Standard Mould Base/Plastic Injection mould base

- Loading Port:

- Ningbo

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

This product USES S50C material.Accessories are all made of standard guide pin guide bush.The thickness tolerance are processed according to the requirements of 0.00 to 0.02.High surface finish and roughness of standard.Heat resistance and corrosion resistance is very strong, It is used in plastic mold development and manufacturing,composed of various steel plate with parts,It is a complete set of the mould size to make it easier for mold into the injection molding machine installation.specific parameters according to customer requirements.

Specifications

mold base, LKM standard mold base, HASCO standard mold base, DME standard mold base, LKM mold base, HASCO mold base

mold base, LKM standard mold base, HASCO standard mold base, DME standard mold base, LKM mold base, HASCO mold base,mould base, LKM standard mould base, HASCO standard mould base, DME standard mould base, LKM mould base, HASCO mould base

What We Do

Plastic Injection molds. tools making Clear acrylic Injection molding Prototyping and model making Plastic Printing & Welding & Assembly Product 2D&3D design.Reverse-engineering.etc

What We Believe

High quality is the only factor we consider Innovation reduces the cost,increase capacity One-stop solution assures the satisfaction of customer.

We expert in development and fabrication of various high quality moulds with advanced technology and tooling equipments.

High-speed CNC machine Engraving machine Mirror EDM machine Milling and Grinding machine Slow W-EDM machine

We provide one-stop solution from drawings design to final parts

PMMA.ABS.PP.PC.PS.PBT.etc Injection machines equipped with robots Feeders & Dryers. Temp. controlers Assembly line with silk-screen & painting

Advanced CAD and CAM software is adopted in the tool making process.Operated by our experienced engineers.

Moldflow Pro-Engineer Solidworks Unigraphic Auto-CAD

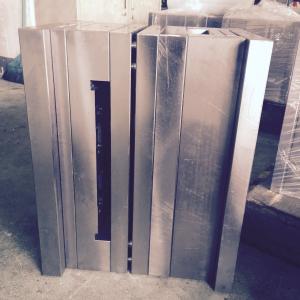

Pictures of the mould base:

- Q: Is the slanting and shoveling chicken in the mold the same thing, shoveling the chicken? Where is it used?

- I have never heard of what it is called The main function of shoveling a chicken, which is also called a slider lock block, is to compress the slider There is another type of spatula in front of the former mold which is the top of the chicken It's double insurance on the back

- Q: Is the digital control the same as the mold? If not, what's the difference?

- There is a difference, the numerical control is a kind of lathe! The mold is a large scale model! They're very different

- Q: What are the molding methods of plastic molding mould?

- Plastic injection mould, it mainly is the most widely used in the production of thermoplastic plastic products of a forming mould, plastic injection molding mold corresponding processing equipment is plastic injection mold and the corresponding equipment is plastic injection moulding machine, plastic in the first place in the bottom of the injection machine heating cylinder heated melting, and then in the injection machine screw or plunger, driven by the injection machine nozzle and mould gating system into the mold cavity, cooling hardening molding, plastic mold release products. Its structure is usually composed of forming parts, pouring system, guiding parts, launching mechanism, tempering system, exhaust system and supporting parts. The manufacturing materials are usually made of plastic mould steel modules, which are mainly made of carbon structural steel, carbon tool steel, alloy tool steels, high speed steel etc. Injection molding processing methods are usually only applicable to hot plastic products production, with the production of injection molding plastic products is very broad, from daily necessities of life to all kinds of complicated mechanical, electrical, vehicle parts are made of injection molding, it is the most widely used in the production of plastic products of a processing method.

- Q: How many products can a mold make?

- Associated with the material of mould and casting method, had better use a scale of 0-8000 pieces of aluminum mould (ordinary sand casting), 0-13000 pieces (molding machine), plastic mold is bad to use, steel is the most strong, but not suitable for manual operation.

- Q: What is the design philosophy of the mould?

- The design and fabrication of precision volumetric mould and die life.

- Q: Mold design and manufacturing to learn which courses

- This major is mainly aimed at machinery manufacturing, and develops the design and manufacture of cold stamping die, type cavity mold and its design and manufacturing. Main courses: mechanical drawing, mechanical design basis, electrician and electronic technology, engineering materials and heat treatment, mould manufacturing technology, mould CAD/CAM. Jobs: workers, molds manufacturing personnel, mechanical maintenance personnel, production management personnel. Tuition is too expensive This is a professional professional, and it's easy to find a job. The school that runs this major is very few in the vocational technical college Jobs: workers, molds manufacturing personnel, mechanical maintenance personnel, production management personnel.

- Q: What is the manufacturing of mould materials

- You're talking about the industry that makes moulds. It is the metallurgical industry that makes mould material. From steelmaking to forging and rolling, it also belongs to heavy industry.

- Q: Is the stainless steel bowl replaceable in the oven?

- I had been sitting in a stainless steel basin for several times, and now I wonder why I spent so much money on the molds, which was much cheaper, a ten-inch dish of ten dollars.

- Q: How can silicone and glass steel molds be glued together

- Answers to these, we need to help your decision, it is not clear can contact the top mold silicone factory, is a professional brand professional manufacturer, not because of their production of plastic mold, think you blindly use silicone mold, silicone rubber, can also use glass fiber reinforced plastic resin is based on the actual situation.

- Q: What is the use of the mold collecting water

- How do you understand that a thick pipe is divided into a few or dozens of thin pipes? A water block switch is required in the middle.

Send your message to us

Standard Mould Base/Plastic Injection mould base

- Loading Port:

- Ningbo

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords