Plastic Injection PET Preform Mould 24 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

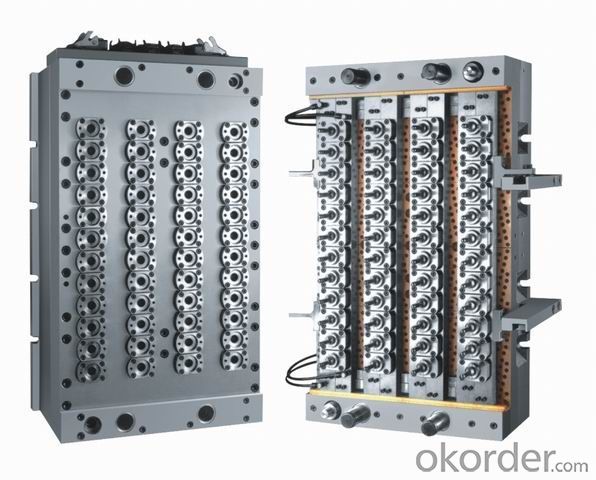

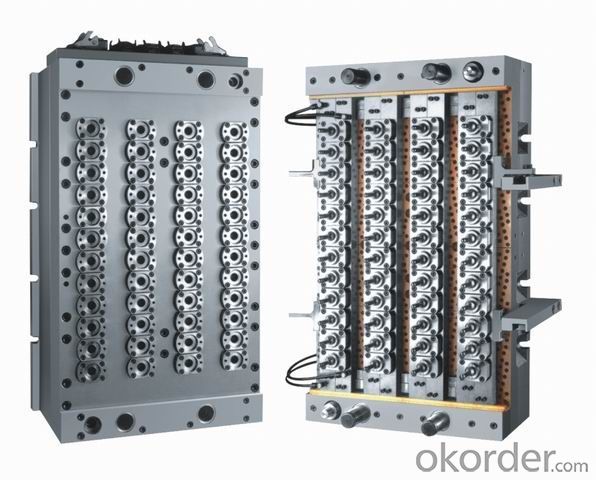

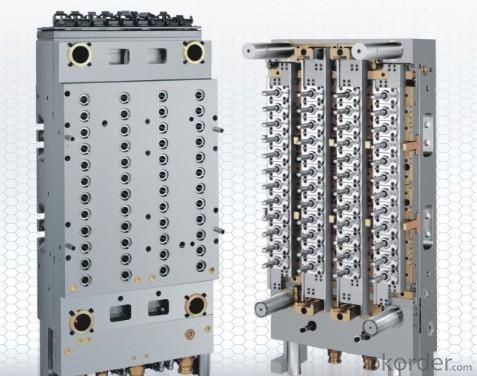

1. Structure of Multi-Cavities PP Preform Mould

Cavity, core and screw neck of steel adopt imported S136 in Sweden, and be heating treatment of hardness up to HRC48-50.

All moulds base do heat treatment of hardness up to HRC 30-35.

Advanced mould design technology:

a) Each cavity self-locks independently and using high precision JAPAN CNC SYSTEM.

b) To ensure low decent ration & precision of the product.

c) Each mould spare part be inserted with durable parts, which are interchangeable. d) In order to improve and achieve high production efficiency, we always design the best cooling system and can match a cooling machine for each mould.

Advanced & accurate valve hot runner & temperature controller, ensure reliability of production and high transparency & brightness of product.

Mould sliding use copper, bottle be achieved FOOD SECURITY standard, and mould life guarantee more than 3 million shots.

2. Main Features of Multi-Cavities PP Preform Mould

No. of Cavity | 12 Cavity | 16 Cavity | 24 Cavity | 32 Cavity | 48 Cavity | 72 Cavity |

18g(cm) | 60*37*43 | 74*37*43 | 80*50*45 | 76*60*48 | 102*60*55 | 110*86*58 |

Weight(kg) | 625 | 770 | 1300 | 1650 | 2500 | 4100 |

28(cm) | 60*37*45 | 74*37*45 | 80*50*48 | 76*60*52 | 102*60*58 | 110*86*62 |

Weight(kg) | 655 | 810 | 1310 | 1800 | 2690 | 4450 |

40(cm) | 60*37*48 | 74*37*48 | 80*50*50 | 76*60*55 | 102*60*62 | 110*86*65 |

Weight(kg) | 700 | 860 | 1360 | 1900 | 2880 | 4670 |

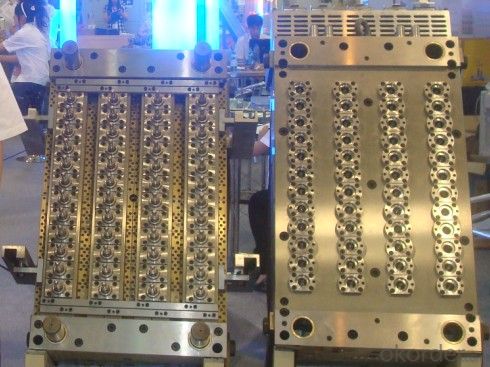

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

. Can supply with both Mold & Molded parts

. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: What is the material of hot pressing die?

- The steel of 5Cr4Mo3SiMnVAl (O12Al) is cold, hot and made of steel. The steel has a high thermal hardness and a higher thermal stability than 3Cr2W8V steel, which is also much better than 3Cr2W8V steel. 4 cr3mo2nivnbb (HD) steel is designed specifically for suitable for hot extrusion black metal (working temperature of 700 ℃ or so) of the new type of steel.

- Q: The processing method of the mold cavity processing center

- Are you a mechanical major? A: do you want any graduation thesis on CNC processing? Tell you that if you are a professional, you don't even know what that means! It is nonsense that you graduate and not graduate

- Q: I have a glass fiber reinforced plastic mould, I want to do with resin imitation jade, don't know way it doesn't, and resin products must use silicone mold can, if use FRP mould can, what kind of release agent is good?

- Possible, stripping before mould to deal with smooth, clean, with a fine sandpaper 2000 water (water is wet grinding), stripping wax to play a few times more, a dry use cotton per dozen grinding smooth play it again, again and again about 5 is preferred

- Q: What kind of mold do you have?

- Mold can be divided into metal mould and non-metal mould. The metal mould is divided into: casting mould (non-ferrous metal casting, steel casting) and forging die etc. Non-metallic mold is also divided into: plastic mould and inorganic non-metallic mould. And according to the material of the mould itself, the mold can be divided into: sand mold, metal mould, vacuum mold, paraffin mold and so on. With the rapid development of polymer plastics, plastic mould and people reference Plastic mould can be divided into: injection molding mold, extrusion molding mold, gas auxiliary molding mould and so on. big The production of non-sheet metal parts - cold heading, die forging, metal mould, etc. The mould Sheet metal discharging, hot-rolled, cold-rolled, hot coil, cold rolled sheet metal processing, deep drawing, integer, bending, punching, blanking, non-ferrous metal casting, powder metallurgy, plastic parts, injection molding, blow molding (plastic bottles), extruded (pipe) mold other categories: alloy mold, metal mold, plastic mold, stamping mold, casting die, forging die, injection mould, die-casting mould, auto mould, thread rolling die

- Q: What is the mold for?

- The mold has cold die and plastic mold, the cold die can extrude the sheet material into the shape you want, and the plastic mold will make the plastic model to be cooled by the melting plastic injection mold

- Q: Is there a difference between die and CNC

- In this industry for a long time, such as the above mentioned anything very tired what some content (which is fitter), such as after contact with these can promote the theory knowledge, can such as the door. Has a common characteristic is one of the two mold design knowledge, the knowledge of the actual mold edge or the manufacture of understand relevant knowledge, above all, the mould design of the road is long, don't be afraid of bitter, in front of the stick behind natural results. The numerical control is relatively less long-term, learn to do, the big deal starts from the foundation. Relatively simple. If you haven't learned it, you can do it, you can do the operator, it's the machine, you move the parts. The treatment is basically between 1,500 and 3,500, and of course there are over 4,000, very few, after all, it's manual labor, it's a piece of work, it shouldn't be done in a few months. The real technology is to learn. The first is programming.

- Q: The plastic mould automatically dies and the product drops when it falls

- We had the same problem before, when it was an ABS product, and then a 20 per cent PC in it solved the problem. We estimate that ABS is not hard enough.

- Q: The stamping dies at the Angle of 90 degrees, the Angle is big or small how to repair.

- That r Angle is on the bend and it's still on the bend. ? On the bend.I hope my answer will help you.

- Q: How do you get the putty on the die?

- The putty has formed a plastic membrane, which can be cleaned by the use of an edible alkali.

- Q: How do you buy the die?

- Borrowing: fixed assets -- molds Tax payable - the VAT (input tax) Loan: bank deposit/accounts payable/stock cash Depreciation time: eliminate the residual value rate general 5%, according to 10 years depreciation So that's the original value minus 5 percent of the original value divided by 10 years divided by 12 months is equal to the cumulative depreciation of every month Above is financial calculation method, but in actual, the mould should be used according to the number for depreciation or abandoned, so to maximize utilization of assets. Of course, the mold when not in use, must pay attention to the maintenance state, not the rust or damage occurred.

Send your message to us

Plastic Injection PET Preform Mould 24 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords