to push a board. 9, the sex limited gate (gate) : advantage: fast filling, pressure is small, feeding capability is strong, suitable for high viscosity, illiquid plastic, less pressure loss. Disadvantages: sealing water the long, slow cycles, internal stress, Influence on the plastic parts is big, difficult to remove. Restrictive gate (gate) : advantage: shear, friction, viscosity, easy filling, texture clear fast cycle efficiency, reduce internal stress, prevent deformation, less influence on product

- Q: How can silicone and glass steel molds be glued together

- Make plaster mold silicone mold cost is higher, soft silicone mold die, must be listed hard mold industry is hard glass fiber or plaster mold to play a role in the tray, so the cost in terms of silicon rubber, no doubt, the cost will be higher. But FRP mould, despite the cost is relatively low, but because it is a hard mold, difficult mold, also must do slice mode, there are few FRP mould is not very complex, which makes them very trouble. The silicon rubber moulds, on the other hand, are easy to make, prone to mold, and very fine molds, which make the head even a hair.

- Q: Introduction to mould design and manufacturing

- Mold design and manufacture specialized mainly study, plastic injection mold, stamping mold and die casting mould design, and teaching mold fitter, Turner, CNC milling, basic subject and learning mechanical drawing, material, engineering mechanics, mechanical design basis; The software involved is CAD, PROE, MASTERCAM, UG, and CIRMATON

- Q: What are the five systems of plastic mould?

- Good memory, memory in sequence, pouring system, molding system, cooling system, exhaust system, top out system.

Send your message to us

Standard Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords