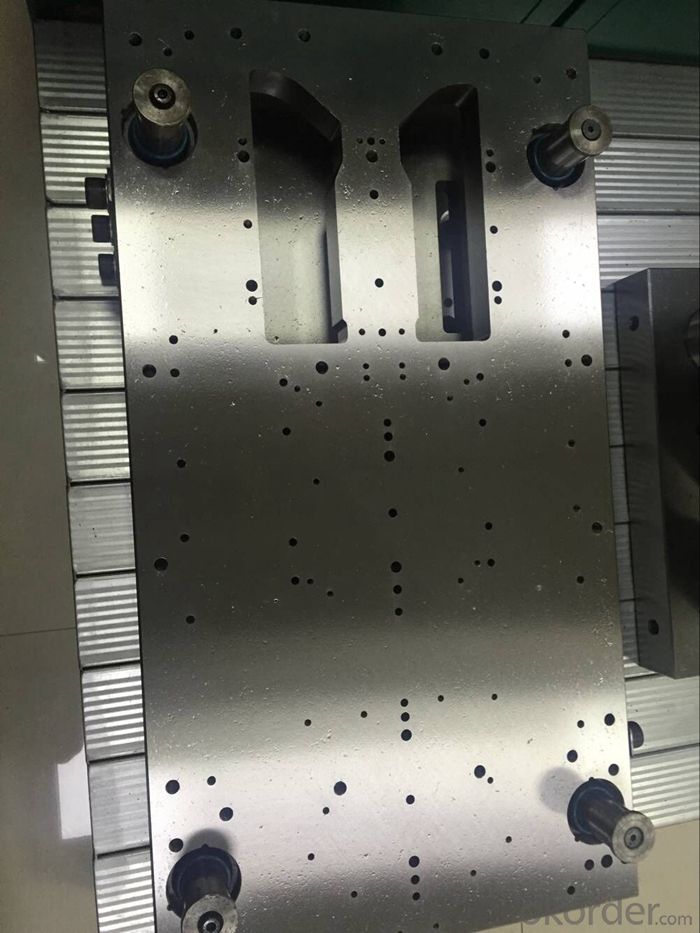

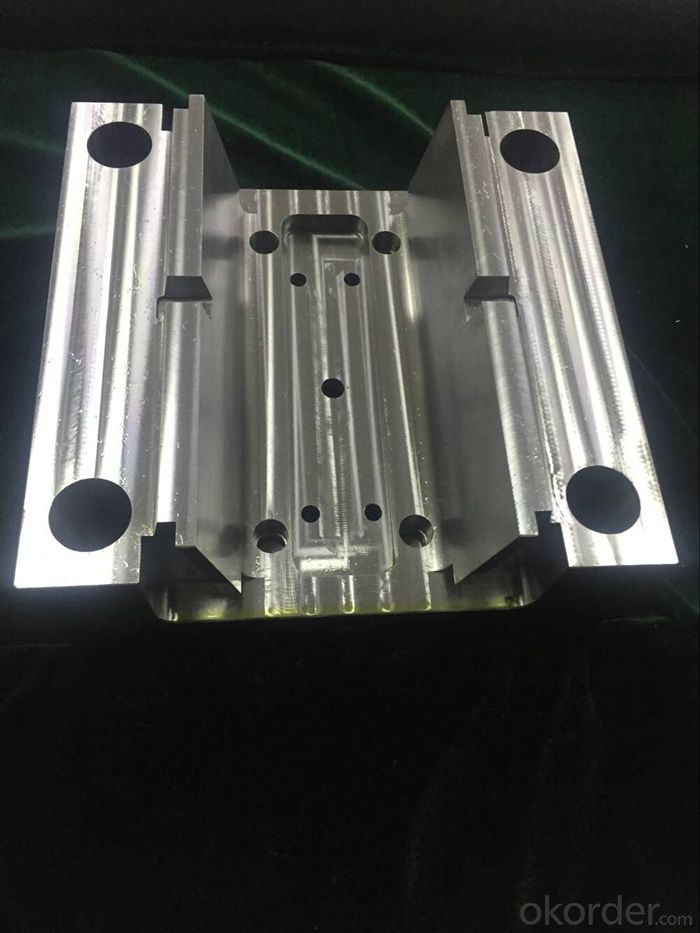

Euro HASCO Mould Frame Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q: How expensive are the molds, or how expensive are they? Which quality is better?

- The molds are more expensive. But efficiency is doubled, and if it's big, it's a lot of work. The quality is better.

- Q: What do you mean by plastic mold injection molding? What's the use?

- The assurance means a fixed pressure on the material in the mold. Because the plastic in the cooling process has the effect of heat bilges cold shrink, especially larger plastic shrinkage, heat bilges cold shrink is very obvious, so when we give the material after a fixed pressure, plastic shrinkage during the cooling process, the mold melt pressure began to decline, with the holding role, and the hydraulic system will automatically forward pressure, progress in the back of the material, added the contraction of the melt front, thus forming prevent products caused by shrinkage deformation. Adjust the pressure of pressure and the time of holding pressure, adjust the product defects such as the flying side, fuse connection and shrinkage mark.

- Q: What are the types of molds?

- From different materials: plastic die, metal stamping die, forging die, metal die casting mould, ceramic die, glass mold, glass steel mould etc. There are many types of each.

- Q: Injection mold. What does the soft mold mean? What's the difference between a quick one?

- A soft die is a concept that is relative to a hard mold. In the process of component design generally need to verify the design of plastic parts is reasonable, can meet the requirements of the assembly and product design changes may need to be kept. This way, we need to open a sample molds before mass production. Until the design is no longer changed, the initial mass production is limited to a single hole of capacity, which requires a large cavity. In the comparison between soft and hard models, the soft mold is not as good as the hard mold (which is the die life), except for the steel choice. What do you mean by a quick form that you don't understand? Is it a plastic block? If this is the case, then a quick form is not needed, but only a few or dozens of samples can be done, and the cost is high. The average life span of a soft mold is no less than 50,000 modules, even higher. If batch not small plastic parts, often one a hole to use soft model completely can satisfy capacity.

- Q: Mold design and manufacturing to learn which courses

- Learn how to design the mold design so many theories, more to point factory actual experience is true, slowly experience

- Q: What is the difference between mould injection and blow molding?

- Injection molding is used to make the mold and then inject the plastic into the mould. Blow molding is used to make a good plastic moulds after heating softening in the embryo, the embryo within the join high pressure air, thinning of the tensile softening of the embryo, formation and mould the same products. Injection molding can make a very complex plastic product, and you can say what shape you want to make. Blow molding can only make hollow products, such as drink bottles and some tool boxes. The moulds are very expensive and the processing is more expensive. Blow molding and processing are cheaper

- Q: What is the difference between a large water inlet and a thin nozzle?

- The difference between a large water inlet and a thin water nozzle: 1, from the entrance of the entrance to the glue mouth: one is the point gate (directly from the product to the glue) usually called the thin nozzle mold; One is from the side into the glue, gate is relatively big usually call gate mould (but sometimes think products turn into the glue need will do fine shuikou gate into the glue, structure and three board mould) Different from the structure of the mould: the two plates are usually called the large water port molds. There are two kinds of thin water mouth mould and thin water mouth mould.

- Q: What is a molds? What is the difference between die and die?

- 1, the modular fixture is called the tooling and fixture, as most of product molding need processing after coming out, which requires on the machine processing, and on the machine requires fixture, so the evaluation for the production of a product when it need to evaluate how much you need to do to die fixture, name. 2, mould, industrial production to injection molding, blow molding, extrusion, die casting or forging molding, smelting, the methods of stamping products of various molds and tools required. In short, the mold is a tool for molding objects, which are made up of various parts, and different parts are made of different parts. It mainly USES the physical state of the forming material to realize the processing of the physical appearance. There is the title of "mother of industry".

- Q: Make the mold with the dough

- Don't know what material are you going to make up, but the estimate is made of liquid class can be solidified material. So note that, if the material to be heated to a liquid to prevent the high temperature burn silly putty cavity (silly putty is usually made of flour and salt). In addition to prevent leakage of liquid. (recommended materials choose gesso)

- Q: What is the relation between the mould and the clamp

- How to say, big is all belong to the mechanical industry, say to the relation, I personally think to make the mold to be able to make a fixture, do jig not necessarily can make the mold. The mold needs more experience, and the fixture needs more creative thinking. The common fixture is non-target, but the mold is not the standard, but is roughly the same type. Such as stamping die of blanking die, the structure is basically all the same, just in the middle of the blanking shape, templates, fixed plate, stripper plate up and down, up and down mold core, unloading spring, guide pin guide sleeve is involved. There are many different types of jig, but the key is to locate and clamp these two core ideas. Ok.

Send your message to us

Euro HASCO Mould Frame Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords