PET Preform Injection Moulding China OEM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Advantages of Multi-Cavities PP Preform Mould

Characteristics of the production line

First: PET material→dehumidify→load material→injection machine→ preforms

Second: PET Preforms →heat preform → stretch → blowing → bottles

Cap on in the injection molding machine is completely automated production, its production process is as follows::

PP material→load material→dry→heat material →injection→cooling molding →preforms→cap

Injection molding machine: Adopting Europe technology, hydraulic unit adopts proportional pressure and flow control, the pressure and the speed can be adjusted, stable movement curve and gentle shock, the computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to use. Close-loop PID temperature control with the advantage of high precision. The operating table of the injection molding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators’ safety.

Mould: Our mould producing center produces exact mould, adopts the high grade material to make. The perform mould uses the hot runner technology, inside uses the imported steel, the surface’s brightness is very high and the service time is very long.

1.The design of equipment is logical, easily operation.

2.The automatic level is very high, the wage is very little.

3.Using famous imported hydraulic, electrical, sealing parts, the trouble is low.

4.No matter what the product’s outside or inside, they can get the best guarantee, the good products rate can be above 99%

2. Main Features of Multi-Cavities PP Preform Mould

Mouse mould design is a brain demanding work which has no copy action.

When designing a mouse mould the method of modification should be taken into consideration and should have enough space for modification.

The devices of the mouse mould should meet the standard of anti-grating and long-life shots.

The manufacturing skill and time are different with the hardness and stretchiness of the material.

Because of its precision, most of work has to be done by manual work.

Mould of high quality should be qualified with good surface manufacturing and precision

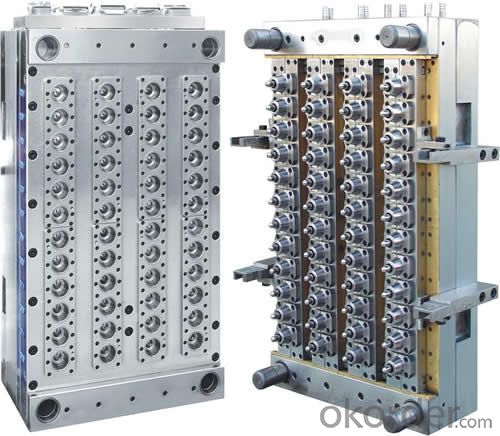

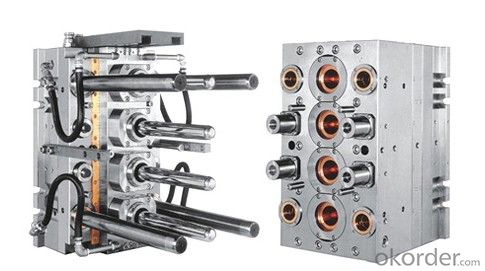

3. Images of Multi-Cavities PP Preform Mould

4. Instruction of Multi-Cavities PP Preform Mould

We complete mould making line, from the mould's design, processing, assemblage, test to perfect mould. The mould designed by AutoCAD system, PRO-Engineer system, Solidworks system etc.

For the mould processing, we use precision machines and CNC machine.

For the mould assemblage, we have experienced workers who has more assemblage experience. With carefully work attitude and rich experience, make our mould quality better and better.

For the mould test, our company also make all kinds types of injection molding machine, this is our excellent, as other mould company not have this advantage for good testing.

For PET preform mould, there are 8 cavities, 16cavities, 24cavities, 32 cavities 48 cavitied and 72cavitied for choice.

PET material because of its exceptional performance, are generally used two-step molding process, by the preform injection molding machine to produce a 24-hour After cooling, the internal molecular structure of their re-arranged in an orderly manner, and blowing for the next step to create good conditions, so that more excellent blowing performance products. Such as the famous Coca-Cola Company is currently using this technology.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: What is the role of the guide in the mould

- The "guide column" in the mould is also called "guide column".I hope my answer will help you

- Q: What effect is the flange of the die

- Flanges are concentric with the jw, flanged, and the nozzle of the injection-molding machine, the flanged design corresponds to the size of the machine. You've seen the big hole in the injection molding machine. That's a match for the flange

- Q: The role of cryogenic processing of die material

- Cryogenic processing can improve the performance of various materials. In the mould materials, it is mainly possible to improve the wearability, the prolonged impact fatigue strength, the ductility of the material and the internal deformation.

- Q: What is the difference between the p20 mould steel and the nak80-b mould steel

- It's completely different, the composition is different, P20 is 3Cr2Mo, and NAK80 is 10Ni3MnCuAl

- Q: What do you mean by plastic mold injection molding? What's the use?

- According to the contraction and cooling effect. If the workpiece after the mold shrinkage will increase the holding time, if the workpiece after the mold is soft, finalize the design is not good, also want to try to increase the pressure maintaining and cooling time in injection molding process, the solution for cooling and contraction, but due to the screw to continue to move forward slowly, make the pipe material in the melt to continue into the cavity, to supplement the need of product shrinkage, called pressure. Ie, to prevent the product shrinkage, use pressure production is stable. The holding also can adjust the size of the product size, and there will be no weld lines, sag, flash and buckling deformation.

- Q: What is the purpose of the mould

- If you haven't seen it, one or two words are not clear, and the man above has given the standard answer. If you still don't understand, you would think so, such as shoes, if you want to shoe shape, inside a shoe last to the shoe, and then the shoe last is mould. For example, the brick that builds a house, all use a square box to do, this four box also is the mold. The clay POTS used in the neolithic people were also made of molds. For example, buckets, lunch boxes, water cups, home appliances, cars, etc. All you see and use are made of molds. It can be said that if there were no moulds, there would be no civilization! Modern westerners to die is the origin of the rules for German (ancient former German emperor ruled by the Swedish region) invented by the shoemaker, this is in order to prove that westerners are smarter than the east.

- Q: The effect of mould preheating and several methods of preheating

- Mould temperature machine (oil) heating: the heating is even, the temperature adjustment adopts intelligent control, the temperature control accuracy is high, can meet the strict requirement of high craft standard. The operation control and safety monitoring device is fully complete, the heating process is fully automatic, the operation is simple, and the installation is convenient. Closed circuit heating, low heat loss, significant energy saving effect, no environmental pollution, wide range. The drawback is that heating is transmitted by heat, which is slower

- Q: How is the die in the manufacturing industry

- If you are a production company, you can buy it as a tool and sell it as a material sale. Purchase: low value consumables - molds Taxes should be paid in the form of VAT Bank deposits (or accounts payable) Sales: bank deposits (or accounts receivable) Other business income - material sales Tax payable - value-added tax Cost of transfer: other business costs Low value of the loan - molds Welcome to use the "fiscal and tax question-and-answer community" for financial advice

- Q: What is a molds? What is the difference between die and die?

- The mold is not the same as the treatment Generally speaking, the mould is the outside mold that produces the product The treatment is usually for the convenience of the process and the test

- Q: What is the mold major

- Mold is the mould profession, do some machine parts, processing machine, very dry and tasteless, do not mind to read

Send your message to us

PET Preform Injection Moulding China OEM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords